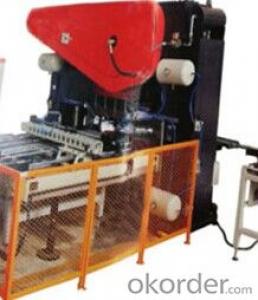

Curling Machine to Curl Tin Can Lid for Round Tin Can Box Making Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Curling Machine to Curl Tin Can Lid for Round Tin Can Box Making Line Usage and Applications

Type:Packaging Line

Condition:New

Application:Food, Beverage, Chemical, Machinery & Hardware

Packaging Type:Cans

Packaging Material:Metal

Automatic Grade:Automatic

Driven Type:Electric

Voltage:380V

Place of Origin:Zhejiang, China (Mainland)

Certification:CE

After-sales Service Provided:Engineers available to service machinery overseas

Curling Machine to Curl Tin Can Lid for Round Tin Can Box Making Line Main TechnicalParameters

1.CNC Automatic Puching

2.PLC System

3.High Speed & Efficiency

4.Easy Dies Changeover

| Name Usage | Curling Machine |

| Usage | It's usad for covers curling |

| Capacity | 40 covers/min |

| Cover Diameter | 30-170 mm |

| Power | 0.37 kw |

| Weight | 150 kg |

| Dimension | 740*1100*590 mm |

- Q: What is the design basis of automated packaging?! Just for today!

- Increase productivity and reduce process costGerman packaging machinery, especially beverages, beer filling machinery and food packaging machinery, with high speed, complete sets, high degree of automation and good reliability and so on. Beverage filling speed up to 1200 bottles / D, when the cigarette packaging 12000 / min.. Increasing the speed of the machine is a complex problem. The faster the piece production cost is, the higher the use area of the workshop is. In addition, the speed of the motor is limited, so do not think how fast, how fast. In general, the speed increase by 15%, 20%, will lead to a series of complex problems. In addition to increasing the speed, the productivity can be solved from other channels:1. continuous or long work. Packaging machinery works a batch type and continuous type, design, design should strive for continuous work, also can improve the productivity; one device may also have multiple production lines, the production of the same product or several different products, but must improve the reliability.2. reduce scrap rate and provide fault analysis system. The loss of waste to production is enormous, not only product loss, but also material loss. So try to force to reduce the rejection rate; packaging machinery sale should also provide maintenance services for the fault analysis system, the modal analysis is carried out to find fault, or through the Inter network for remote diagnosis, the maximum to meet customer needs. In the future, the packaging machinery will be further intelligent, that is, the equipment itself to find fault, to solve their own failure, to reduce waste rate and failure rate, so that the normal productivity can be improved.

- Q: Hello, I just do packaging machinery, foreign trade, I do not know how to search customers ah.For example, our products have machines that can pack candy and cookies. Do you want to search for candy or biscuit manufacturers and then recommend them to our products? These candy manufacturers search through the Internet to recommend, the effect is good?

- If you have your own website here, through the optimization and promotion, to promote their products out, the customer concern, love content search, when people search through GG to see your home site, you may consult. There are many ways

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Buddy, you go to Taobao to buy a few hundred vacuum packaging machine, the 3 days is no problem, I suggest you go to buy a good brand, this thing hundreds of, garbage is easy to bad, shelf life 3 days, basically no problem

- Q: Bread packing machine Product features

- 4., high sensitivity photoelectric eye mark tracking, digital input seal cutting position, so that the seal cutting position more accurate.5. temperature independent PID control, better for all kinds of packaging materials.6. 、 positioning stop function, no sticking knife, no waste of coating.7. drive system is simple, more reliable work, more convenient maintenance.8. all control is realized by software, which is convenient for function adjustment and technical upgrading, and never falls behind.

- Q: How much is the tableware wrapping machine?What's the price of the tableware wrapping machine?

- Tableware packaging machine machine standard price of about 38000, excluding tax, tableware packaging machine is designed for tableware (e.g., chopsticks, bowls, dishes and so on) a modern packaging machinery packaging, this machine is mainly composed of conveyor, packaging machine, output machine, shrink machine, composed of four parts.

- Q: Which friend is an expert in mechanical equipment or a better understanding of sealing machines? Tell me how to identify the equipment

- There are PLC control ah, if it is fully automatic, then ask the quality of sealing ah, it is best to let manufacturers give you a live demonstration, the soft power depends on the size of the factory, ah, after-sales service ah!

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Now the standard of living has improved, basically the vacuum bag. This will improve the product's shelf life, preservation time is longer, more conducive to product sales.

- Q: Three dimensional packaging machine, transparent film packaging machine, transparent film three-dimensional packaging machine industry standards

- English Name: Transparent, film, fold, wrapping, machineClassification: machinery, general machinery and equipment, >>J83 storage equipment, loading and unloading machineryICS classification: packing and conveying of goods, >>55.200 packaging machinery

- Q: Will the Internet be too passive? Telephone marketing, what kind of food can be found in the factory, such as the phone, people basically do not need, and all have. Does the salesman run the market? How do you run? Thanks for the direction...

- (especially the telephone communication, stop talking no worries) I think you should understand the specific situation, your target customers first, for example: mechanical models currently in use and the time of purchase, production efficiency, what will be improved after the replacement, can recover the cost of even a few years, these are all what you should do in advance homework.

- Q: Calendering, extrusion, blow molding, pressing, plastic (vacuum forming) and what is the rotational molding

- Plastic forming and processing methodPlastic molding is an engineering technology, involves the plastic into all kinds of plastic products in the process. The transformation process tends to happen in one or more of the following conditions, such as polymer rheology and physical and chemical properties of the change.

Send your message to us

Curling Machine to Curl Tin Can Lid for Round Tin Can Box Making Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords