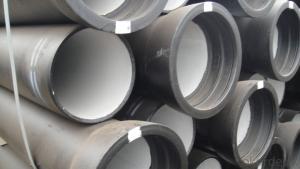

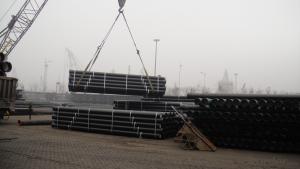

Ductile Iron Pipe For Water Project On Sale with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: What are the common methods for cutting ductile iron pipes?

- Some common methods for cutting ductile iron pipes include using a handheld reciprocating saw with a metal-cutting blade, using a portable bandsaw, using a chop saw with a diamond-tipped blade, and using a pipe cutter specifically designed for ductile iron pipes. Additionally, some professionals may also use oxy-fuel or plasma cutting methods for larger diameter pipes.

- Q: What is the expected joint deflection capability of ductile iron pipes?

- The expected joint deflection capability of ductile iron pipes can vary depending on several factors. However, in general, ductile iron pipes have a higher joint deflection capability compared to other types of pipes. The joint deflection capability refers to the ability of a pipe joint to accommodate angular deflection or misalignment during installation or due to ground movement. Ductile iron pipes are known for their flexibility, which allows them to withstand external forces and movements without compromising their structural integrity. The expected joint deflection capability of ductile iron pipes typically ranges from 1 to 5 degrees, depending on the pipe diameter and wall thickness. This means that the pipes can safely accommodate angular deflection within this range without causing leakage or failure. It is important to note that the joint deflection capability can also be influenced by factors such as the type and quality of the joint restraint system, soil conditions, installation techniques, and pipe alignment. Proper installation practices and adherence to manufacturer guidelines are crucial in ensuring optimal joint deflection capability. Overall, ductile iron pipes are designed and manufactured to have a significant joint deflection capability, making them suitable for a wide range of applications, including water distribution, sewer systems, and industrial piping networks.

- Q: How does ductile iron pipe perform in areas with high traffic loads?

- Ductile iron pipe performs exceptionally well in areas with high traffic loads. Due to its superior strength and durability, it is highly capable of handling heavy loads and withstanding the impact caused by vehicular traffic. Ductile iron pipes have a high resistance to bending and cracking, making them ideal for applications in roadways, highways, and other high traffic areas. The high strength of ductile iron pipe allows it to distribute the weight and pressure exerted by heavy traffic loads more effectively, reducing the risk of deformation or failure. This makes it a reliable choice for transporting water, sewage, and other fluids in areas where heavy vehicles are commonly present. Additionally, ductile iron pipe has excellent corrosion resistance, which further enhances its performance in high traffic areas. It can withstand exposure to various environmental conditions, including moisture, chemicals, and abrasion, without compromising its structural integrity. This makes it a long-lasting and cost-effective solution, as it requires minimal maintenance and has a long service life. Furthermore, ductile iron pipe's smooth internal surface minimizes friction and allows for efficient flow of liquids, reducing energy consumption and maximizing the pipe's hydraulic capacity. This is particularly beneficial in areas with high traffic loads, where the demand for water or wastewater transportation is often greater. In summary, ductile iron pipe is a reliable and durable choice for areas with high traffic loads. Its strength, resistance to bending and cracking, corrosion resistance, and efficient flow characteristics make it an excellent option for transportation systems in roadways, highways, and other heavily trafficked areas.

- Q: Can ductile iron pipes be used in culvert or storm sewer applications?

- Yes, ductile iron pipes can definitely be used in culvert or storm sewer applications. Ductile iron pipes are known for their strength, durability, and flexibility, making them ideal for such applications. They have the ability to withstand heavy loads, resist corrosion, and handle high flow rates, making them a reliable choice for culverts and storm sewers. Ductile iron pipes also have a long service life and require minimal maintenance, further adding to their suitability for these applications. Additionally, ductile iron pipes can be easily installed and are available in various sizes and configurations to meet the specific requirements of culvert or storm sewer projects. Overall, ductile iron pipes are a proven and widely used option for culvert or storm sewer applications, providing efficient and long-lasting performance.

- Q: Can ductile iron pipes be used for stormwater management systems?

- Indeed, stormwater management systems can utilize ductile iron pipes. Renowned for their robustness and lastingness, ductile iron pipes prove fitting for diverse purposes, including stormwater management. These pipes exhibit resistance against corrosion and possess the ability to endure immense pressure, rendering them perfect for transporting stormwater runoff. Moreover, ductile iron pipes boast an extended lifespan, thereby minimizing the necessity for frequent replacements and upkeep. All in all, when it comes to stormwater management systems, ductile iron pipes serve as a dependable option.

- Q: What are the typical joint sealing requirements for ductile iron pipes?

- The typical joint sealing requirements for ductile iron pipes include the use of rubber gaskets or mechanical joints. Rubber gaskets are commonly used for joint sealing in ductile iron pipes as they provide a reliable and flexible seal. These gaskets are typically made of synthetic rubber materials that are resistant to water, chemicals, and other environmental factors. Mechanical joints, on the other hand, are another common method of joint sealing in ductile iron pipes. These joints consist of a mechanical device that connects the pipes together and provides a watertight seal. Mechanical joints are typically designed to allow for some movement and flexibility, which is especially important in areas where ground movement or settlement may occur. In addition to using rubber gaskets or mechanical joints, it is also important to properly clean and prepare the pipe surfaces before making the joint. This may involve removing any dirt, debris, or old joint material from the pipe ends to ensure a proper seal. The joint should then be assembled according to the manufacturer's instructions, ensuring that the gasket or mechanical joint is correctly positioned and tightened to the recommended torque. Overall, the typical joint sealing requirements for ductile iron pipes involve the use of rubber gaskets or mechanical joints, proper cleaning and preparation of the pipe ends, and following the manufacturer's instructions for assembly. These requirements are essential for ensuring a watertight and durable joint that can withstand the pressures and environmental conditions commonly encountered in ductile iron pipe systems.

- Q: What are the different types of joints used in ductile iron pipes?

- The different types of joints used in ductile iron pipes include push-on joints, restrained joints, mechanical joints, flanged joints, and welded joints.

- Q: What is the maximum allowable deflection for ductile iron pipes?

- The maximum allowable deflection for ductile iron pipes is typically specified by industry standards and guidelines, such as those provided by the American Water Works Association (AWWA) and the Ductile Iron Pipe Research Association (DIPRA). These standards specify the maximum allowable deflection as a percentage of the pipe's outside diameter. According to AWWA C150/A21.50 and DIPRA's Technical Bulletin No. 10, the maximum allowable deflection for ductile iron pipes can vary depending on factors such as pipe size, wall thickness, and soil conditions. However, a common rule of thumb is that the maximum allowable deflection should not exceed 3% of the pipe's outside diameter. It is important to note that exceeding the maximum allowable deflection can result in potential structural issues and reduced performance of the ductile iron pipe. Therefore, it is crucial to adhere to the industry standards and guidelines to ensure the proper installation and functioning of ductile iron pipes.

- Q: Can ductile iron pipe be recycled?

- Yes, ductile iron pipe can be recycled. It is a highly recyclable material that can be melted down and reused in the production of new ductile iron products. Recycling ductile iron pipe helps reduce waste and conserves natural resources.

- Q: How do ductile iron pipes handle pipe deflection?

- Ductile iron pipes are known for their exceptional strength and flexibility, which allows them to handle pipe deflection effectively. Pipe deflection refers to the bending or curving of a pipe from its original straight alignment. When subjected to external forces, such as soil movement or heavy loads, ductile iron pipes have the ability to flex and adjust without fracturing or breaking. This is due to their unique composition, which includes nodular graphite inclusions that provide excellent ductility. The flexibility of ductile iron pipes enables them to absorb and distribute stress evenly along the pipe wall, preventing concentrated points of strain that could lead to failure. This characteristic allows the pipes to accommodate ground movement, settlement, and other external factors that may cause deflection. Additionally, ductile iron pipes have a high modulus of elasticity, which means they can withstand significant deformation before reaching their ultimate limit. This property allows the pipes to maintain their structural integrity even when subjected to substantial deflection. Furthermore, the joint system used in ductile iron pipe installations contributes to their ability to handle pipe deflection. The restrained joint design ensures a tight and secure connection between pipe sections, reducing the potential for joint separation or leakage under deflection-induced stress. Overall, ductile iron pipes have excellent resistance to pipe deflection. Their flexibility, high modulus of elasticity, and reliable joint system make them a preferred choice for various applications, including water distribution, wastewater management, and sewer systems.

Send your message to us

Ductile Iron Pipe For Water Project On Sale with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords