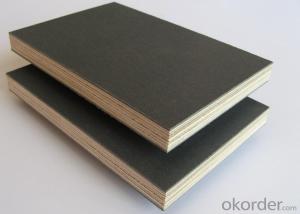

Commercial Plywood Lumber Composites Plywood Hardwood Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commercial Plywood Lumber Composites Plywood Hardwood Plywood

Product Description:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Formaldehyde Emission Standards: E2

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: Teak

· Face/back: teak, oak, beech, ash walnut, sapele etc

· Thickness: 3.0mm,3.6mm,4.0mm,4.6mm,5.2mm 12mm,9mm,as your request

· Core: poplar, combi, hardwood, MDF

· Glue: melamine: MR, E2,E1

Packaging & Delivery:

· Inter packing: 0.20mm plastic bag.

· Outer packing: pallets are covered with plywood or carton and then steel for strength

· Delivery Detail: 30days after receiving LC or deposit

Product Specification:

Detailed Product Description | ||

Features | Face/back | melamine /veneer/pvc/hpl/ev (As you required) |

Glue | E1 or E2 ... (As you please) | |

Size | 1220*2440mm or 1830*2440mm | |

Thickness | 2.0mm~35mm | |

Core | poplar, combi etc. | |

Moisture | normal, moisture-proof, water-proof, eco-friendly | |

Payment & Shipping | MOQ | 1*20' container (negotiable) |

Port | Qingdao | |

Packing details | Inter packing: 0.20mm plastic bag Outer packing: pallets are covered with plywood or carton and then steel for strength | |

Delivery time | Within 15~20 days after 30% deposit or L/C | |

Payment terms | L/C,T/T | |

Supply ability | 50*40' HQ per Month | |

Advantages | Guarantee of 2 years | |

Competitive price | ||

ECO- friendly—— E1 grade, CARB P2 certificated | ||

High quality and excellent workmanship | ||

Company Info:

OKorder.com is an online building materials trading platform funded by CNBM (listed 267th on Fortune Global 2014) and is operated by CNBM International. CNBM International has more than 20 years trading experience and has established close business relationships with clients from over 160 countries.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, if needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Roof 100mmEPS sandwich board how much money a square

- 100MM look at the thickness of steel is generally around 60-85. Need to be able to stand letter me, my Jiangsu

- Q: There is a comprehensive building, a two-story canteen, three-story activity room, the roof for the Caigang sandwich panel roof, the building fire rating for the two, the roof sandwich board design using polystyrene foam sandwich panels can?

- Can not. Polystyrene foam sandwich panels are mostly flammable and flammable, preferably flame retardant, and the burning properties of their materials do not meet the requirements of Grade II refractory grade buildings. Our province has been a few cases of Caigang sandwich panel roof fire cases, due to sandwich material led to the rapid expansion of fire.

- Q: Is not allowed to use foam sandwich color plate

- Hello! Now the state banned the use of foam sandwich color steel plate, also known as foam sandwich panels, because the foam sandwich board fire rating is poor, the state is prohibited. Now the market generally use rock wool color plate, which is used instead of rock wool composite board, fire rating up to A level. There are also some high-end customers with polyurethane color plates instead of using them, so the cost may be higher. Choose a most suitable for their own sandwich color plate can be used. After all, who is not the wind to the wind, the ability to do so

- Q: The foam sandwich panels of the insulated chicken coop are burned! How to do hollowing out?

- Specific solutions: 1 to reduce the brine wave degrees; 2 Add GX-1 # Magnesium Modifier; 3 to do a good job of ventilation and cooling work.

- Q: What brand of rock wool sandwich board is good

- Shandong Yongguang building materials technology companies to produce rock wool composite board has more than 10 years of history, is located in Jiangbei largest steel production base - Zibo Zhoucun, color steel plate, rockwool core material, such as a complete upstream and downstream industry chain, Has an unparalleled low cost advantage. Save money is the last word! Welcome to the majority of steel installation company to visit.

- Q: Is the foam sandwich plate formaldehyde?

- Use to enjoy the formaldehyde detector under the test to know whether it contains formaldehyde, and large screen real-time display, triple alarm preset function, Portable compact hand.

- Q: Plan to use Caigang sandwich panels to do the roof. The wall is brick wall. Ask how the sandwich panel is fixed on the brick wall ah?

- Wall to do reinforced concrete ring beam cap, and then fixed on the ring beam C-keel, sandwich plate fixed on the keel, complete.

- Q: New rock wool sandwich board polyurethane edge how much money one meter

- Do not do the fire to investigate or deal with either Yanmian board or polyurethane board price is the polyurethane invoice does not send about 130% of the price of rock wool

- Q: Color steel sandwich panels

- It depends on what grade you choose the color plate, including the surrounding environment and many other effects. The last one or two years on the rust rotten, the current market should be the best Baosteel color plate, but the price is more expensive, to the color steel sandwich board than the same level of other small manufacturers to 10 to 20 yuan Per meter, under normal circumstances, if you want to live for a long time, I suggest you do not use materials than low 0.5mm thick color plate, the general manufacturers can also use the color plate 8-15 years, if the board is too thin, then not Good to say, the thinner the color plate, the faster the corrosion, if the use of Baosteel's color plate, with more than 15 years should not be a problem. Due to price factors, the general small manufacturers do not have Baosteel color plate.

- Q: Pressure-type sandwich color plate thickness 100mm What is the socket type

- In general, this type of plug-in, such as Heilongjiang, Czech Republic, the European-style rock wool board has plug-in.

Send your message to us

Commercial Plywood Lumber Composites Plywood Hardwood Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords