Construction Hoist SCD250/250 with Two Cage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction Hoist Description

Feature: Construction Hoist Condition: New Application: Construction

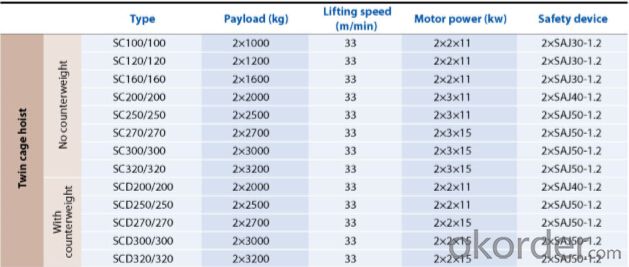

Payload(kg):2*2500 Lifting Speed(m/min):33 Motor Power(kw): 2*2*11

Safety Device: 2*SAJ50-1.2 Cage: Twin Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD250/250

Packaging & Delivery of Construction Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Construction Hoist

● The gearing adopts imported bearing, enameled cable, and oil seal.

● The electric parts adopt products from world renowned manufactures such as Schneider, Siemens, and LG.

● The racks and pinion adopts special material and heat-treatment technique, which prolong the life of these parts.

● The steel structure uses quality steel from famous domestic manufactures.

● The surface of the structure can apply paint-spray, parkerozing baking finish or hot galvanizing processing according

to users requirements,

● The cage can be produced and decorated by aluminum molded board, punched-plate or figured aluminm board.

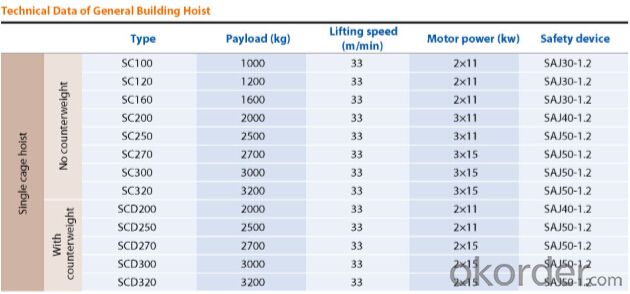

Construction Hoist Specifiction

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: What about the energy efficiency of the escalator

- Variable frequency construction elevator energy saving effect general. Frequency conversion is not energy efficient. The difference between the frequency and the common machine is the smoothness and speed of the operation. Frequency conversion speeds up to 90m / 1 minutes and the average is only 35m / 1 min Frequency conversion when parking is slow down and stop Ordinary is directly stop delay parking and adjustment made door light who bow Angle decyl with brush spring connection will be better. The frequency conversion requires the site voltage to be strictly a little bit looser than the voltage requirement Energy consumption is: according to the elevator drive mechanism for general three transmission two kinds of the elevator are three 11 kw motor, that their energy consumption are 3 x 11 = 33 kw is hours each hanging basket consumes electricity 33 degrees, the actual power consumption will be bigger.

- Q: This question seeks to understand the benefits and drawbacks associated with the use of hydraulic building hoists in construction.

- <p>Hydraulic building hoists offer several advantages, including high lifting capacity, smooth and controlled lifting, and lower maintenance costs due to fewer moving parts. They are also energy-efficient and can be easily integrated into existing systems. However, they have some disadvantages. For instance, they can be more expensive to purchase initially compared to other hoist types. Additionally, they may require more space for installation and can be sensitive to extreme temperatures, which might affect performance. Lastly, hydraulic systems can be prone to leaks and require regular fluid checks and maintenance to prevent system failure.</p>

- Q: This question asks for a comparison between manual and automatic lifting systems used in construction equipment, highlighting their distinct features and operational differences.

- <p>Manual lifting systems in construction equipment rely on human effort to lift and move materials. They are often less expensive, require less maintenance, and are suitable for lighter loads or smaller-scale projects. However, they are labor-intensive, can be slower, and pose higher risks of injury due to the physical demands. Automatic lifting systems, on the other hand, use mechanical or electronic means to lift and move materials. They are more efficient, can handle heavier loads, and reduce the risk of injury by minimizing manual handling. These systems are often more expensive and require regular maintenance but offer precision, speed, and ease of operation, making them ideal for large-scale construction projects.</p>

- Q: Is it permissible to use a building hoist for lifting people?

- <p>Building hoists are not designed for lifting people and doing so can be extremely dangerous. They are specifically engineered for the transportation of materials and equipment in construction settings. Using a building hoist to lift people violates safety regulations and can result in severe accidents. Always adhere to the manufacturer's guidelines and local safety laws, which prohibit the use of building hoists for carrying personnel.</p>

- Q: This question asks for the cost associated with purchasing and installing a building hoist.

- <p>The cost of buying and installing a building hoist can vary significantly depending on several factors. The type and capacity of the hoist, the height of the building, and the complexity of the installation are key determinants. On average, the cost can range from $10,000 to $50,000 for the hoist itself, with installation costs potentially adding another 20-50% to the total. However, for very tall buildings or specialized hoists, the price can exceed $100,000. It's crucial to obtain quotes from multiple suppliers and installers to get an accurate estimate for your specific project.</p>

- Q: Is it possible for one operator to manage several lifting devices, including a Building Hoist, at the same time?

- <p>Yes, it is possible for a single operator to handle the operation of multiple lifting devices, including Building Hoists, depending on the specific equipment and safety regulations. Modern building hoists are often designed with advanced controls that allow for efficient management of multiple units. However, this must be done in compliance with local laws and safety standards, which may require additional training or certifications for the operator. It's crucial to ensure that the operator has the necessary skills and that the operation does not compromise safety.</p>

- Q: Is the elevator detail a construction plan? Do you have a detailed picture of the elevator?

- There is a detailed picture of the elevator. The structure of the elevator well and the layout of the embedded parts.

- Q: This question asks for a description of the process of operating a building hoist using a remote control system.

- <p>To use a remote control system for a building hoist, first ensure that the hoist is properly installed and inspected for safety. Turn on the hoist's power supply and ensure the remote control is synced with the hoist. Familiarize yourself with the control panel, which typically includes buttons for up, down, stop, and emergency stop. Operate the hoist by pressing the up or down buttons to lift or lower the load. Always monitor the load's movement and communicate with workers on site. Use the stop button to halt the hoist if needed, and the emergency stop button in case of an immediate hazard. Regularly check the hoist's operation and maintain the remote control system to ensure smooth and safe operation.</p>

- Q: Is it possible for a hydraulic cylinder in a building hoist to be serviced or replaced by individuals other than the manufacturer?

- <p>Yes, a hydraulic cylinder in a building hoist can be repaired or replaced by qualified individuals or companies other than the manufacturer. However, it is crucial to ensure that the service provider has the necessary expertise and follows the manufacturer's specifications to maintain safety and performance standards. Using non-genuine parts or improper installation can lead to safety hazards and void warranties. It is always recommended to consult with professionals who are familiar with the specific hoist model and have experience in hydraulic systems repair and maintenance.</p>

- Q: What are the expenses involved in buying and maintaining a building hoist?

- <p>The costs of purchasing and operating a building hoist include the initial purchase price, which can range from $10,000 to $50,000 depending on the model and capacity. Operating costs involve maintenance, which may be around $1,000 to $5,000 per year, and electricity for operation, which can vary based on usage. Additionally, there may be costs for installation, insurance, and potential repairs. Labor costs for operating the hoist should also be considered, as well as costs for compliance with safety regulations. These costs can vary widely based on location, the specific hoist model, and the scale of operations.</p>

Send your message to us

Construction Hoist SCD250/250 with Two Cage

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords