Duct Iron Pipe DI Pipe Flange Pipe with Cast ISO 2531 EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ductile iron pipe fittings:

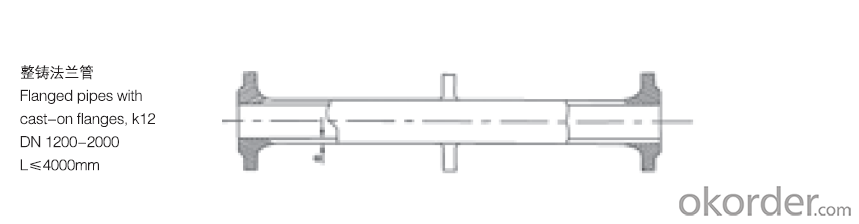

Dimensions standard:

ISO2531: 50-1000mm, PN10/16

BS4772: 50-1000mm, PN10/16

EN545: 50-1000mm, PN10/16

Connecting mode:

Flanged

Socketed

Mechanical connection

Loose flanged

Coatings:

Inner lined with cement and outside coated with zinc plus bitumen

Inner and outside coated with epoxy resin

Inner and outside coated with fusion bonded epoxy resin

Quality:

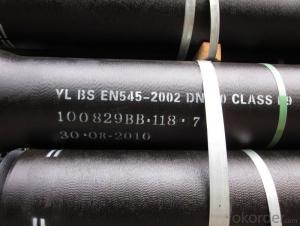

ISO 2531 or EN 545 Standard K9 Class, K12 Class

1. ISO 9001 Certificate

2. ISO 2531 & EN 545 Certificate

3. WRAS Potable Water Certificate for FBE Internal Lining

4. WRAS EPDM Rubber Gasket or NBR Rubber Gasket

5. DN80mm - DN2000mm

6. Black Bitumen or Blue FBE / Epoxy Coating

7. Lengh = 6m or cut into 5.6m, 5.7m, 5.8m

8. Client's Brand Customization Allowable

9. Container or Bulk Loading / Shipping

10.Delivery within one Month or According to Client's Order Quantity

11. Support Client or The Third Party Inspection before Shipment

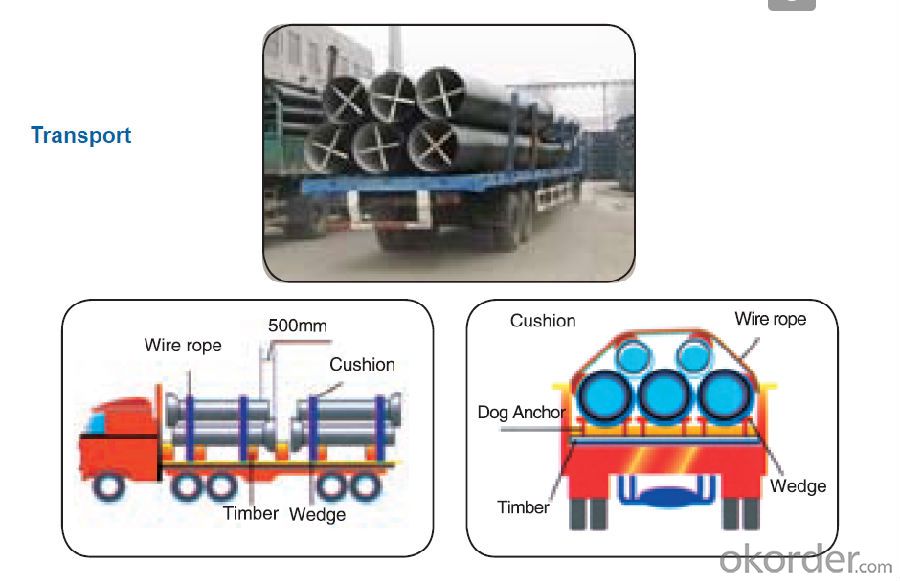

Transport:

- Q: What are the differences between ductile cast iron pipes and centrifugal ductile iron pipes?

- Centrifugal casting is a casting method. Ball milling cast iron pipe is a kind of material.

- Q: Can ductile iron pipe be used for pressure sewer systems?

- Yes, ductile iron pipe can be used for pressure sewer systems. Ductile iron pipe is known for its strength, durability, and resistance to corrosion, making it a suitable choice for various applications, including pressure sewer systems. It can withstand high pressure and provide a reliable conduit for transporting wastewater under pressure. Additionally, ductile iron pipe has excellent joint integrity, which ensures leak-free connections and minimizes the risk of sewer system failures. Therefore, ductile iron pipe is commonly used in pressure sewer systems due to its structural integrity and long lifespan.

- Q: Do ductile iron pipes require special handling during transportation?

- Yes, ductile iron pipes do require special handling during transportation. They are heavy and brittle, so they need to be loaded and unloaded carefully to prevent damage. Additionally, they should be properly secured and supported to avoid any bending or distortion during transit.

- Q: The difference between HDPE pipe and ductile iron pipe

- Different appearance, ductile iron pipe single length of 6 meters, large wall thickness; mechanism cast iron pipe single length of 3 meters, the wall thickness is thin.

- Q: How do ductile iron pipes handle ground movement in earthquake-prone areas?

- Ductile iron pipes are designed to withstand ground movement in earthquake-prone areas due to their inherent strength and flexibility. The ductile nature of the iron allows the pipes to deform and absorb the seismic energy without breaking or fracturing. This ensures their durability and ability to maintain water supply and drainage systems even during seismic events. Additionally, ductile iron pipes have superior joint integrity, which further enhances their resistance to ground movement and minimizes the risk of leaks or pipe failure.

- Q: How are leaks repaired in ductile iron pipe?

- Leak repairs in ductile iron pipes vary depending on the severity and location of the leak. One technique commonly used involves the application of epoxy-based sealants or leak repair clamps. For small leaks, epoxy sealants are commonly utilized. A specialized epoxy compound is applied to the leaking area, which then hardens and forms a durable seal. The epoxy is carefully spread on the pipe's surface, covering the leak and any surrounding damage. This method effectively addresses small leaks and offers a long-lasting solution. In cases where the leak is larger or more severe, leak repair clamps are often utilized. These clamps secure tightly around the pipe using rubber gaskets and bolts to provide a mechanical seal. The clamp's pressure compresses the gasket onto the pipe, creating a watertight seal and preventing further leakage. Leak repair clamps come in various sizes to accommodate different pipe diameters. Proper preparation of the pipe surface is crucial before applying either repair method. The area around the leak must be thoroughly cleaned and dried to ensure good adhesion of the epoxy or proper sealing with the clamp. It is also essential to adhere to the manufacturer's instructions and guidelines for the chosen repair method to achieve a successful and long-lasting repair. It is important to note that these repair methods are temporary solutions and may not be suitable for all situations. In cases of extensive pipe damage or aging infrastructure, it may be necessary to replace the affected pipe section entirely. It is recommended to seek professional assessment and guidance from qualified technicians or plumbers when dealing with leaks in ductile iron pipes. This ensures proper repairs and minimizes the risk of future issues.

- Q: How to correctly measure ductile iron pipe

- Ductile pipe diameter is around the tube around the peripheral measurement, use tools to gauge the inner diameter of the pipe, the length of the pipe is used to measure the ruler or tape, ductile iron pipe wall thickness can be measured directly, may also be a suitable tool for indirect measurement, the general profession will experience with project measure tube the size.

- Q: Do ductile iron pipes require external coatings or wraps?

- Ductile iron pipes typically require external coatings or wraps to protect against corrosion. Despite being strong and durable, ductile iron is still prone to corrosion when exposed to specific environmental conditions. Applying external coatings or wraps adds an extra layer of protection, extending the lifespan and maintaining the structural integrity of the pipes. These coatings can vary and may consist of materials like epoxy, polyethylene, or zinc, acting as a barrier between the pipe surface and corrosive elements in the environment. Additionally, wraps made of materials such as polyethylene or polypropylene can provide mechanical protection against impact or abrasion. Therefore, it is generally advisable to apply external coatings or wraps to ductile iron pipes to enhance corrosion resistance and ensure long-term performance.

- Q: Are ductile iron pipes suitable for industrial applications?

- Ductile iron pipes are highly suitable for industrial applications, given their exceptional mechanical properties and durability. This material is strong and sturdy, making it ideal for high-pressure and heavy-duty tasks. These pipes possess a high tensile strength, enabling them to withstand extreme conditions like high temperatures and corrosive environments. Moreover, ductile iron pipes exhibit superior resistance to cracking and fracturing, resulting in a longer lifespan and reduced maintenance costs. They can also handle external loads effectively, making them perfect for underground installations and industrial settings where heavy loads or vibrations may be present. Furthermore, these pipes offer excellent flow characteristics due to their smooth interior surface, ensuring efficient fluid transportation in industrial systems. Their resistance to wear and abrasion guarantees a consistent flow rate over time. Additionally, ductile iron pipes are versatile and can be utilized in various industrial applications, including water supply, wastewater treatment, industrial processes, and mining operations. They are available in a wide range of sizes to meet different requirements and can be easily connected using various jointing methods. In conclusion, ductile iron pipes provide the reliability, strength, and longevity required for industrial applications, making them an ideal choice for industries where durability and performance are essential.

- Q: Can ductile iron pipes be used for fire protection systems?

- Fire protection systems can utilize ductile iron pipes. Ductile iron, a form of cast iron, possesses both strength and flexibility, making it suitable for various applications, including fire protection systems. It boasts excellent mechanical properties, such as high tensile strength and impact resistance, which are essential for withstanding the pressures and stresses that can arise during fire suppression efforts. Ductile iron pipes are renowned for their durability and long lifespan, which is crucial for reliable and functional fire protection systems. They have a longer lifespan compared to materials like PVC or galvanized steel and are less susceptible to corrosion. This is particularly important for fire protection systems, as they must remain operational even after extended periods of inactivity. Additionally, ductile iron pipes exhibit exceptional fire resistance. They can withstand high temperatures without compromising their structural integrity, ensuring the fire protection system remains intact and functional during fire emergencies. This is pivotal for ensuring the safety of occupants and minimizing property damage. Furthermore, ductile iron pipes are compatible with a wide range of fittings, valves, and accessories commonly used in fire protection systems. This facilitates easy installation and integration into existing fire suppression networks. In conclusion, ductile iron pipes are a reliable and suitable choice for fire protection systems due to their strength, durability, fire resistance, and compatibility with other system components.

Send your message to us

Duct Iron Pipe DI Pipe Flange Pipe with Cast ISO 2531 EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords