Ductile Cast Iron Pipe ISO2531 / EN545 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 199 m

- Supply Capability:

- 9999 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

1) Pipes confirm to ISO2531,K9 class,T type joint,6m long,with inside cements lining conform to ISO4179, outside Zinc spraying(130g/m2) and bitumen coating(70μm) conform to ISO8179.

2) Pipe ends: Spigot and socket ends, with 100% SBR rubber gaskets

accoding to ISO4633

3) we can do third party inspection according to customer's request.

4) Our products have been sold to many international market,

such as Middle East and South East Asia and Africa.

2,Main Features of the Ductile Iron Pipe:

·High yield strength

·High tensile Strength

·High corrosion resistance

·Pressure Resistence

·Anti-corrosion

·Installation is convenient

·Satisfy the highest hygienic standards

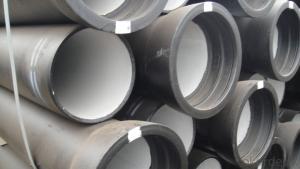

3,Ductile Iron Pipe Images:

4.FAQ:

We have organized several common questions for our clients,may help you sincerely:

Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q: Are ductile iron pipes resistant to acid mine drainage corrosion?

- Yes, ductile iron pipes are generally resistant to acid mine drainage corrosion. Their high durability, strength, and corrosion resistance make them suitable for transporting water in acidic environments, such as those affected by acid mine drainage.

- Q: How do ductile iron pipes handle ground movement in earthquake-prone areas?

- Ductile iron pipes are designed to withstand ground movement in earthquake-prone areas due to their inherent strength and flexibility. The ductile nature of the iron allows the pipes to deform and absorb the seismic energy without breaking or fracturing. This ensures their durability and ability to maintain water supply and drainage systems even during seismic events. Additionally, ductile iron pipes have superior joint integrity, which further enhances their resistance to ground movement and minimizes the risk of leaks or pipe failure.

- Q: Can ductile iron pipes be used for underground storage tanks?

- No, ductile iron pipes are not suitable for underground storage tanks. Underground storage tanks usually require special materials that have corrosion resistance and can withstand the pressure and environmental conditions.

- Q: Are ductile iron pipes suitable for acidic or alkaline environments?

- Yes, ductile iron pipes are suitable for both acidic and alkaline environments. They have excellent resistance to corrosion, making them a reliable choice for transporting fluids in a wide range of pH levels.

- Q: How are ductile iron pipes tested for hydrostatic pressure?

- Ductile iron pipes are commonly used for water and wastewater applications due to their strength and durability. To ensure the quality and reliability of these pipes, they undergo hydrostatic pressure testing. Hydrostatic pressure testing involves subjecting the ductile iron pipes to internal pressure higher than their normal operating pressure. This is done to assess their ability to withstand the maximum pressure they are expected to encounter during their service life. The testing process typically begins with the selection of a sample set of pipes from a production batch or shipment. These samples are carefully prepared by removing any surface coatings or debris that could affect the accuracy of the test results. Next, the prepared samples are placed within a specially designed test rig or test line. The test rig is equipped with all the necessary connections, valves, and gauges to control and monitor the test conditions accurately. Once the samples are secured in the test rig, water or another suitable test fluid is slowly introduced into the pipes. The pressure is then gradually increased to a predetermined level, typically exceeding the expected operating pressure by a certain factor. This elevated pressure is maintained for a specified duration, usually for several hours, to assess the pipes' structural integrity and leak resistance. During the test, the pipes are closely monitored for any signs of leakage, deformation, or failure. Skilled technicians or engineers observe the pressure gauges and visually inspect the pipes for any visible defects or abnormalities. Additionally, automated systems may be employed to continuously record and analyze the pressure readings, ensuring accurate data collection. After the specified test duration, the pressure is gradually released, and the pipes are carefully inspected for any permanent deformation or residual stress. This inspection may involve visual examination, dimensional measurements, or even non-destructive testing techniques such as ultrasonic testing or magnetic particle inspection. The test results are then evaluated against the relevant industry standards or specifications to determine the pipes' compliance with safety and performance requirements. If the pipes pass the hydrostatic pressure test, they are deemed suitable for their intended application. However, if any issues or failures are identified, further investigation, analysis, or corrective actions may be necessary before the pipes can be approved for use. Overall, hydrostatic pressure testing plays a crucial role in ensuring the quality and reliability of ductile iron pipes. By subjecting these pipes to rigorous testing procedures, manufacturers can provide customers with pipes that meet the highest standards of safety and performance.

- Q: Can the sealing ring of ductile iron pipe be reused?

- The sealing ring is hard to install and take off. I have been in this line for six years. I haven't seen it removed. The rubber ring itself is not expensive. It is not necessary to reuse it.

- Q: Can ductile iron pipes be used in areas with high soil acidity and alkalinity?

- Yes, ductile iron pipes can be used in areas with high soil acidity and alkalinity. Ductile iron is highly resistant to corrosion and can withstand extreme pH levels, making it suitable for such environments.

- Q: Can ductile iron pipes be used for stormwater management?

- Yes, ductile iron pipes can be used for stormwater management. Ductile iron is a strong and durable material that is resistant to corrosion and can withstand the high flow rates and pressures typically associated with stormwater management systems. These pipes have been widely used for various applications, including stormwater drainage and sewage systems. Their ability to handle heavy loads and withstand environmental factors makes them a suitable choice for stormwater management, ensuring efficient water flow and preventing flooding in urban areas. Moreover, ductile iron pipes have a long lifespan, reducing the need for frequent maintenance and replacement, making them a cost-effective choice for stormwater management infrastructure.

- Q: Can ductile iron pipes be used for irrigation of golf courses?

- Yes, ductile iron pipes can be used for irrigation of golf courses. Ductile iron pipes are known for their durability, strength, and resistance to corrosion, making them suitable for various applications, including irrigation systems. They can withstand high-pressure water flow and are less likely to crack or break compared to other materials. Additionally, ductile iron pipes have a longer lifespan, reducing the need for frequent maintenance or replacement. Therefore, they are a reliable choice for irrigating golf courses, where a consistent and efficient water supply is crucial for maintaining healthy turf and landscaping.

- Q: Are ductile iron pipes suitable for use in wastewater treatment plants?

- Ductile iron pipes are indeed a suitable option for utilization in wastewater treatment plants. This is due to the fact that ductile iron possesses immense strength and durability, enabling it to endure the harsh and corrosive environment commonly found in such facilities. Furthermore, it boasts exceptional resistance against abrasion, corrosion, and chemical assaults, rendering it a dependable choice for the conveyance of wastewater and the handling of diverse chemicals and substances encountered in the treatment process. Another advantage of ductile iron pipes lies in their high tensile strength, allowing them to withstand both high-pressure conditions and the weight of the surrounding soil. Moreover, these pipes are renowned for their flexibility, affording them protection against ground movement and settlement, thus ensuring long-lasting performance and dependability within wastewater treatment plants.

Send your message to us

Ductile Cast Iron Pipe ISO2531 / EN545 On Sale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 199 m

- Supply Capability:

- 9999 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords