DIN912 Hexagon Socket Cap Screw M2.5-M20

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

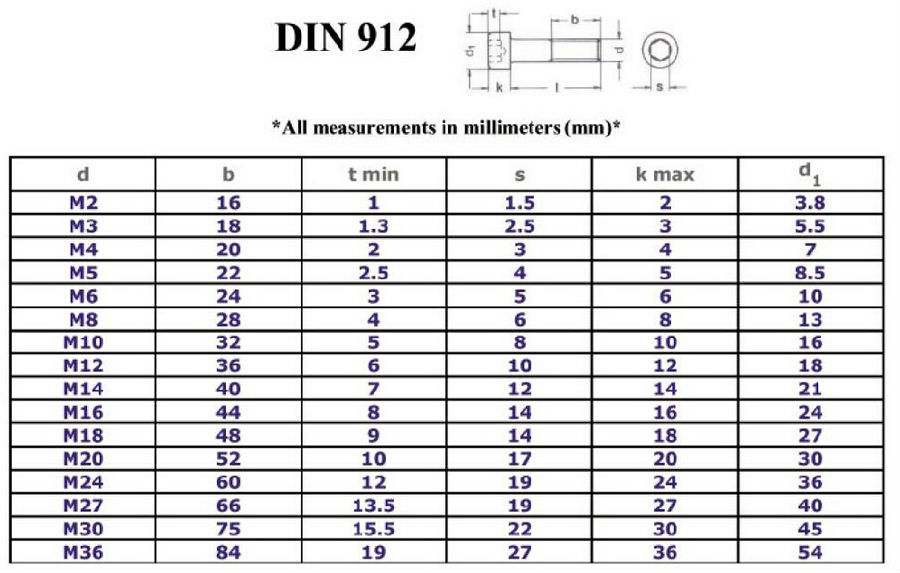

Product Name | DIN912 Hexagon Socket Cap Screw M2.5-M20 |

Material | Carbon Steel, Stainless Steel 201/ 304/ 316 or others. |

Size | M2.5--M20 |

Standard Model | DIN ANSI JIS ASTM |

Min Order | 1000piece/ pieces |

Packaging & Shipping

Packing | Inner Box + Carton Box + Pallet or Under Your Requirement |

Supply capacity | 10000000 piece/ pieces per month |

Delivery time | 5~20 days after deposit |

Export market | Asia, America, Europe, Africa, markets. |

Our Services

1. Reliable Supplier |

2. High Quality |

3. Standard Producing Technology |

4. Competitive Factory Price |

5. Fast Delivery |

Product Picture:

- Q: What is the meaning of the screw and the 4 and 8?

- Strength grade 4.8, nominal tensile strength of 400MPA products, yield strength 320 (nominal 80%). For details, please refer to GB3098.1 or ISO898-1. There are all indicators

- Q: How does the screw twist?

- The screw does not come out is generally caused by rust. Welding handle or heating is a commonly used method of disassembly, but the small size of the screw is not applicable; preferably with kerosene infiltration for several hours, and then use the vibration method of twisting

- Q: Gasket 300HV relative to what material?

- For the 140HV level can choose 08F, 08Al and 10, 10F, etc., the surface hardness can reach about 140HV

- Q: Install the shaft to install a few gaskets is appropriate?

- The axial shim changes need to take into account:Disc cleaning frame;After the extreme speed, the angle of the disc flywheel will not fall off the chain: a) in the largest piece of the disc in the disc, the largest piece of flywheel b) chain in the smallest piece of the disc, the flywheel in the smallest piece.

- Q: Please understand the friends of the self-tapping nails, screws, nuts production process, is the manufacturer's process. The more specific the more detailed the better

- According to the screw nut and thread size custom the corresponding mold, mold is done into the material, then the head - rubbing - surface treatment - the packaging is complete.

- Q: What material is used for spring washer

- Spring cushion ring: widely used in the mechanical and bearing capacity of the general mechanical products, which is characterized by low cost, easy installation, suitable for frequent loading and unloading parts. But the spring washer is very loose! Especially in Europe and the United States in the current requirements of high reliability products, the use of very low rate, especially the important load-bearing structure of the connection site has been abandoned for many years. Our country has some applications in the military, but has been improved to stainless steel materials. It is said that the steel spring washer in CASC was banned! It is also said to be very unsafe, there are two reasons for the 1 is up ring is hydrogen embrittlement of 2.

- Q: Fasteners are used in what areas?

- facilities, tools and instruments of human production will not be produced, people will no longer have electricity, no more tap water, no longer have a variety of automation equipment, no longer There is a lot of construction projects will not be able to solve the problem of connecting technology and a comprehensive shutdown, the level of human society productivity at least 300 years back, our lives will become incredible.

- Q: I would like to ask the car transmission inside the thrust washer (thrust washer) is used to do ah?

- Differential gear thrust washer is composed of silver alloy pressing, as well as plastics. Planetary gear thrust washer and half axle gear thrust washer shape are concave spherical and planar surface, there are many patterns like grooves or concave point in oil storage. The washer is the role of the friction reducing gear and axial differential housing, improve the transmission efficiency of the differential protection shell, thrust face not excessive wear, to prolong the service life of the differential housing, and maintain the normal meshing and transmission differential gear. The reason for the failure of the thrust washer is a serious lack of lubricating oil, or because of the small size of the stay and the erosion. Planetary gear broken, cross shaft fracture caused by the thrust washer damage, is generally rare. When the vehicle is traveling on a special road, or when the vehicle is in the mud, the differential frequency is used, resulting in excessive wear and thinning of the thrust washer. Thrust washer wear will make gear thrust surface shell, thrust surface acceleration loss, the differential gear axial shift, gear meshing clearance increases, the transmission space increases, causing the gear, cross shaft, differential housing bearing seat hole damage. Thus, the thrust washer is a reliable guarantee of differential action, but also to extend the life of differential parts. To this end, the vehicle should be updated on a regular basis when the thrust washer, to restore its proper clearance, to ensure the normal operation of the differential.

- Q: What is the invention of the screw?

- Hello hello as early as 2000 years ago appeared, but it will be used for fixed objects to be delayed until about 500 years ago. The first person who describes the spiral is the famous ancient Greek scientist Archimedes, which uses a wooden bucket to make a spiral object used to extract water from one plane to another plane for irrigation. By the middle of the Middle Ages, craftsmen used wood nails or metal nails to connect the wood structure of the building. This should be the real predecessor of the screw. In the 16th century, people began to produce spiral nails. And to the 18th world, people began a large-scale production of fastening objects with a screw nail. The afternoon is helpful to you

- Q: What is the size of the screw for the wall power switch installation

- Concealed switch generally M5 × 30 semi-round head screws, you can also use M4 × 30 tapping screws. Ming installed switch is used M5 expansion with M5's self-tapping screws.

Send your message to us

DIN912 Hexagon Socket Cap Screw M2.5-M20

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000000 piece/ pieces per month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords