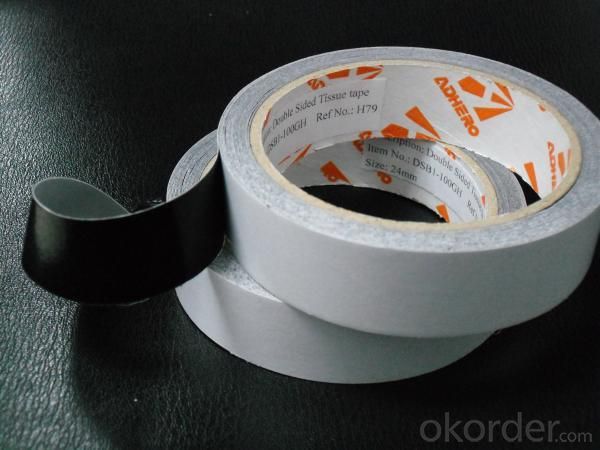

Easily Removable Double Sided Tissue Tape DS3-90H

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- Ten Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Double Sided Tissue Tape DS3-90H

1. Applications:

Courier envelope sealing, flying splice operations on papers and cardboard, leather and fabric bonding and positioning in shoe and baggage industry, sheet fixing and bonding in toy industry, stationery, advertisement, computer embroidery, packaging and foam laminating.

2. The products should be stored at room temperature and be kept away wet and/or heat source.

3. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

4. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

5. Special requirements will be satisfied after communications.

Technical Data of Double Sided Tissue Tape DS3-90H

CONSTRUCTION:

Carrier: Tissue paper

Adhesive: Solvent based acrylic

Liner: Silicone release PE-coated paper, white colour.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + tissue): 90 ± 5 micron

Initial Tack (14# steel ball): ≤ 100mm

Peel Adhesion (Kg/25mm): 1.7 ± 0.2Kg

Holding power: ≥ 150 min

PACKING of Double Sided Tissue Tape DS3-90H

Core I.D.: 3” (76mm±1)

Jumbo Roll:1.02 x 1000m; 1.24 x 1000m

Packaging:Wrapped with corrugated cardboard.

Cut Roll: roll width 3mm up

Remarks of Double Sided Tissue Tape DS3-90H

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: The door frame is glued on both sides of the curtain. Now the curtain doesn't work. It can't be cleaned on both sides. How can it be removed? But it doesn't break the paint on the door It's a little bit on the wall, too.

- It can be removed quickly with medical alcohol. Steps are as follows:1, ready medical alcohol, cotton swabs and dry cloth, medical alcohol and cotton swabs, pharmacies have to sell, the family needs spare things.

- Q: What are tapes and hot melt tapes?

- 1, the definition of duct tape tape to textile fiber cloth as the substrate. Coated with high viscosity synthetic glue, has a strong peeling force, tensile resistance, oil resistance, aging resistance, temperature resistance, waterproof, corrosion resistance, is a relatively high adhesive tape.

- Q: Will the double faced adhesive damage the wall?

- The main idea is to see what your wall is made of, if it is a metal paint, then what glue does not matter, and if it is latex paint, ordinary double-sided adhesive can be

- Q: Double sided adhesive tape for flexographic printing machines

- Mount tape is a double-sided tape, play a major role in two: first, flexo plate fixed on the printing roller or the sleeve, to prevent the printing plate in the printing process to tilt or displacement, ensure the normal printing process; two, through the selection of foam tape core density, to achieve fine control over in graphic design with the printing pressure, printing plate, improve the printing effect.

- Q: How do you clean the tape on top of your notebook?

- Two: use nail polish to remove the water to see, but because the water is likely to make the original color of the wall also fell off, so it is recommended to try in a less obvious small place firstThree: take a piece of vinegar coated dry cloth to cover the entire double-sided glue mark place, and until the double-sided adhesive after soaking wet, you can easily remove with a ruler

- Q: Coating process of organic silicon high temperature double faced adhesive tape. The substrate is PI or PET film.

- My company has done this thing, remember it is not PET, PI is not sure.

- Q: What are the 3M double-sided adhesive?

- 3M double-sided adhesive classification1, according to the characteristics are divided into double-sided adhesive, single-sided adhesive;2, according to the substrate points:Non-woven fabric substrate double adhesive (made of non-woven fabric substrate, double coated with acrylic rubber): such as 3M9448, 3M9080, 3M9075 and so on;

- Q: What kind of double faced glue is used at the bottom of the glass panel and the glass panel? How do you glue it?

- Most of the sides between glass panel and cooker bottom are ordinary double faced adhesive tape, but the width, thickness and color match are more coordinated. When bonding, the adhesive tape is glued to the upper edge of the shell, and then the panel is gently covered. It is possible to compress the screws around the head of the furnace before it is fixed in place.

- Q: Our products are: epoxy resin paste in a stone covered with oily double-sided adhesive on a piece of paper is now seeking a double-sided adhesive viscosity usually general once heated or after processing high viscosity glue or waterproof solid can be bent double surface adhesive heat Sol can be replaced with paper printing cloth for double-sided glue for I called 6 glue edge die without affecting the effect of have a heart

- You can use this one HY-T119 glue to adhesive bonding, before curing is not sticky, after curing has good strength, good toughness and bending, how how to fall is not out of the key is non-toxic glue, colorless and tasteless, environmental protection and easy to use

- Q: How is double faced adhesive made?

- They are widely used in leather, nameplate, stationery, electronics, automobile decoration, shoes, paper making, handicrafts, paste, positioning and so on. Hot melt double-sided adhesive mainly used in stickers, stationery, office and so on. Oily double sided adhesive used mainly

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2008 |

| Annual Output Value | US$ 2 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai, Port |

| Export Percentage | 35% - 50% |

| No.of Employees in Trade Department | 11-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10000 M2 |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Easily Removable Double Sided Tissue Tape DS3-90H

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- Ten Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches