Cold drawn carbon fiber cut-off

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold drawn carbon fiber cut-off

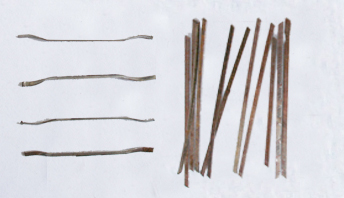

Concrete steel fiber: to cut off the thin wire method, cold-rolled strip steel cutting, milling or steel ingot quickly condensed into the legal aspect ratio (the ratio of fiber length to its diameter, when the fiber non-circular cross-section, using the conversion equivalent sectional diameter area of a circle) of 40 to 80 fibers.

Steel fiber is mainly used in the manufacture of steel fiber reinforced concrete, any method of production of steel fiber reinforced can play a role in concrete. The reinforcing effect of the fiber depends on the strength of the matrix (fm), the fiber aspect ratio (fiber length l and the diameter of the steel, the ratio d, the I / d), the volume ratio of the fiber (steel fibers of the percentage of the volume occupied by the concrete steel ), the adhesive strength between the fibers and the matrix (τ), and the fiber distribution in the matrix and orientation (η) of. When steel fiber reinforced concrete damage, mostly fibers are pulled out rather than pulled off, thus improving the bond strength between the fiber and the matrix is one of the main controlling factor in improving fiber reinforced effect.

Adding steel fiber concrete compressive strength, tensile strength, flexural strength, impact strength, toughness, toughness and other properties have been greatly improved.

Cold drawn carbon fiber cut-off

Cold drawn steel wire having a diameter of 0.4 ~ 1.0mm, and cut into a predetermined length in accordance with the short fibers.

Product Features:

Cold drawn steel wire made of steel fiber tensile strength of up to 1000 ~ 2000MPa, but its surface is smooth, the poor and the concrete or cement mortar matrix bond strength. In order to enhance the bond strength of steel fiber and the matrix, often can change the shape of steel fibers, namely, the production method of deformed steel fibers to be addressed. Its common methods are pressure ridge France, wave method, hook method.

Product specifications and models:

No. Type Length (mm) Diameter (mm) Tensile strength (MPa) shape

1 wire cutting type 20-60 0.4-1.0 ≥1100 corrugated

2 wire cut type 20-60 0.4-1.0 ≥1100 straight type

3 wire cut type 20-60 0.4-1.0 ≥1100 Bow

Application:

Carbon fiber cold Joan pattern type:

The basic shape and cut of the same type products are equivalent, but the tensile strength of monofilament has greatly improved, up 1100MPA more suitable for large area concrete crack key projects.

Cold-drawn steel fiber end hook:

This is the combined effect of the best products, with its high intensity (greater than 1100MPA), bending (more than ten times constantly) and riveted the best combination of the strongest end hook shape, and its products can be described as steel fiber of the family. "the boss. "

End hook steel fiber, steel fiber is a thin strip, the main features are: the middle section of steel fiber is linear, at both ends of the steel fibers have an upward tilt of the end of the hook, respectively. On the surface of both ends of the upturned end of the hook in the same horizontal plane, the ends were curled up under the surface of the end of the hook in the same horizontal plane. On the surface of both ends of the upturned end of the hook is higher than the upper surface of the middle section of the steel fibers, both ends of the lower surface of the upward tilt of the end of the hook is higher than the lower surface of the middle section of the steel fibers. Experiments show that the use of the utility model of steel fiber reinforced concrete, compressive strength, flexural strength early crack were increased by more than 27%, while the ultimate flexural strength increased by 67.7%, a 92.6% increase splitting tensile strength, resistance shear strength increased 101.6%.

- Q: What is the process of manufacturing steel products?

- The process of manufacturing steel products involves several steps. It typically begins with the extraction of iron ore, which is then refined and processed to remove impurities. The refined iron ore is then melted in a blast furnace, along with other materials such as limestone and coke, to produce molten iron. This molten iron is further processed in a basic oxygen furnace or an electric arc furnace to remove impurities and adjust its composition. The resulting molten steel is then cast into various shapes through processes like continuous casting or ingot casting. The cast steel is then further processed through rolling, forging, or other forming methods to shape it into the desired final product. Finally, the steel product undergoes heat treatment, surface treatment, and quality control measures to ensure its strength, durability, and desired properties.

- Q: How do steel products contribute to the transportation and logistics sector?

- Steel products contribute to the transportation and logistics sector in multiple ways. Firstly, steel is used extensively in the manufacturing of vehicles, including cars, trucks, trains, and ships. Its high strength-to-weight ratio and durability make it an ideal material for constructing vehicle bodies, chassis, and components, ensuring safety and reliability in transportation. Moreover, steel is crucial in the construction of infrastructure necessary for transportation and logistics, such as bridges, tunnels, railway tracks, and port facilities. These structures require the strength and resilience of steel to handle heavy loads, withstand harsh environmental conditions, and provide efficient and safe transport routes. Additionally, steel plays a significant role in the production of shipping containers, which are essential for the movement and storage of goods globally. These containers are made from steel to withstand stacking, handling, and transportation while protecting the goods inside. Steel's strength and corrosion resistance make it an ideal material for these purposes. Overall, the use of steel products in the transportation and logistics sector ensures the efficiency, reliability, and safety of various modes of transportation, infrastructure, and storage, contributing to the smooth functioning of global supply chains and facilitating economic growth.

- Q: How is steel used in the production of textile machinery?

- Steel is used in the production of textile machinery for various purposes such as constructing the machine frame, gears, and shafts, as well as providing structural support and durability to handle the heavy loads and high speeds involved in textile manufacturing processes.

- Q: How is steel used in the construction of warehouses and storage facilities?

- Steel is commonly used in the construction of warehouses and storage facilities due to its strength and durability. It is used for the framework and support structures, as well as for roofing and siding. Steel provides a secure and reliable structure that can withstand heavy loads and harsh weather conditions, making it ideal for these types of buildings.

- Q: How do steel products contribute to the defense and military sector?

- Steel products contribute to the defense and military sector in various ways. Firstly, steel is a key material used in the manufacturing of military vehicles and equipment, such as tanks, armored vehicles, and submarines, providing them with the necessary strength and durability to withstand harsh environments and combat situations. Additionally, steel is used in the construction of military infrastructure, including barracks, hangars, and command centers, ensuring their sturdiness and resilience. Moreover, steel plays a crucial role in the production of weaponry, such as firearms, missiles, and artillery, as it can withstand high temperatures and pressures required for their operation. Overall, steel products are indispensable in the defense and military sector, ensuring the reliability and effectiveness of equipment and structures critical for national security.

- Q: What are the different types of steel wires and their applications in telecommunications?

- There are several types of steel wires commonly used in telecommunications. These include galvanized steel wires, stainless steel wires, and high-tensile steel wires. Galvanized steel wires are coated with a layer of zinc, which provides corrosion resistance and durability. They are commonly used for overhead transmission lines, telephone cables, and fiber optic cables. Stainless steel wires are highly resistant to corrosion and have excellent strength properties. They are often used in marine environments, underground installations, and for aerial cables where high tensile strength is required. High-tensile steel wires are known for their exceptional strength and toughness. They are used in applications where heavy loads and long spans are involved, such as suspension cables for bridges and power transmission lines. Overall, these different types of steel wires play a crucial role in the telecommunications industry by providing strength, durability, and reliability for transmitting signals and supporting communication infrastructure.

- Q: How does steel pipe threading for fire sprinkler systems work?

- Steel pipe threading for fire sprinkler systems involves the process of cutting threads onto the ends of steel pipes to create a tight and secure connection between the pipes and fittings. This threading allows for the easy installation and assembly of the fire sprinkler system components, ensuring a reliable and leak-free system.

- Q: How is steel used in the construction of pre-engineered buildings?

- Steel is used extensively in the construction of pre-engineered buildings as it offers excellent strength, durability, and versatility. It is used for the primary structural components such as columns, beams, and roof trusses, providing a strong framework for the entire building. Additionally, steel panels are commonly used for the walls and roof, ensuring a sturdy and weather-resistant enclosure. Overall, steel's high strength-to-weight ratio and ability to be easily fabricated make it an ideal material for pre-engineered building construction.

- Q: How are steel products tested and certified for quality and performance?

- Steel products are tested and certified for quality and performance through a rigorous process that involves various stages. Initially, the raw materials used for manufacturing the steel are thoroughly inspected to ensure they meet the required specifications. Then, during the production phase, multiple tests are conducted, including tensile and hardness tests, to assess the strength and durability of the steel. Additionally, non-destructive testing methods such as ultrasonic examination and magnetic particle inspection are employed to identify any potential defects or flaws. Finally, the finished steel products undergo quality control measures, where samples are randomly selected and tested to verify their compliance with industry standards and regulations. Once the products successfully pass these tests and meet the necessary criteria, they are certified for quality and performance, ensuring that they meet the required specifications and can perform reliably in their intended applications.

- Q: What are the different types of steel meshes and their uses?

- There are several different types of steel meshes, each with their own specific uses. Some common types include welded wire mesh, expanded metal mesh, and woven wire mesh. Welded wire mesh is made by welding intersecting wires together, and it is commonly used in construction, fencing, and agriculture. Expanded metal mesh is created by cutting and stretching a sheet of metal, resulting in a diamond-shaped pattern. It is often utilized for grating, walkways, and security applications. Woven wire mesh is made by weaving individual wires together in a crisscross pattern, and it finds application in filters, screens, and decorative purposes. These are just a few examples, but steel meshes are versatile and can be tailored to meet various needs across industries.

Send your message to us

Cold drawn carbon fiber cut-off

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords