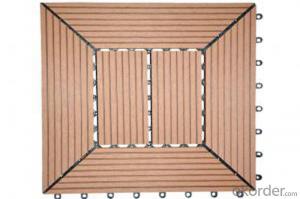

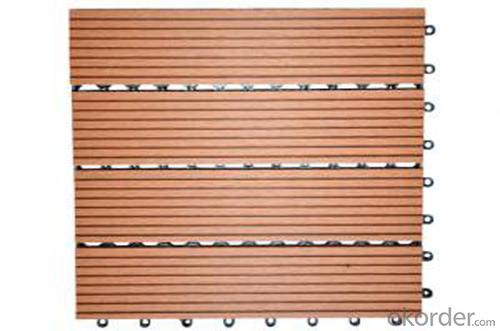

DIY Morden Anti-Skidding WPC Outside Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of DIY Morden Anti-Skidding WPC:

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

Composition of DIY Morden Anti-Skidding WPC:

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of DIY Morden Anti-Skidding WPC:

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

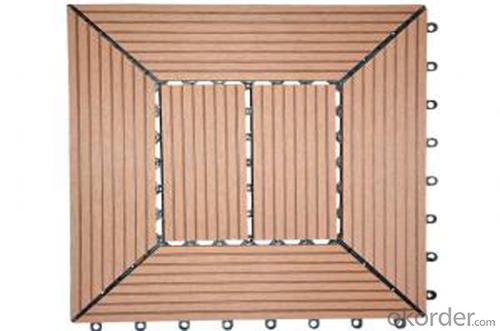

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

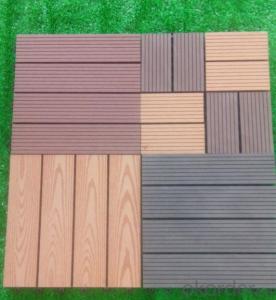

· Available in various colors

· Can be used in Temperature: -40 to +60°C

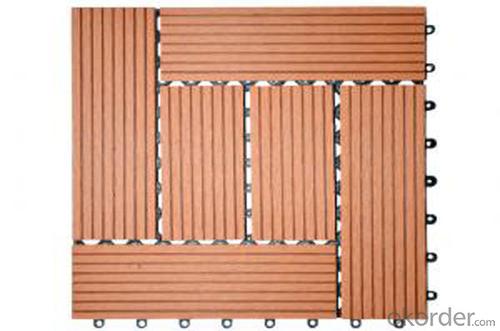

Installation of DIY Morden Anti-Skidding WPC:

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of DIY Morden Anti-Skidding WPC:

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- No, because the formaldehyde volatilization is slightly less than the density of gas, air, volatile gas, have good air tightness of floor leather or plastic material, the gas will be volatile and will be hampered by spreading to other direction can be volatile, after all, floor leather and plastic is not closed, on the floor on the floor or other plastic material will have a certain gap, but the floor leather and plastic can be obviously reduced formaldehyde volatilization.

- Q: That is, after the lime on the ground after the laying of plastic sheeting and then spread the concrete above the floor tiles on the floor so good? Do not put it or put it (plastic cloth)

- First, the purchase is the key to how to choose some of the moisture resistance of the ceramic tile, is the key to continue to enjoy the dry life in winter, there are six criteria for everyone to choose. The first: low water absorption rate of this tile usually have good moisture resistance, when buying, we can crack is tile surface observation, other glaze layer thick ceramic tile will also increase the moisture resistance of ceramic tile to a certain extent. Therefore, the user in the selection of ceramic tiles to watch the special table when the water content, water content less, good moisture-proof tiles, of course, the price is also high

- Q: Thick floor leather household PVC floor paper waterproof plastic carpet anti-skid plastic floor glue how to install

- The material is of high wear-resistant floor rubber products, the main types of floor glue is too much, please choose the site of special products, if you are a family choose stone plastic sheet, choose the mall commercial airport pure material, rubber flooring, floor board special dance dance, rubber floor has a high requirement for the quality of the ground, the ground should be flat. No sand, dry ground, ground cracks, no different use requirements, main floor glue fire, anti-skid, environmental protection, easy to clean, variety, fast construction, long service life, our factory production of the special plastic Mio dance floor, if so we can provide samples for reference, to the membrane of different thickness different price you want, our dance floor (dance floor, many kinds of special).

- Q: Is the plastic paper between the wood floor and the closet

- Wardrobe itself is moisture-proof, a little moisture is no problem, but if there is water, put what is not useful

- Q: What is the difference between plastic floor composite floor

- But it is expensive, hardwood resource consumption, the installation of heavy workload, difficult to maintain (fear of fire, fear of water, afraid of tide) and floor width direction produced larger size changes with changes in relative humidity.

- Q: Home decoration with plastic floor, please? What are its strengths and weaknesses?

- Plastic floor has many advantages,:Elastic, comfortable, can give people a warm feeling; 2 surface in UV processing, pollution resistant, easy to clean; 3 green environmental protection, does not contain formaldehyde, inhibit the growth of bacteria; 4 case of water stains, good skid resistance,

- Q: Home decoration house, because there is no time, all to the decoration company, now just installed, found the decoration company to use in the bedroom floor is only 0.7 cm thick, and skirting the bedroom are plastic, and the rest of the baseboard and tried hard to break. I would like to ask you how long this line can be used? Need to be removed and replaced with good quality? Will be removed when the...

- The thickness of the wooden floor should be stipulated in the contract, if you spent 1.2 cm price, he gave you installed 0,7 cm

- Q: Warm the house, with plastic floor?

- Of course, there is one thing to tell you is that if you choose this floor, we must find authentic professional construction ability to ensure that the service agent to buy. Hair with the ground need to self leveling, the entire construction process should be very professional and very formal, to fully level, otherwise ugly. Now my floor has been used for two years, has not found quality problems. But compared to the advantages and disadvantages of other types of floor is: 1, no stone floor or cold feeling, 2 color, flower type, easy to clean wear many 3 disadvantages: 1, many people think that the lack of a sense of high-end 2, encountered organic solvent pollution is very difficult to clean

- Q: What is the plastic floor?

- Plastic floor, plastic floor. Plastic floor according to the operation state can be divided into blocks (or tiles) and coil (or floor) two. According to its material can be divided into hard, semi hard and soft (elastic) three. According to its basic raw materials can be divided into polyvinyl chloride (PVC) plastic, polyethylene (.PE) plastic and polypropylene (PP) plastics, etc..

- Q: What are the main construction process of laying plastic floor

- (3) plastic floor:Cutting, processing, scraping and wire grass, paste, rolling, curing.

Send your message to us

DIY Morden Anti-Skidding WPC Outside Deck

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords