Ductile Iron Manhole Cover with Competitive Price for Mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4300 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

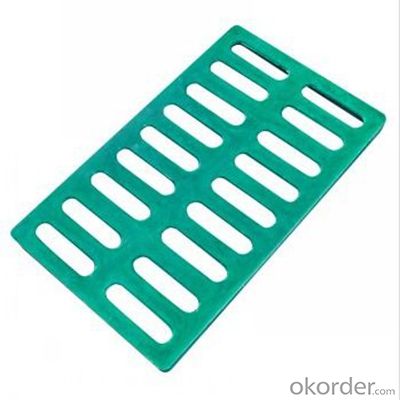

product name: ductile iron manhole cover

1. material: cast iron, ductile iron, malleable iron

2. duty: EN124 A15 B125 C250 D400 E600 F900

3. color: black green gray and etc.

4. design: we can provide OEM service, according your design to do moulds, surface and logo.

5. application: expressway, sidewalk, park, garden, municipal pipeline, telecommunication, water and electrical power projects.

Features

1.High Intensity

It adopts macromolecule complex material and reinforcing steel bar moulded by high temperature and press at one time.

2.Durable

Acid-alkali and corrosion resistance; anti-rust; insulation; weatherability; excellent anti-pressure capability.

3.Unique appearance

Rich colors;the cover is not sprayed in surface but painted in whole material so that the color can keep lasted

Pictures

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 30-45 days

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard.

FAQ

1.Q: Are you factory ?

YES! We are a professional ductile iron &gery iron casting Factory in China.

2.Q: How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.Q: Do you provide OEM Service?

Yes, we provide OEM Service.

4.Q: What 's your quotation element?

Drawing, material, weight and quantity.

- Q: What are the casting parts used to test shrinkage holes?

- 2. x ray. This method can do nondestructive testing, but the cost is higher. Generally, high castings are required.

- Q: The casting defects of pores, trachoma how to repair?

- Metal repair can be used to fill the repair. Airhole 2mm following LT102 recommend the use of liquid metal repairing agent.

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What's the density of the cast iron? The density is thin and the density is thin

- There is a hot knot in the thick area, which easily causes microscopic shrinkage and makes the casting not dense. A riser may be added for shrinkage relief.

- Q: What should I pay attention to when designing a casting structure?

- 1 of the casting in metal mold cooling was faster than sand, metal type and let, thus casting in metal mold casting, casting stress generated in the ratio of sand casting to crack tendency is also large, but also prone to misrun and cold lap, white (for casting casting). Defect. Usually: (1) in the prevention of metal casting casting crack aspect should pay attention to the following problems: the structure of A in wall thickness, wall transition and connection to the ease, corner fillet appropriate requirements such as should be more strict than sand casting; B should be connected vertically connected with the wall to tilt C; for the weak parts of the structure should be set to strengthen ribs, bosses, to prevent casting; D should minimize the obstacle free shrinkage of the boss, casting rib, flange and other prominent part; E in the casting arrangement of ribs, but also should consider its influence on the casting shrinkage.

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: Why should pig iron be used in casting?

- 1, in the absence of special requirements, the most important thing is that the price is cheap.2, pig iron castings quenching process requirements are not high. You can do it by hand.3, pig iron casting hardness is very large, can meet many requirements.4, pig iron castings, high temperature resistance is relatively strong. Like stoves are pig iron castings.5, pig iron casting plasticity is very bad, but in some experiments, but use this weakness to improve the sensitivity of the experiment.Wait

- Q: Shandong foundry, casting small pieces of precision casting

- Dongying Huayang precision casting factory, the smallest to do 2G pieces.

Send your message to us

Ductile Iron Manhole Cover with Competitive Price for Mining

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 set

- Supply Capability:

- 4300 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches