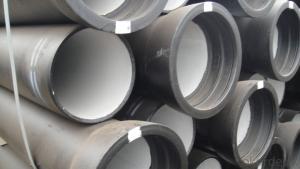

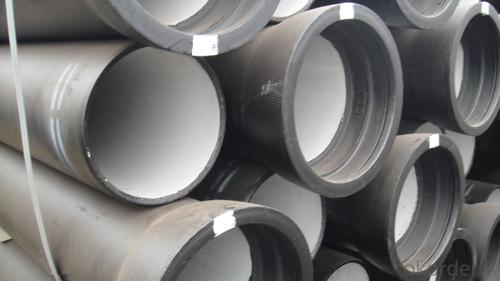

Ductile Iron Pipe K9 On Sale ISO2531/EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Place of Origin: China (Mainland)

Model Number: T type / K type / Flange type

Length: 6M/5.8M/Negotiable

Standard: ISO2531/EN545 for portable and EN598 for sewer lines

Application: Potable/Sewage Water

Diameter: DN80~DN1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: STANDARD

Pull Strength: 420 Yield (≥ MPa): 300

Material: Cast Iron

Type: Ductile Iron Pipes

Certification: ISO2531 and EN545

Specification: DN80~DN2600

Thickness: standard

Usage: water pipe Packaging & Delivery

Packing Details

Packaging Details: DN80~DN300 are bundled with steel belts, others are in bulk condition.

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

- Q: Are ductile iron pipes susceptible to external loading or pressure?

- Ductile iron pipes, just like any other material, are susceptible to external loading or pressure. They possess a certain level of strength and tolerance to endure external forces. However, excessive external loading or pressure can result in the deformation or failure of these pipes. To avoid any harm caused by external loading, it is crucial to ensure proper installation and support of ductile iron pipes. Furthermore, the design and engineering of the pipeline system should take into account the expected external loading and pressure to guarantee the pipes' effectiveness in handling the anticipated conditions. Regular inspections and maintenance play a vital role in detecting and resolving issues associated with external loading or pressure that may arise over time.

- Q: Can ductile iron pipes be used for bridge piers?

- Yes, ductile iron pipes can be used for bridge piers. Ductile iron pipes are known for their high strength and durability, making them suitable for various applications, including bridge construction. They have excellent resistance to corrosion and can withstand heavy loads, making them a reliable choice for supporting bridge piers. Additionally, ductile iron pipes offer ease of installation and maintenance, which can be advantageous in bridge construction projects. However, it is important to consider the specific requirements and design specifications of the bridge before selecting ductile iron pipes as the material for bridge piers. Proper engineering evaluation and consideration of factors such as load capacity, soil conditions, and environmental factors are essential to ensure the suitability and safety of using ductile iron pipes for bridge piers.

- Q: Can ductile iron pipes be used for underground oil and gas pipelines?

- Yes, ductile iron pipes can be used for underground oil and gas pipelines. Ductile iron is a strong and durable material that can withstand the high pressure and corrosive nature of oil and gas transportation. It has excellent tensile strength and impact resistance, making it suitable for underground applications. Ductile iron pipes are also resistant to external loads, which is important for underground pipelines that may be subject to soil movement or heavy traffic. Furthermore, ductile iron pipes can be easily jointed, allowing for efficient installation and maintenance. However, it is important to consider factors such as soil conditions, environmental factors, and specific project requirements before choosing ductile iron pipes for underground oil and gas pipelines.

- Q: Are ductile iron pipes resistant to abrasion?

- Yes, ductile iron pipes are highly resistant to abrasion.

- Q: Can ductile iron pipes be used for underground irrigation systems?

- Yes, ductile iron pipes can be used for underground irrigation systems. Ductile iron pipes are commonly used in various applications, including water supply and distribution systems. They are known for their strength, durability, and resistance to corrosion, making them suitable for underground installations. Additionally, ductile iron pipes have excellent pressure-bearing capacity and can withstand the high pressures often required for irrigation systems. However, it is important to ensure proper installation and maintenance to prevent any damage or leaks in the system.

- Q: What is the expected cyclic fatigue life of ductile iron pipes?

- Various factors such as material composition, pipe design, loading conditions, and environmental factors can affect the expected cyclic fatigue life of ductile iron pipes. However, ductile iron pipes are widely recognized for their exceptional ability to withstand fatigue. Ductile iron pipes are specifically engineered to endure cyclic loading, which is common in water distribution and sewer systems due to fluctuating pressures and vibrations. These pipes possess a unique microstructure that confers high strength and ductility, enabling them to resist crack formation and growth under cyclic loading. Numerous studies and industry standards have provided estimates for the expected cyclic fatigue life of ductile iron pipes. For instance, the American Water Works Association (AWWA) C151 standard recommends a design life of 100 years for ductile iron pipes used in water distribution systems, underscoring their long-term durability and resistance to fatigue. Furthermore, research studies have demonstrated that ductile iron pipes can withstand over 1 million cycles of loading without exhibiting any signs of fatigue failure. The fatigue strength of ductile iron pipes can be further augmented by employing protective coatings or linings to reduce the impact of corrosion and abrasion. Nevertheless, it is important to recognize that various factors, such as manufacturing quality, installation practices, and maintenance procedures, can influence the expected cyclic fatigue life of ductile iron pipes. Regular inspections, appropriate handling, and adherence to recommended installation guidelines can help ensure the longevity and performance of ductile iron pipes. In conclusion, while the expected cyclic fatigue life of ductile iron pipes can be subject to variation due to several factors, these pipes are generally renowned for their outstanding fatigue resistance and offer a dependable and enduring solution for water distribution and sewer systems.

- Q: Are ductile iron pipes suitable for bridge piers or abutments?

- Ductile iron pipes are indeed appropriate for bridge piers or abutments. This material, known for its strength and durability, is extensively utilized in diverse infrastructure undertakings, such as bridges. It possesses exceptional mechanical characteristics, including remarkable tensile strength and impact resistance, rendering it capable of withstanding substantial loads and external forces. Moreover, ductile iron pipes exhibit high resistance to corrosion and enjoy a lengthy service life, which is crucial for structures like bridge piers or abutments that face harsh environmental conditions. The adaptability and dependability of ductile iron pipes deem them a fitting choice for supporting and fortifying bridge structures, ensuring their safety and longevity.

- Q: What are the different types of thrust restraints for ductile iron pipe?

- There are several different types of thrust restraints that can be used for ductile iron pipe installations. These thrust restraints are designed to prevent the pipe from moving or separating under the forces generated by internal pressure, external loads, or changes in temperature. 1. Thrust blocks: Thrust blocks are concrete structures that are typically installed at bends, tees, and other changes in direction in the pipeline. They are designed to resist the thrust forces by transferring them to the surrounding soil or foundation. 2. Mechanical restraints: Mechanical restraints, such as tie rods or harnesses, are used to restrain the pipe by exerting an external force on it. These restraints are typically made of steel and can be adjusted to accommodate changes in pipe length or alignment. 3. Pipe anchors: Pipe anchors are devices that are installed at specific intervals along the pipeline to provide resistance against axial movement. They are usually made of steel and are embedded into the surrounding soil or concrete to provide a secure anchor point for the pipe. 4. Thrust collars: Thrust collars are devices that are installed around the pipe to prevent it from moving or separating. They are typically made of steel and are placed at strategic locations along the pipeline to absorb the thrust forces. 5. Restrained joint systems: Restrained joint systems are specialized pipe joints that are designed to resist axial forces. These joints typically have additional features, such as keyways or wedges, that provide resistance against movement. It is important to select the appropriate type of thrust restraint based on the specific requirements of the ductile iron pipe installation. Factors such as the pipe diameter, operating pressure, soil conditions, and potential external loads should be considered when determining the most suitable thrust restraint system. Consulting with a qualified engineer or pipe manufacturer can help ensure the proper selection and installation of thrust restraints for ductile iron pipe.

- Q: Ductile iron pipe, socket connection, pipe length, you can cut open it?

- Yes, but the pipe that needs cutting is a cut off pipe with a scissors mark.

- Q: Are ductile iron pipes compatible with other pipe materials?

- Generally, other pipe materials can be compatible with ductile iron pipes. The high level of flexibility and strength of ductile iron pipes allows for their connection with various materials like PVC, HDPE, and steel. Transition fittings are often utilized to securely and prevent leaks when connecting ductile iron pipes with other materials. To maintain the integrity of the pipeline system and ensure compatibility, it is crucial to follow industry standards and guidelines when joining different pipe materials.

Send your message to us

Ductile Iron Pipe K9 On Sale ISO2531/EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords