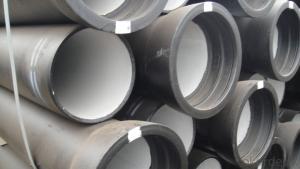

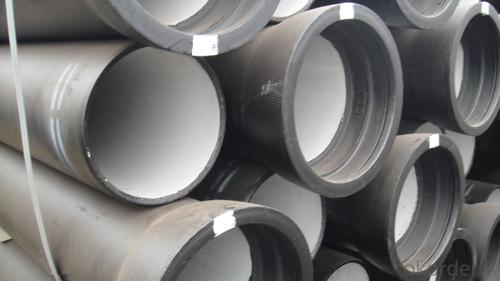

Ductile Iron Pipe For Water Project On Sale with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Are ductile iron pipes suitable for irrigation systems?

- Yes, ductile iron pipes are suitable for irrigation systems. They are known for their strength, durability, and corrosion resistance, making them a reliable choice for transporting water in agricultural settings. Additionally, ductile iron pipes can withstand high pressure and are resistant to external loadings, making them ideal for irrigation systems that require efficient water distribution.

- Q: Can ductile iron pipes be used for underground steam distribution systems?

- Yes, ductile iron pipes can be used for underground steam distribution systems. Ductile iron is a type of cast iron that has been treated with magnesium to make it more flexible and resistant to cracking. This makes it suitable for use in underground applications where the pipes may need to withstand high pressure and temperature conditions, such as in steam distribution systems. Ductile iron pipes have excellent strength and durability, which makes them capable of handling the extreme conditions associated with steam distribution. Additionally, their corrosion resistance properties make them a reliable choice for long-term use in underground environments. However, it is important to note that proper insulation should be used to prevent heat loss and ensure the efficiency of the steam distribution system.

- Q: How are ductile iron pipes protected against internal scaling or buildup?

- Ductile iron pipes are protected against internal scaling or buildup through various methods. One of the most common methods is the application of cement mortar lining on the inner surface of the pipes. This lining acts as a protective barrier, preventing the formation of scale or buildup and ensuring a smooth flow of water or other fluids. Additionally, the pipes can be coated with a layer of polyethylene or other suitable materials to provide an extra level of protection against scaling or buildup. This coating acts as a barrier between the water and the iron surface, reducing the chances of corrosion or scale formation. Regular maintenance and cleaning are also crucial in preventing internal scaling or buildup in ductile iron pipes. Flushing the pipes with high-pressure water or using chemical treatments can help remove any accumulated scale or debris, ensuring the pipes remain clean and functional. Furthermore, proper water treatment is important to minimize the risk of scaling or buildup. Implementing appropriate water treatment processes, such as pH adjustment or the use of corrosion inhibitors, can help maintain the quality of the water and prevent the formation of scale or buildup inside the pipes. In conclusion, ductile iron pipes are protected against internal scaling or buildup through various measures, including cement mortar lining, pipe coating, regular maintenance, cleaning, and proper water treatment. These measures ensure the longevity and efficiency of the pipes, minimizing the chances of clogging or reduced flow capacity.

- Q: Are ductile iron pipes suitable for road crossings?

- Yes, ductile iron pipes are suitable for road crossings. Ductile iron is a strong and durable material that can withstand heavy loads and traffic. It has high tensile strength and flexibility, making it an ideal choice for underground installations beneath roads. Additionally, ductile iron pipes are resistant to corrosion and have a long lifespan, making them a reliable option for road crossings.

- Q: How can the ductile iron pipe depress the elbow so as to prevent it from being opened?

- Elbow materials are cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, nonferrous metals and plastics.

- Q: How do ductile iron pipes handle dynamic loads?

- Ductile iron pipes possess remarkable strength and durability, enabling them to effectively manage dynamic loads. These pipes exhibit a high resistance to bending and can endure the pressure and stress exerted on them when exposed to dynamic loads, such as water hammer or ground movement. The distinctive composition of ductile iron, which includes a small amount of carbon and the addition of magnesium, produces a structure that is both robust and flexible. This combination allows the pipes to flex when impacted by dynamic loads, rather than fracturing or breaking like other materials. Moreover, ductile iron pipes demonstrate a superior impact resistance, enabling them to absorb and distribute the energy generated by dynamic loads throughout their structure. This capability to dissipate energy effectively minimizes the risk of pipe failure and ensures the longevity of the pipeline system. Additionally, ductile iron pipes exhibit excellent stress distribution properties, ensuring that the load applied to the pipes is evenly dispersed along their length. This feature serves to prevent localized stress concentrations and reduces the likelihood of damage or failure. To summarize, ductile iron pipes are specially designed to handle dynamic loads with utmost efficiency. Their strength, flexibility, impact resistance, and stress distribution properties make them highly suitable for applications where dynamic loads are a concern, guaranteeing the reliability and longevity of the pipeline system.

- Q: What are the different types of joints used with ductile iron pipe?

- The different types of joints commonly used with ductile iron pipe include push-on joints, mechanical joints, restrained joints, flanged joints, and welded joints. Each type of joint offers different benefits and is used depending on the specific requirements of the installation.

- Q: Can ductile iron pipes be used in sewage treatment plants?

- Yes, ductile iron pipes can be used in sewage treatment plants. Ductile iron pipes are a commonly used material in sewage systems due to their durability, strength, and corrosion resistance. They are able to withstand the harsh conditions often present in sewage treatment plants, such as corrosive wastewater and high-pressure environments. Ductile iron pipes are also highly resistant to cracking and provide long-term reliability, making them a suitable choice for sewage treatment plants where a reliable and efficient sewage system is crucial.

- Q: Are ductile iron pipes resistant to chemicals?

- Yes, ductile iron pipes are highly resistant to a wide range of chemicals, making them suitable for various applications involving corrosive substances.

- Q: How is ductile iron pipe different from other types of pipes?

- Ductile iron pipe is different from other types of pipes in several ways. Firstly, ductile iron pipe is known for its exceptional strength and durability. It is made from a unique composition of iron, carbon, and other alloying elements, which gives it superior mechanical properties compared to other types of pipes. This makes ductile iron pipe highly resistant to external forces and pressure, making it ideal for underground installations, water mains, and sewer systems. Secondly, ductile iron pipe has excellent corrosion resistance. It is typically lined with a cement mortar or an internal coating, which provides a protective barrier against corrosion and extends the pipe's lifespan. This makes ductile iron pipe highly suitable for carrying water and other fluids, as it prevents contamination and maintains the quality of the transported material. Furthermore, ductile iron pipe offers a high degree of flexibility. Unlike more rigid pipe materials like cast iron, ductile iron pipe has the ability to withstand moderate deflection and ground movement without breaking or cracking. This flexibility makes it less prone to failure and reduces the need for costly repairs or replacements. Lastly, ductile iron pipe is relatively easy to install and maintain. It is typically available in long lengths, which minimizes the number of joints required. Additionally, the pipe's mechanical properties and corrosion resistance make it less susceptible to damage during installation or operation, resulting in lower maintenance costs over time. In conclusion, ductile iron pipe stands out from other types of pipes due to its exceptional strength, corrosion resistance, flexibility, and ease of installation. These qualities make it a reliable and cost-effective choice for various applications, especially in the water and wastewater industry.

Send your message to us

Ductile Iron Pipe For Water Project On Sale with Top Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords