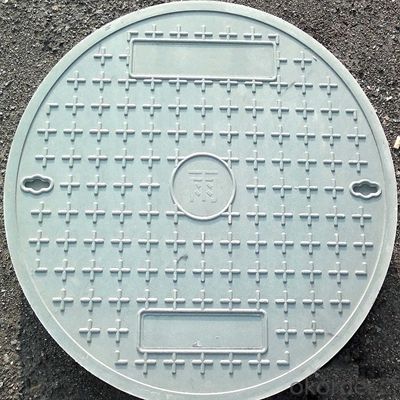

Ductile Iron Manhole Cover of Different Colour

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

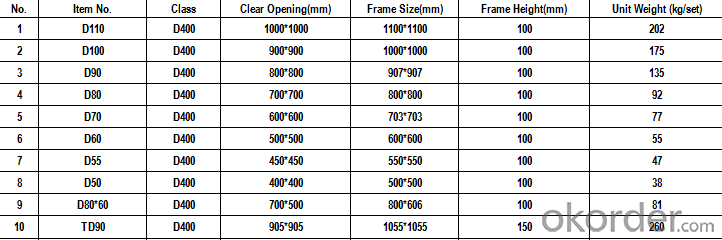

Specification

Product Description:

· Application: Construction,Industrial

· Material: Iron

· Dimensions: OEM

Features

Higher quality /higher tensile

Higher security /long life

Possibilities of new locking systems

Packaging & Shipping

· Packaging: Details Pallet with bubble film, Carton or with pallet,

· Delivery Detail: 30-45 days

About Us

· We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

· CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers. Our customer come from America, Morocco , saudi arabia, Iran , Algeria and so on.

Our Services

· 1. Sample is available for free.

· 2. OEM and ODM are welcome.

· 3. Free charge of design labels and cartons.

· 4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

· 5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

· 6. After the cooperation: Any of your problem will be solved within 24 hours.

Pictures:

FAQ

1.Q: Are you factory ?

YES! We are a professional ductile iron &gery iron casting Factory in China.

2.Q: How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.Q: Do you provide OEM Service?

Yes, we provide OEM Service.

4.Q: What 's your quotation element?

Drawing, material, weight and quantity.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: The casting sand is going on

- 3, prevention measures(1) to improve the strength of sand mold (core), especially surface strength, high temperature strength, refractoriness, compact, better coating, good core coating and parting surface coating.(2) mould and box can prevent damage;(3) the core should have clearance.

- Q: What are the casting parts tested?

- The surface brightness, appearance, size, chemical composition, weight, material, surface defects, internal defects, seals need to be checked, leakage, etc.

- Q: What kind of casting process is used for cast iron parts? And what are the cast steel parts adopted?

- The types and uses of foundry sand according to the mineral composition of different silica sand and non siliceous sand is divided into two categories. The main mineral composition of silica SiO2.: natural silica sand used for non-ferrous metal casting, cast iron and steel castings in small sand and core sand. The selection of natural silica sand: used in organic matter as the binder of various sand and core sand. The artificial sand for sand and core sand castings. Non siliceous sand and non siliceous sand have many kinds and different uses. Limestone sand: crushed by limestone, the main mineral composition is CaCO3, used for casting sand and core sand. Zirconium sand: the main mineral composition is ZrO2 SiO2, used for large steel castings and alloy steel pieces of core sand or sand surface sand, or powder used as coating. Magnesia: the main mineral composition is MGO, used for high manganese steel casting surface sand, core sand, and its powder can be used as coating. Chromite ore: the main mineral composition is chromite FeO. Cr2O3, used for large or special casting steel surface sand, core sand, its powder can be used as coating.

- Q: What are the casting parts processing engineering?

- At present, casting processing, according to metal classification, divided into cast iron, cast steel, casting non-ferrous metal.

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Uneven casting density is caused by uneven shrinkage of the casting during solidification.

- Q: How can the casting be quenched and tempered?

- Cast steel annealing or normalizing parts in strength and toughness is insufficient, can be used in quenching and tempering treatment. It is mainly used for gear, gear and other parts of the cast steel. The conditioning has two kinds: one kind is cast directly after quenching and tempering, with warm water (40---50 degrees) intermittent cooling, suitable for ZG270---500, ZG310----570 and other castings.

- Q: What is the casting material?

- Gray iron, carbon steel, low alloy steel, ductile iron, stainless steel, Aluminum Alloy can all be cast out

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine,

Send your message to us

Ductile Iron Manhole Cover of Different Colour

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches