Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 10

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

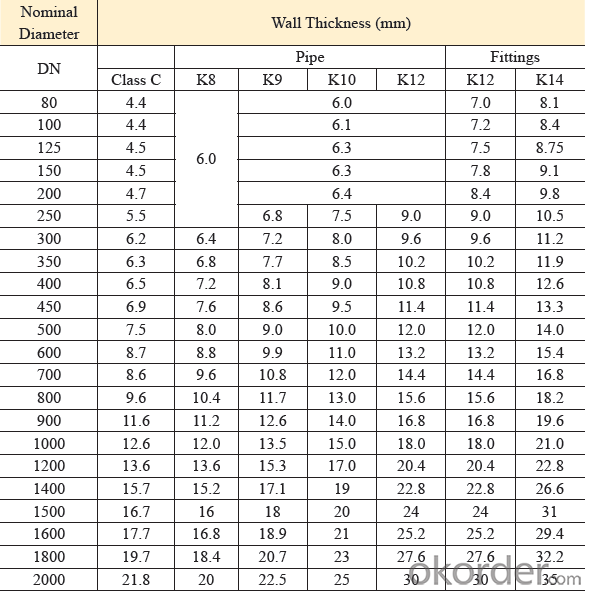

Specification:

1. size : DN80-DN2000 available with PN16 or PN10 or PN25 flanges

2.Standard : ISO2531/EN545/EN598/AWWA standard

3. WRAS Potable Water FBE Internal Lining

4.Material : Ductile iron

5.Technical: Casting

6. Type: Socket / flange PN10 / PN16 / PN25

7. Length=6m, 5.8m

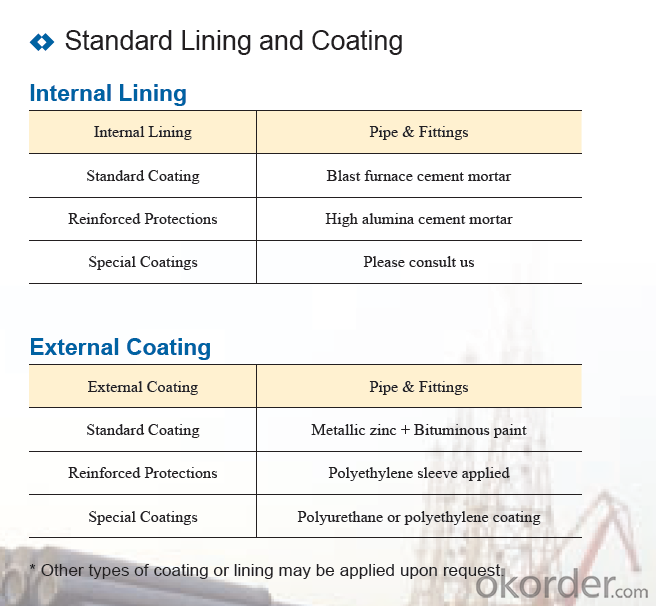

8. Coating: Fusion bonded epoxy to 300 microns Dry Film Thickness

Portland cement lining internally and zinc-rich paint with not less than 70 microns bitumen externally

Quality:

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

Standard Lining and Coating:

Transport:

- Q: Are ductile iron pipes suitable for landfill leachate collection?

- Yes, ductile iron pipes are suitable for landfill leachate collection. Ductile iron pipes have excellent strength and durability, making them capable of withstanding the harsh and corrosive nature of landfill leachate. Additionally, they have a long lifespan and are resistant to both external and internal corrosion, making them a reliable choice for this application.

- Q: The difference between ductile cast iron pipe and machine-made cast iron pipe

- Of different uses, ductile iron pipes are widely used for municipal water supply and drainage, rural drinking water and outdoor fire fighting works; mechanism cast iron pipes are mainly used in the city.

- Q: What is the minimum pipe diameter of cast iron pipe?

- Nominal diameter of continuous grey cast iron pipe is 75~1200 mm, minimum 75 mm, maximum 1200 mm.

- Q: What is the lifespan of ductile iron pipe?

- The lifespan of ductile iron pipe can vary depending on various factors such as the quality of the pipe, the environment in which it is installed, and the maintenance practices followed. However, on average, ductile iron pipe has a lifespan of around 80 to 100 years. This long lifespan can be attributed to the inherent durability and strength of ductile iron, which allows it to withstand high pressure, external loads, and environmental conditions. Additionally, ductile iron pipe is often coated with protective linings such as cement mortar or epoxy to further enhance its resistance to corrosion and extend its lifespan. Regular inspections and maintenance can also contribute to prolonging the lifespan of ductile iron pipe by identifying and addressing any potential issues in a timely manner. Ultimately, with proper installation, maintenance, and care, ductile iron pipe can provide reliable and long-lasting service for several decades.

- Q: How are ductile iron pipes protected against internal corrosion caused by chemicals?

- Ductile iron pipes are protected against internal corrosion caused by chemicals through a combination of several protective measures. Firstly, these pipes are usually lined with a cement mortar lining or an epoxy coating. This lining acts as a barrier between the chemical substances in the water or sewage and the iron material of the pipe, preventing direct contact and corrosion. In addition to the lining, a corrosion-resistant polymer or bituminous coating is often applied to the exterior of the ductile iron pipes. This coating serves as an extra layer of protection, safeguarding the pipe against any external chemical exposure that may occur. Furthermore, cathodic protection is commonly employed to prevent internal corrosion. This technique involves the use of sacrificial anodes, typically made of zinc or magnesium, which are attached to the pipe. The anodes corrode over time instead of the iron, effectively sacrificing themselves to protect the pipe from corrosion caused by chemicals. Regular maintenance and monitoring of the ductile iron pipes are also crucial in preventing and addressing any potential corrosion issues. This includes routine inspections, cleaning, and repairing any damaged or corroded areas promptly. Overall, the combination of lining, external coating, cathodic protection, and maintenance practices ensures that ductile iron pipes are well-protected against internal corrosion caused by chemicals, prolonging their lifespan and ensuring the integrity of the pipeline system.

- Q: How long does the cast iron pipe of indoor direct buried sewage need to be examined?

- UPVC, also called hard PVC, is an amorphous thermoplastic resin made by polymerization of vinyl chloride monomer, with certain additives (such as stabilizers, lubricants, fillers, etc.). In addition to additives, the method of blending with other resins is also applied to make it have obvious practical value. These resins are CPVC, PE, ABS, EVA, MBS and so on. UPVC has high melt viscosity and poor flowability. Even if the pressure and melt temperature are increased, the fluidity is not changed. In addition, the molding temperature of the resin is very close to the thermal decomposition temperature, and the molding temperature range is very narrow. It is a difficult material to be formed.

- Q: Can ductile iron pipe be used for oil and gas transmission pipelines?

- Ductile iron pipe is a suitable choice for oil and gas transmission pipelines due to its many advantageous properties. With its high tensile strength, it can withstand the pressures and stresses involved in this application. Moreover, ductile iron pipe exhibits excellent corrosion resistance, which is further improved by protective coatings on its exterior. In addition, its durability and longevity ensure the reliability of oil and gas transmission pipelines. Overall, ductile iron pipe offers a reliable and cost-effective solution for oil and gas transmission pipelines.

- Q: Can ductile iron pipes be used in contaminated soil conditions?

- Indeed, contaminated soil conditions pose no obstacle to the utilization of ductile iron pipes. Ductile iron boasts exceptional attributes such as robustness, endurance, and resistance to corrosion, rendering it appropriate for diverse soil conditions, even those tainted by chemicals or other harmful substances. The material's resistance to corrosion guarantees the pipes' ability to endure the adverse conditions and sustain their structural integrity throughout time. Nevertheless, it is crucial to take into account the nature and extent of soil contamination and seek guidance from specialists to ascertain whether supplementary protective measures or coatings are necessary to ensure the pipes' enduring efficiency.

- Q: Are ductile iron pipes compatible with other pipe materials?

- Yes, ductile iron pipes are compatible with other pipe materials. They can be connected to pipes made of various materials such as PVC, HDPE, steel, and more, using appropriate fittings and connectors.

- Q: What is the expected corrosion rate of ductile iron pipes?

- The expected corrosion rate of ductile iron pipes can vary depending on several factors, including the specific environment in which the pipes are installed, the pH and composition of the water or soil they come into contact with, and the presence of any corrosive substances or chemicals. In general, ductile iron pipes are known for their excellent resistance to corrosion compared to other materials such as cast iron or steel. This is due to the presence of a protective layer called a passive film, which forms naturally on the surface of the pipes when exposed to oxygen in the environment. This passive film acts as a barrier, preventing further corrosion from occurring. However, it is important to note that even ductile iron pipes can experience some level of corrosion over time, especially in aggressive or highly corrosive environments. The expected corrosion rate can range from very low to moderate, depending on the aforementioned factors. To ensure the longevity and performance of ductile iron pipes, it is recommended to implement proper maintenance and monitoring practices. This includes regular inspections, cleaning, and the application of protective coatings or linings when necessary. Additionally, implementing a cathodic protection system can further enhance the corrosion resistance of the pipes. Ultimately, it is important to consult with experts and professionals in the field of corrosion and pipe materials to accurately determine the expected corrosion rate of ductile iron pipes in a specific application or environment.

Send your message to us

Duct Iron Pipe DI Pipe ISO 2531 DN 80-2000mm PN 10

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords