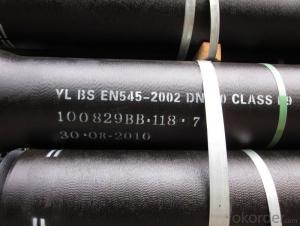

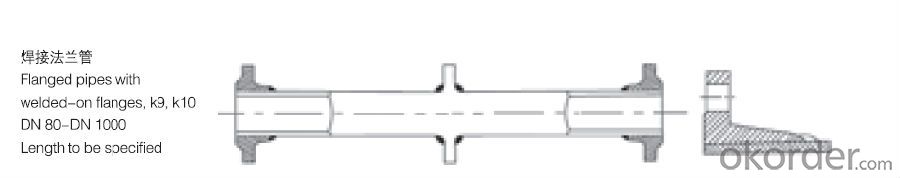

Duct Iron Pipe DI Pipe Flange Pipe with Welded ISO 2531 EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ductile iron pipe fittings:

1.Ductile iron fitting

2.EN545/ISO2531

3.Epoxy Internal and external

1), Product Information

Ductile Cast Iron Pipe Fitting & coupling manufactured by Xinxing Pipe Fittings Co., Ltd is mainly used for transferring the drinkable water and acid. With special ductile iron material, this series of pipe fittings can also be used for transferring the acid in the acid plant or transferring slurry. Xinxing Pipe Fittings Co., Ltd has been supplying Pipe Fittings for over 10 years and Pipe Fitting surface shall be smooth and free from sand holes, blow holes, distortion or any other defects. Hundreds of patterns are ready and Max. dia. is 1.2 meters with max. height of 2 meters.

2), Material

* Ductile Iron

3), Process

* Automatics machine lines

* Resin Sand

* Molding Boards

* Green Sand with hand molding

4), Inscription Style

* XinXing Foundry

* As per customers' requests

* Standard Inscription

5), Packing

* Plywood pallet

* Steel pallet

* As per customers' requirements

6), Inspection

* Foundry in-house

* Third Party inspection available upon request

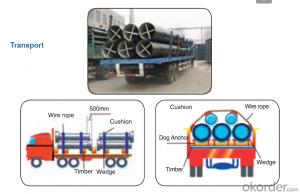

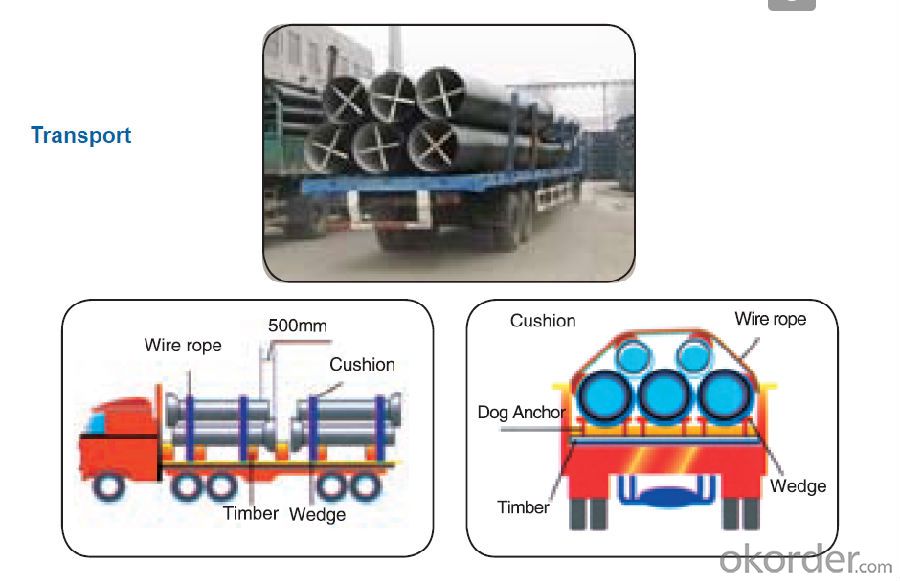

Transport:

- Q: Why is the sound speed of nodular cast iron lowered after heat treatment?

- After the heat treatment, the microstructure of the material changes, the graphite changes, eliminating the internal stress of molecules, thus slowing down the speed.

- Q: Can ductile iron pipes be used for bridge piers?

- Yes, ductile iron pipes can be used for bridge piers. Ductile iron pipes are known for their high strength and durability, making them suitable for various applications, including bridge construction. They have excellent resistance to corrosion and can withstand heavy loads, making them a reliable choice for supporting bridge piers. Additionally, ductile iron pipes offer ease of installation and maintenance, which can be advantageous in bridge construction projects. However, it is important to consider the specific requirements and design specifications of the bridge before selecting ductile iron pipes as the material for bridge piers. Proper engineering evaluation and consideration of factors such as load capacity, soil conditions, and environmental factors are essential to ensure the suitability and safety of using ductile iron pipes for bridge piers.

- Q: Can ductile iron pipe be used for industrial wastewater applications?

- Certainly, industrial wastewater applications can make use of ductile iron pipe. Renowned for its robustness, longevity, and corrosion resistance, ductile iron pipe proves itself suitable for a multitude of purposes, including wastewater systems. Its ability to withstand high pressure and endure demanding conditions renders it perfect for industrial wastewater applications that may involve abrasive or corrosive substances. Furthermore, the installation and maintenance of ductile iron pipe are effortless, resulting in reduced costs and guaranteed long-term dependability. Nevertheless, it remains crucial to carefully scrutinize the unique prerequisites of the wastewater application and seek guidance from professionals to ascertain the most fitting pipe material and design.

- Q: What are the requirements for the hydrostatic test of ductile iron pipes?

- The hydraulic pressure test shall be carried out in the backfill before trying to allow the pressure after passing the backfill, backfill, the graded gravel fill to 300mm above the top of pipe, and then the soil backfill, backfill process by 200~300 tamped pipeline above 500mm within more than 500 can be used in artificial ramming, mechanical compaction. The degree of compaction shall not be less than 0.93.

- Q: How does ductile iron pipe perform in areas with high groundwater levels?

- Ductile iron pipe proves to be highly effective in areas characterized by elevated groundwater levels. A notable advantage of this type of pipe lies in its resistance to corrosion, rendering it particularly suitable for underground applications and areas with high water tables. Unlike alternative materials, ductile iron pipe remains impervious to rust or corrosion caused by groundwater, ensuring its longevity and durability. Moreover, ductile iron pipe is distinguished by its exceptional strength and flexibility, enabling it to withstand the external pressure exerted by high groundwater levels. It effectively resists the buoyant forces exerted by water, thereby preventing any displacement or flotation. Furthermore, the joints of ductile iron pipe are tightly sealed, thus preventing any infiltration of groundwater into the pipe system. This guarantees the absence of leaks or water supply contamination, which is of utmost importance in areas with high groundwater levels. All in all, ductile iron pipe emerges as the optimal choice for areas with high groundwater levels due to its corrosion resistance, strength, and ability to maintain a secure and tightly sealed system. It provides a dependable and long-lasting solution for water distribution and sewer systems, even in challenging environments.

- Q: Can ductile iron pipes be used for underground compressed air systems?

- Underground compressed air systems can utilize ductile iron pipes due to their high strength and durability. These pipes are suitable for various applications, including underground installations, thanks to their corrosion resistance. This is especially important in underground systems where moisture and other environmental factors can cause damage over time. Moreover, ductile iron pipes have the capability to withstand high pressure, making them a dependable choice for compressed air systems. However, it is crucial to ensure proper installation of the pipes, including adequate support and protection, to prevent any damage or leaks. To maintain the longevity and efficiency of the underground compressed air system, regular maintenance and inspection should also be carried out.

- Q: Are ductile iron pipes suitable for wastewater systems?

- Indeed, wastewater systems can utilize ductile iron pipes. Ductile iron, renowned for its robustness and durability, exhibits resistance against corrosion and can endure the arduous conditions typically encountered in wastewater systems. Its exceptional tensile strength enables it to withstand the pressure and stress resulting from the movement of wastewater. Furthermore, the installation of ductile iron pipes is effortless, and their longevity ensures a cost-effective solution for wastewater systems. In conclusion, ductile iron pipes represent a dependable and appropriate choice for transporting wastewater in diverse applications.

- Q: How do we handle the leaking of the ductile iron pipe?

- A hoop is a component that holds or ties another material with one material. It belongs to the fastener. The hoop holding device is composed of a hoop plate, a wing plate, a tension tie plate, a bolt and an inner liner. There are many kinds of hoop, hoop cable, wire rod hoop, hoop cable, wire hoop, stainless steel hoop are commonly used.

- Q: What is the average weight of ductile iron pipe?

- The average weight of ductile iron pipe varies depending on the size and thickness of the pipe. However, on average, ductile iron pipes can weigh between 300 to 600 pounds per linear foot.

- Q: How is ductile iron pipe different from other types of pipes?

- Ductile iron pipe is different from other types of pipes primarily due to its superior strength and durability. Unlike traditional cast iron pipes, which are more brittle and prone to cracking, ductile iron pipes are highly resistant to impact and can withstand higher pressure. Additionally, ductile iron pipes have the advantage of being more flexible and easier to install, making them a preferred choice for various applications such as water and sewage systems.

Send your message to us

Duct Iron Pipe DI Pipe Flange Pipe with Welded ISO 2531 EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords