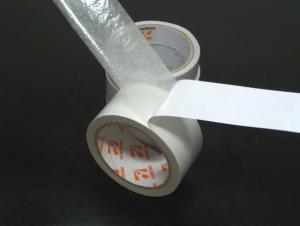

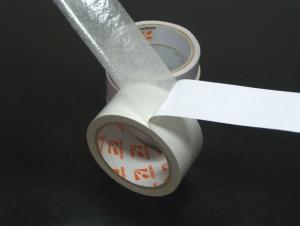

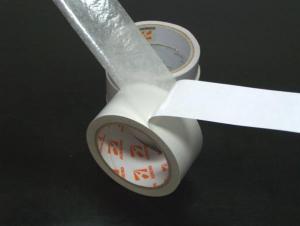

Double Sided Tissue Tape DS2-110H - Double Sided Tape at Walmart

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- Ten Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Double Sided Tissue Tape DS2-110H

1. Applications:

Courier envelope sealing, flying splice operations on papers and cardboard, leather and fabric bonding and positioning in shoe and baggage industry, sheet fixing and bonding in toy industry, stationery, advertisement, computer embroidery, packaging and foam laminating.

2. The products should be stored at room temperature and be kept away wet and/or heat source.

3. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

4. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

5. Special requirements will be satisfied after communications.

Technical Data of Double Sided Tissue Tape DS2-110H

CONSTRUCTION:

Carrier: Tissue paper

Adhesive: Solvent based acrylic

Liner: Silicone release PE-coated paper, white colour.

TYPICAL PHYSICAL PROPERTIES:

Total Thickness (adhesives + tissue): 110 ± 5 micron

Initial Tack (14# steel ball): ≤ 100mm

Peel Adhesion (Kg/25mm): 2.0 ± 0.2Kg

Holding power: ≥ 200 min

PACKING:

Core I.D.: 3” (76mm±1)

Jumbo Roll:1.02 x 1000m; 1.24 x 1000m

Packaging:Wrapped with corrugated cardboard.

Cut Roll: roll width 3mm up

Remarks of Double Sided Tissue Tape DS2-110H

The data above are typical results and subject to change without notice.

Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

The products should be stored at room temperature and be kept away wet and/or heat source.

It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

- Q: The foam on the wall will not tear off the double foamIt is convenient to ask for a rib

- 4, you can try a rubber. But in the beginning may feel more and more dirty, but rub a little longer, you will see the effect, this method is relatively tired, have perseverance.5, with blisters, put a little detergent, and then brush with an old toothbrush just fine.6, with a cloth with alcohol or Erguotou wipe.7, with a letter of sodium and water a wipe off, or can also use paint thinner.

- Q: Cement floor floor leather with thick or thin double-sided adhesive

- Usually carpet affixed with thin mesh adhesive tape, if a short time to paste, it is recommended to use "Shanghai Yu Guang 9447R double-sided adhesive tape" removed,

- Q: How do you remove the double adhesive tape on the towel? Sticky very tight ~ ~ how to do?

- 1, with eraser along the edge of a little to rub inside, easy to trace. But depending on how sticky you are, it may vary in time. If conditions permit, the alcohol + eraser works very well2, you can take a piece of vinegar coated dry cloth to cover the entire double-sided glue mark place, and until the double-sided adhesive after soaking wet, you can easily remove with a ruler.

- Q: What's the material of PE foam double release tape? Urgently!!

- PE foam double-sided tape from the paper can be made of wood pulp, kraft paper, and recycled kraft paper as raw paper, are all available, or need to be monitored to see, you know what the material?

- Q: How do you remove the foam glue on the wooden floor?

- 1, with a hair dryer to the double-sided adhesive residual floor, blow a pass, to be weak after heating double-sided adhesive can be torn out, gently.2, anhydrous alcohol rub division, if the home has anhydrous alcohol, you can find cotton balls dipped in some anhydrous alcohol, to erase traces of double-sided adhesive. If there is no absolute alcohol, the white oil at home can also be replaced.

- Q: I would like to ask Heroes: I would like to register trademarks, double-sided tape, sealing tape and other tape products, which is the largest class of that kind of trademark?

- Landlord Hello, I have to help you find it.Sixteenth types of paper, paper products and office supplies

- Q: Coating process of organic silicon high temperature double faced adhesive tape. The substrate is PI or PET film.

- My company has done this thing, remember it is not PET, PI is not sure.

- Q: What are the main types of tape?

- According to the substrate division can be divided into:BOPP tape, cloth tape, kraft paper tape, masking tape, fiber tape,PVC tape, PE foam tape, etc..

- Q: What are the business scope of belt conveyor?

- FLEX TAPE super waterproof tape, not afraid of water, can be used in underwater operation, wide application, applicable materials include PVC, acrylic, metal,

- Q: I'd like to know the kind of tape

- Industrial tape: tape rubber floor electrical tape protective film adhesive sponge textured plastic green rubber knife free cut finger Mara tape, high temperature masking tape spray tin red masking tape wrapping film

1. Manufacturer Overview

| Location | Shanghai, China |

| Year Established | 2008 |

| Annual Output Value | US$ 2 Million |

| Main Markets | 20.00% North America 20.00% South America 10.00% Eastern Europe 10.00% Southeast Asia 10.00% Northern Europe 10.00% South Asia 10.00% Western Europe 5.00% Africa 5.00% Mid East |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai, Port |

| Export Percentage | 35% - 50% |

| No.of Employees in Trade Department | 11-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10000 M2 |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Double Sided Tissue Tape DS2-110H - Double Sided Tape at Walmart

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- USD3000 roll

- Supply Capability:

- Ten Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches