Cold forming blister aluminum foil of good reputation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

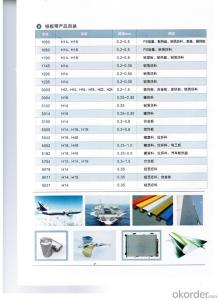

OPA/AL/PVC Cold-forming compound aluminum hard chip | |

·Structures |

- Q: What is aluminum foil?Direct rolling with metallic aluminium

- A metal foil: Aluminium directly rolled into sheets of hot stamping material, the effect of stamping and silver foil stamping similar effects, it is also called the false. Because of its soft texture and good ductility, it has a silvery luster. If the rolled sheet is made of sodium silicate on the offset paper, the foil can be printed. But the aluminum foil itself is easy to oxidize and the color is dull, friction, touch and so on will fade. Therefore, it is not suitable for the long-term preservation of books, covers and other hot stamping.

- Q: Such as the title: this insulation foil usually can get viscous tropical buy where (small buy), I'm going to ask the hardware stores and supermarkets are not the adhesive foil? Is it called "aluminum foil tape"? If yes, please advise, thank you!

- Thickness is different, the price is different, about 2-5 yuan / dish, it is recommended to buy a bit thicker, anti-aging ability better

- Q: Aluminum foil waterproof material, how much does it cost for a square?

- It depends on whether you are using SBS waterproof membrane or self-adhesive waterproof coiled material

- Q: When installing gas water heater in our house, the installation master will connect the aluminum foil smoke pipe directly to the smoke exhaust port of the machine, but the Internet says it can not be installed like this. What's wrong with this?

- Case 2:1, smoke pipe distance from the ceiling in accordance with the requirements should be greater than 50mm, but the machine smoke pipe almost affixed to the ceiling, a serious violation of regulations;2, open the hole in the wall is not sealed, connections are not used aluminum foil sealing tape; the flue gas flow backward user ceiling blackened, cause accidents.

- Q: What is a composite aluminum foil molded poly vinyl foam board, and what is a composite aluminum foil extrusion poly vinyl vinyl insulation board, the two how to distinguish?Please try to be more specific

- 5, flame retardant properties of EPSXPS can reach B1 B26, the price of EPS is lower than XPSConclusion, if used in air conditioning, air duct and so on, XPS is superior in performance analysis,

- Q: Car sunshade and black aluminum foil which is good, and the aluminum foil is white or cartoon, mainly considering the shading effect

- In the less hot season, colour patterns can be placed out of the room. If the weather is very hot, the foil can be turned out to ensure the reflection of sunlight. In the purchase before the sun block, it is best to choose to take a sucker, the material should be more hard texture. "Light plate" or "too cheap" front sun block is not enough itself, it is easy to fall, so do not seek cheap. In general, there are brands of front sun block, packaging materials used better, there are special placement of suction cups, sucker is not easily squeezed. Worse brands, ten to one, a sucker is squeezed, and the remedy is to put it in boiling water for a while.

- Q: Without the backing of aluminum foil and aluminum foil backing is what is the difference between what is their characteristics?

- My factory main operation is aluminum foil roughing mill in 20 years ago, a machine about one million, more than 170 kW, zhenshuang!!!

- Q: What's the use of aluminum foil?

- Aluminium foil for electrolytic capacitorElectrolytic capacitor with aluminum foil is a kind of work in polar conditions of corrosive materials, structure of aluminum foil have higher requirements, the aluminum foil is divided into three types: the cathode foil thickness is 0.015mm ~ 0.06mm; high pressure foil thickness is 0.065mm ~ 0.1mm, with the requirements of production of high purity aluminum foil; low pressure foil thickness is 0.06mm ~ 0.1mm.

- Q: Where are the aluminum foil lunch boxes used?

- Baking is pretty. There are also some people who use it for household use. Relatively light, easy to carry

- Q: What kind of food grade aluminum foil does it mean?

- If it is only for serving dishes and serving food, you can use baking paper, which is safe and non-toxic.The silver layer in Tetra Pak is also aluminum, which is an aluminized composite film.

Send your message to us

Cold forming blister aluminum foil of good reputation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords