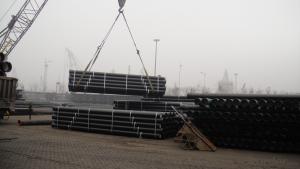

Ductile Iron Pipe For Water Project On Sale From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: What are the different types of ductile iron pipe joints?

- There are several different types of ductile iron pipe joints commonly used in various applications. These joints are designed to provide a strong and reliable connection between pipes, ensuring efficient fluid transfer and preventing leaks. Some of the most common types of ductile iron pipe joints include: 1. Push-on Joint: This type of joint is easy to install, as it does not require any special tools or equipment. The spigot end of one pipe is inserted into the bell end of another pipe, creating a tight seal. A rubber gasket is usually used to enhance the joint's resistance to leaks. 2. Mechanical Joint: Mechanical joints are commonly used in water and wastewater applications. They consist of a gland, a rubber gasket, and a follower gland. The pipe ends are pushed into the gland, and the follower gland is tightened, compressing the rubber gasket and creating a secure connection. 3. Restrained Joint: Restrained joints are specifically designed to withstand high internal and external forces such as water pressure or soil loadings. These joints typically use a rubber gasket and a restraining mechanism, such as a bolt or wedge, to prevent the pipe from moving or separating under stress. 4. Flanged Joint: Flanged joints are commonly used in large diameter pipes or applications requiring frequent disassembly. Each pipe end is equipped with a flange, which is then bolted together with the use of gaskets to create a strong connection. Flanged joints provide easy access for maintenance or repairs. 5. Welded Joint: Welded joints involve heating the pipe ends and fusing them together to form a permanent connection. This type of joint is commonly used in high-pressure applications where a reliable and leak-free connection is crucial. Welded joints require skilled labor and specialized equipment. It is important to choose the appropriate type of joint based on the specific application, pipe size, and operating conditions to ensure the integrity and longevity of the ductile iron pipe system. Consulting with a professional engineer or pipe manufacturer can help determine the most suitable joint for a particular project.

- Q: Can ductile iron pipe be used for water treatment plant applications?

- Ductile iron pipe is indeed applicable for water treatment plant purposes. Renowned for its robustness and endurance, this type of pipe is well-suited for the conveyance of water and other liquids in diverse industrial environments, such as water treatment facilities. Its exceptional resistance to corrosion and capacity to endure substantial pressure and temperature make it an ideal selection for scenarios where the pipe is exposed to chemicals, disinfectants, and other treatment procedures. Moreover, the installation, maintenance, and repair of ductile iron pipe are straightforward, rendering it a cost-efficient alternative for water treatment plant infrastructure.

- Q: Can ductile iron pipes be used for geothermal energy systems?

- Certainly, geothermal energy systems can utilize ductile iron pipes. Ductile iron, being a robust and long-lasting substance, possesses the capacity to endure the frequently encountered elevated temperatures and pressures in geothermal energy systems. Its ability to resist corrosion and exhibit high tensile strength renders it a perfect selection for conveying geothermal fluids. Furthermore, the ease of joining ductile iron pipes permits flexibility and adaptability during the design and installation phases. All in all, ductile iron pipes prove to be a trustworthy and economically viable alternative for geothermal energy systems.

- Q: Can ductile iron pipe be used for fire protection systems?

- Yes, ductile iron pipe can be used for fire protection systems. Ductile iron pipe has excellent resistance to fire, making it a suitable choice for fire protection applications. It is known for its strength, durability, and ability to withstand high temperatures, making it reliable for transporting water or other fire suppression agents.

- Q: Can ductile iron pipe be used for irrigation systems?

- Yes, ductile iron pipe can be used for irrigation systems. Ductile iron is a strong and durable material that can withstand the high pressure and constant flow of water required for irrigation systems. It is resistant to corrosion, making it suitable for underground applications where it may come into contact with moisture and soil. Additionally, ductile iron pipes have the advantage of being able to handle heavy loads, which is important for irrigation systems that may require the use of heavy machinery or vehicles. Overall, ductile iron pipe is a reliable and long-lasting choice for irrigation systems.

- Q: What's the function of the cement mortar lining of ductile iron pipes?

- Active protection is superior to barrier coating, cement mortar lining, and a stable hydroxide film formed on the surface of ductile iron and steel pipe to form a protective layer. This kind of protective coating has excellent antiseptic properties because they spontaneously protect themselves even in discontinuous linings. A polymer in sharp contrast, such as an epoxy lining, is also barrier coating, but only if 100% is applied without leakage. Any interruption or leakage will cause corrosion.It has been documented that cement mortar and cement mortar have been applied to the field of water transportation and can meet the water quality standards for a long time. Some standards still apply to the world. Cement mortar does not support microbial growth. In the case of corrosive water or low flow rate (prolonged stagnation), it is better to use cement mortar lined pipes because it can maintain high pH values in the pipe. This does not cause health problems and can be prevented by very simple sealed coating methods. The natural characteristics of the sealing coating provide the best protection for the inner wall of the pipe, while ensuring that all the water quality indexes meet the quality requirements, low cost and high efficiency.

- Q: Can ductile iron pipes be used for water supply networks?

- Yes, ductile iron pipes can be used for water supply networks. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them an ideal choice for transporting water. Additionally, their flexibility allows for easy installation and maintenance, making them a popular option for water supply networks.

- Q: Ductile iron pipe is how many years warranty

- Ductile iron pipe is a kind of cast iron pipe. In quality, the spheroidization of cast iron pipes is controlled to be 1-3 (spheroidization rate 80%), so the mechanical properties of the material have been better improved, with the nature of iron and the properties of steel. Ductile cast iron pipe after annealing, the microstructure is ferrite and pearlite, good mechanical properties, excellent corrosion resistance, good ductility, good sealing effect, simple installation, mainly for municipal, industrial and mining enterprises, water supply, gas, oil etc..

- Q: What are the different lining materials available for ductile iron pipe?

- There are several different lining materials available for ductile iron pipes. These linings are used to protect the pipe from corrosion and extend its lifespan. Some common lining materials include: 1. Cement Mortar Lining: This lining consists of a layer of cement mortar applied to the interior surface of the pipe. It provides a smooth and durable barrier against corrosion and is commonly used in water and wastewater applications. 2. Polyethylene Encasement: Polyethylene encasement involves wrapping the pipe with a layer of polyethylene film. This lining provides excellent corrosion protection and is often used in aggressive soil conditions. 3. Polyurethane Lining: Polyurethane lining is a spray-applied material that forms a seamless and flexible barrier inside the pipe. It offers superior resistance to chemicals and abrasion, making it suitable for applications involving aggressive fluids. 4. Epoxy Lining: Epoxy lining is a popular choice for lining ductile iron pipes, as it provides excellent resistance to corrosion and chemicals. It is typically applied as a liquid coating that cures to form a smooth and protective layer. 5. Zinc Coating: Zinc coating, also known as galvanizing, involves applying a layer of zinc to the exterior surface of the pipe. This lining provides corrosion resistance and is commonly used in outdoor and exposed applications. These lining materials offer different advantages and are chosen based on the specific needs of the application. Factors such as the type of fluid being transported, environmental conditions, and expected service life are considered when selecting the most suitable lining material for ductile iron pipes.

- Q: Why is the cast iron tube lined with cement? Under what circumstances are ductile iron pipes lined with cement, and under what circumstances do not have to be lined with cement?

- The cement lining protects the water quality, reduces the head loss and improves the service life of the spheroidal graphite pipe. As long as the water delivery hose is used, the cement lining must be used. There is no lining cement for conveying air.

Send your message to us

Ductile Iron Pipe For Water Project On Sale From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords