Customized Colorful Food Safe BOPP Printed Packing Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Of Customed Colorful Bopp Printed Packing Tape:

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description Of Customed Colorful Bopp Printed Packing Tape:

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

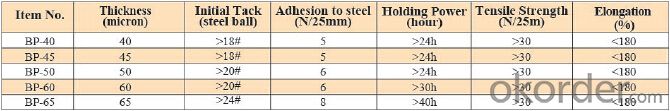

Typical Physical Reports Of Customed Colorful Bopp Printed Packing Tape:

Packaging Of Customed Colorful Bopp Printed Packing Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1280mm; length according to customers’ requirements

FAQ of Customed Colorful Bopp Printed Packing Tape:

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: What is the difference between acrylic and hot melt adhesive for packaging tape?

- Acrylic and hot melt adhesives are two common types of adhesives used for packaging tape, and they have some key differences. One major difference is the bonding strength. Hot melt adhesive is known for its excellent bonding strength, making it suitable for heavy-duty applications. It creates a strong and durable bond that can withstand rough handling and varying temperatures. On the other hand, acrylic adhesive typically offers a lower bonding strength compared to hot melt adhesive. While it is still suitable for most general packaging needs, it may not be as ideal for heavy or bulky items. Another difference lies in the application process. Hot melt adhesive is applied in a molten state and solidifies upon cooling. It is typically dispensed using a hot melt glue gun or a hot melt applicator. The quick setting time of hot melt adhesive allows for fast packaging operations, making it popular in high-volume settings. In contrast, acrylic adhesive is applied in a liquid form and requires some time to cure and form a strong bond. It can be applied using a hand dispenser or a tape gun, and it usually requires some pressure for optimal adhesion. Additionally, hot melt adhesive offers good adhesion to a wide range of surfaces, including cardboard, plastics, and metals. It is highly versatile and can be used for various packaging materials. Acrylic adhesive also adheres well to different surfaces, but it may not have the same level of compatibility with certain low-energy surfaces, such as polyethylene or polypropylene. Furthermore, temperature resistance is another factor to consider. Hot melt adhesive performs well in both high and low temperatures, maintaining its bonding strength. It can withstand freezing temperatures and heat without compromising its adhesive properties. Acrylic adhesive, while generally offering good temperature resistance, may not be as effective in extreme conditions, particularly at very high or low temperatures. In summary, the main differences between acrylic and hot melt adhesives for packaging tape lie in bonding strength, application process, surface compatibility, and temperature resistance. While hot melt adhesive provides superior bonding strength, fast setting time, and excellent temperature resistance, acrylic adhesive offers versatility, ease of application, and good adhesion to most surfaces. The choice between the two depends on the specific packaging needs, materials, and environmental conditions.

- Q: 2014, how can I sell the tape better?

- Small size, you can directly face the end users and wholesale retailers in this region, large-scale, you can go to the major wholesale market to find a larger customerFirst, your product advantage there is no matter how good the tape has shortcomings, when you go to sell to bring several tape, better and worse, you first find the tape several shortcomings, your products and other tape compare your advantage in that way. Customers know your product,

- Q: Does packaging tape come in different thicknesses for added durability?

- Yes, packaging tape does come in different thicknesses for added durability. The thickness of packaging tape is measured in mils, which refers to the thickness of the tape in thousandths of an inch. Common thicknesses for packaging tape range from 1.6 mils to 3.1 mils. Thicker tape is generally more durable and able to withstand heavy-duty applications. Thicker tapes are ideal for securing large or heavy packages, as they offer greater strength and tear resistance. Thinner tapes, on the other hand, may be suitable for lighter items or less demanding packaging needs. Thus, the availability of different thicknesses in packaging tape allows users to choose the most appropriate tape for their specific durability requirements.

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled. However, it is important to remove the tape from the packaging material before recycling.

- Q: Does packaging tape come in different lengths?

- Yes, packaging tape does come in different lengths. It is available in various lengths to cater to different packaging needs and requirements.

- Q: Can packaging tape be used for sealing construction or building materials?

- Yes, packaging tape can be used for sealing construction or building materials. While it may not be as durable or strong as specialized construction tapes, packaging tape can still provide a temporary or quick solution for sealing materials such as cardboard, plastic sheets, or lightweight panels. It can be used to secure temporary covers, attach protective layers, or hold materials in place during construction or renovation projects. However, for long-term or heavy-duty applications, it is recommended to use tapes specifically designed for construction purposes, as they are more resistant to weather, UV rays, and have stronger adhesive properties.

- Q: Does packaging tape have an expiration date?

- No, packaging tape does not have an expiration date.

- Q: Is packaging tape resistant to punctures or tears?

- Yes, packaging tape is generally resistant to punctures or tears. It is designed to be strong and durable, specifically for securing and sealing packages. Packaging tape is made from materials such as polypropylene or polyester, which have high tensile strength and offer excellent resistance to punctures or tears. Additionally, packaging tape often has adhesive properties that further enhance its ability to withstand punctures or tears. However, it is important to note that the level of resistance may vary depending on the specific type and quality of packaging tape used.

- Q: Does packaging tape come in different materials for specific applications?

- Yes, packaging tape does come in different materials for specific applications. One common type of packaging tape is made of polypropylene, which is a versatile material suitable for general-purpose packaging. It is strong, durable, and resistant to moisture and temperature changes, making it suitable for a wide range of applications. However, for more specialized uses, different materials may be needed. For example, if you are packaging items that require extra security or tamper-evident features, you may opt for security tape. This type of tape is often made of a thicker and stronger material, such as polyester or reinforced paper, and is designed to leave a visible mark or message when tampered with. In certain cases, you may need to use packaging tape that is specifically designed for use in extreme temperature conditions. For instance, if you are shipping goods that will be exposed to freezing temperatures, you may need to use freezer-grade packaging tape that remains adhesive and effective in low temperatures. Similarly, some applications may require tape that can adhere to difficult surfaces like corrugated cardboard or recycled materials. In such cases, you may choose a packaging tape with aggressive adhesive properties or one that is specifically formulated for adhesion on challenging surfaces. Additionally, there are also eco-friendly options available for those who prioritize sustainability. Environmentally friendly packaging tapes are often made from renewable or recycled materials and use non-toxic adhesives. Overall, the choice of packaging tape material depends on the specific needs of the application, such as security, temperature resistance, surface compatibility, or environmental considerations. It is always important to select the appropriate tape to ensure the safe and secure packaging of your items.

- Q: I saw a lot of different sizes of sealing tape on the Internet. Some are very thick and some are thin. Will the thickness of the same number be the same in the same number of yards? Some 100Y have around 1.5cm of the flesh, but some 100Y only about 0.7cm of the flesh, what is this possible? Or is it true or false? Ask the personage inside course of study to help solve!

- 100 yards, 150 yards, can be found everywhere! To do adhesive tape, we must find good faith partners! Professional to undertake all kinds of sealing tape production and wholesale

Send your message to us

Customized Colorful Food Safe BOPP Printed Packing Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords