Construction Hoist SCD270 Material Handing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of SCD270 Construction Hoist Description

To serve the increasing demand for highrise construction, we developed the high speed VF hoist, with a max.lifting speed of 96 m/min.

It has the following structure:

1. Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

2. Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process, and ensures automated leveling.

3. Adopts open loop V/F control: the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoids slipping during downward stopping of hoist.

4. The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the energy consumption and mitigates effects to on site electric equipments.

5. The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack,pinion and the brake and prolongs the spare parts'life.

6. The VF system also has the over voltage protection, low voltage protection, overcurrent, overload and anti-stalling protection functions.

7. The System applies the special software for hoists developed by our company, making the operation more safe and reliable.

Main Features of SCD270 Construction Hoist

1. The recomended cage dimension(L*W*H)(m): 2.0*1.0*2.5, 2.5*1.0*2.5, 2.5*1.3*2.5, 3.0*1.5*2,5, 3.2*1.5*2.5, 3.8*1.5*2.5, 4.0*1.5*2.5, 4.2*1.5*2.5 etc. We can also manufacture cages of other size according to the user.

2. The cage and the door material can be aluminum molded board, punched-plate, figured aluminum board or other type according to yout requirements.

3. The mast section and the tie-in surface can adopt paint-spray, or hot galvanizing processing.

4. Both domestic and imported driving systems are available.

SCD270 Construction Hoist Specifiction

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage building hoist can be changed into single cage type,

| Type | Payload(kg) | Lifting Speed (m/min) | Motor Power(kw) | Safety Device | ||

| Single Cage Hoist | No Counterweight | SC100 | 1000 | 0~60 | 3*11 | SAJ30-1.4 |

| SC120 | 1200 | 0~60 | 3*11 | SAJ30-1.4 | ||

| SC160 | 1600 | 0~60 | 3*15 | SAJ30-1.4 | ||

| SC200 | 2000 | 0~60 | 3*15 | SAJ40-1.4 | ||

| SC250 | 2500 | 0~60 | 3*18.5 | SAJ50-1.4 | ||

| SC270 | 2700 | 0~60 | 3*18.5 | SAJ50-1.4 | ||

| SC300 | 3000 | 0~60 | 3*22 | SAJ50-1.4 | ||

| SC320 | 3200 | 0~60 | 3*22 | SAJ50-1.4 | ||

| With Counterweight | SCD200 | 2000 | 0~60 | 2*15 | SAJ40-1.4 | |

| SCD250 | 2500 | 0~60 | 2*18.5 | SAJ50-1.4 | ||

| SCD270 | 2700 | 0~60 | 2*18.5 | SAJ50-1.4 | ||

| SCD300 | 3000 | 0~60 | 3*15 | SAJ50-1.4 | ||

| SCD320 | 3200 | 0~60 | 3*15 | SAJ50-1.2 |

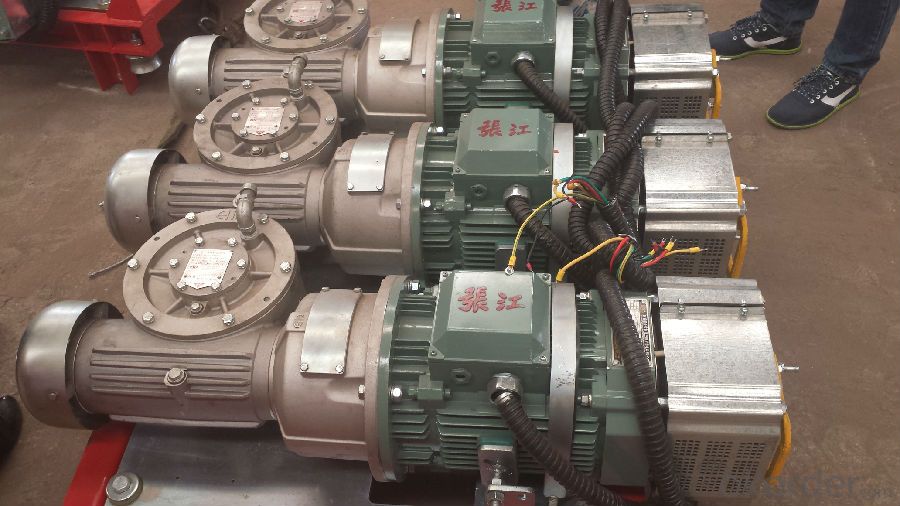

Images of SCD270 Construction Hoist

FAQ of SCD270 Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: How does the driver of the construction elevator do the search for a sudden power failure

- When the elevator in the operation of the midway stop due to power outages or other reasons, the manual can be decreased, the end of a motor brake electromagnet manual release slowly shake handshandle pull outward, slowly slide down the ladder cage, ladder cage fall shall not exceed the rated speed, manually drop must be conducted by professional maintenance personnel.

- Q: Can a building hoist experience technical issues or fail to operate properly?

- <p>Yes, a building hoist can malfunction. Like any mechanical system, hoists are subject to wear and tear, component failure, and can be affected by human error. Malfunctions may include mechanical breakdowns, electrical faults, or safety device failures. Regular maintenance, inspection, and adherence to safety protocols can reduce the risk of hoist malfunctions.</p>

- Q: This question asks for the method to determine the maximum weight a building hoist can lift.

- <p>The lifting capacity of a building hoist is calculated by considering several factors including the hoist's motor power, the strength of the hoist's construction materials, and the safety factor. The manufacturer usually provides the maximum lifting capacity based on these factors. To calculate it manually, you would need to know the motor's lifting force, the efficiency of the hoist's mechanical system, and apply a safety factor to ensure the hoist operates within safe limits. It's important to follow the manufacturer's guidelines and never exceed the specified lifting capacity to prevent accidents and ensure the hoist's longevity.</p>

- Q: This question asks for safety guidelines and procedures to be followed when operating a building hoist.

- <p>To use a building hoist safely, follow these guidelines: Ensure the hoist is regularly inspected and maintained by qualified personnel. Never exceed the hoist's load capacity. Keep the hoist and its surroundings clean and free from debris. Always use safety hooks and never leave the hoist unattended when in use. Ensure all safety features, such as limit switches and emergency stop buttons, are functioning correctly. Train operators on the proper use of the hoist and adhere to all manufacturer's instructions. Never use a hoist if it shows signs of damage or malfunction. Always wear appropriate personal protective equipment (PPE) when operating a hoist.</p>

- Q: Is it possible to replace an electric control panel with a manual lever in a lifting system?

- <p>While it is theoretically possible to use a manual lever as a substitute for an electric control panel in a lifting system, it is not advisable. Manual levers lack the precision, safety features, and control capabilities of electric control panels. They also cannot provide the same level of feedback or automation. Electric control panels are designed to ensure safe and efficient operation, with features like emergency stop buttons, overload protection, and remote monitoring. Manual levers can pose safety risks and may not meet the operational requirements of modern lifting systems.</p>

- Q: This question asks about the routine maintenance procedures for a building hoist, which is a piece of equipment used in construction to lift materials and personnel.

- <p>To maintain a building hoist, follow these steps: Regularly inspect the hoist for any signs of wear or damage, especially the cables, pulleys, and safety mechanisms. Lubricate moving parts as per the manufacturer's guidelines to reduce friction and prevent rust. Ensure all safety features, such as emergency stops and limit switches, are functioning correctly. Keep the hoist clean and free from debris, which can interfere with its operation. Check the electrical connections for any signs of corrosion or damage. Perform load tests to confirm the hoist's lifting capacity and ensure it meets safety standards. Always follow the manufacturer's maintenance schedule and guidelines, and have a professional service the hoist periodically.</p>

- Q: This question asks for the procedure to safely lower an object after it has been lifted using a building hoist.

- <p>To safely lower an object after using a building hoist, ensure that the area below is clear of people and obstacles. Slowly release the hoist's brake or control mechanism, allowing the object to descend gradually. Keep a steady hand on the controls to maintain a controlled descent. Monitor the object's position and communicate with ground personnel if necessary. Ensure all safety hooks and attachments are secure until the object reaches the ground. Once the object is safely on the ground, secure it and disconnect it from the hoist. Always follow the manufacturer's guidelines and safety protocols for the specific hoist being used.</p>

- Q: Explain the key differences between electric and hydraulic lifting equipment, including their power sources, efficiency, and applications.

- <p>Electric lifting equipment is powered by electric motors and typically operates through cables or batteries, making them quieter and more environmentally friendly. They are often used in indoor settings where noise and emissions are a concern. Hydraulic lifting equipment, on the other hand, uses hydraulic fluid and pistons to generate force, providing high power and torque. They are commonly used in heavy-duty applications and outdoors. Electric systems are generally more energy-efficient and have lower maintenance costs, while hydraulic systems offer greater power density and can handle heavier loads.</p>

- Q: Is it possible to utilize a manual building hoist for the purpose of lifting heavy objects?

- <p>Yes, a manual building hoist can be used for lifting heavy objects. These hoists are designed to handle significant weights and are commonly used in construction for moving materials and equipment to various heights. They are operated manually, often with a hand crank or lever, and are equipped with safety features to prevent accidents. However, it's crucial to ensure that the hoist is rated for the weight of the objects being lifted and that all safety protocols are followed to avoid any accidents.</p>

- Q: This question asks for the cost of a building hoist, which is a type of construction equipment used for lifting materials.

- <p>The cost of a building hoist can vary significantly depending on factors such as the hoist's capacity, type, and features. On average, a basic building hoist can cost anywhere from $10,000 to $50,000. However, for more advanced models with higher capacities or additional safety features, the price can range from $100,000 to $200,000 or even more. It's important to consider the specific needs of your construction project and consult with equipment suppliers for accurate pricing.</p>

Send your message to us

Construction Hoist SCD270 Material Handing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords