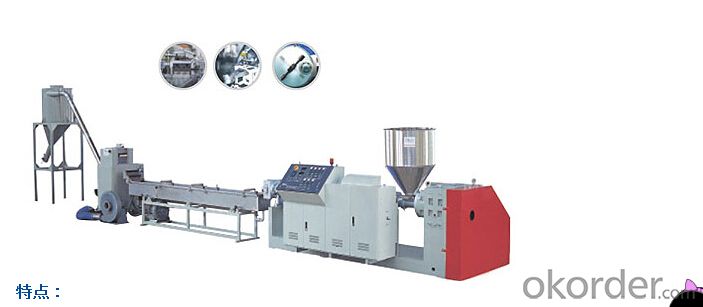

CMAX Serious Single Screw Pelletizing Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

waste plastic pelletizing line

is used to pelletize waste PP,PE film, etc.

With capacity from 18-1200kg/h.

plastic pelletizerwaste plastic pelletizing line

is used to pelletize waste PP,PE film, etc.

With capacity from 18-1200kg/h.

plastic pelletizerwaste plastic pelletizing line

is used to pelletize waste PP,PE film, etc.

1.This pelletizing extruder has the special screw design and different configuration, it is suitable for the recycling and pelletizing of raw materials such as PP, PE, PET, PS, ABS, PA, PVC, PC, POM, EVA, PMMA and the pelletizing of the raw materials with different colors.

2.The gearbox is high torque designed which attains the functions of low noise and stable operation. Surface of the screw and barrel has been special treated so that the screw and barrel are wearable, they can have a very plastification and mixing effect and the production capacity is high.

3. The extruder has the vacuum vented design which exhaust the vapor or gas during the production, so that the output can be more stable and the pellets are more dense.

Technical paramete

Model | Screw dia.(mm) | L/D | Screw speed (rpm) | power of main motor(kw) | Output(Kg/h) |

CAMX-45 | 45 | 25-34 | 20-120 | 5.5-11 | 18-40 |

CAMX-65 | 65 | 25-34 | 20-120 | 15-37 | 40-90 |

CAMX-90 | 90 | 25-34 | 20-95 | 37-75 | 100-300 |

CAMX-120 | 120 | 25-34 | 20-80 | 55-110 | 250-350 |

CAMX-150 | 150 | 25-34 | 20-80 | 110-160 | 300-600 |

CAMX-180 | 180 | 25-35 | 20-70 | 180-250 | 400-850 |

CAMX-200 | 200 | 30-35 | 20-60 | 220-280 | 600-1200 |

Product show

Our Services

Packaging & Shipping

FAQ:

1.What will be your end products?(cat/dog/fish feed?)

2.What capacity do you require?(How many tons/h)

3.Do you need a single machine or the whole line?

4.Do you need Computer automatic batching system?

1.The MOQ: one set/sets.

2.Payment terms is T/T

3.Delivery time is 1~3 month

4.The Prot:Shanghai in China.

5.Shipping Terms: FOB

- Q: Comparison of swing granulator, high-speed granulator, one-step granulator difference?

- General plastic and water will degrade the performance of plastic degradation will make significant decline, affect the product performance, so the new material is generally not wet, extrusion is to make the plastic particle drying.

- Q: Is environmental protection approved for plastic granulation?

- According to the provisions of the "construction project environmental impact assessment classification management directory", plastic products manufacturing in artificial leather, foam rubber involving toxic materials; a plating process requires the preparation of the EIA report; the rest of the need for the preparation of the EIA report table.

- Q: What's the fabric of the plastic bread machine?! What's in the cloth?

- The plastic granulator is made of glass fiber cloth, which plays an insulating role. Inside the cloth is an electric heating wire used to heat the barrel and melt the plastic.

- Q: How much will it cost to invest in the recycled plastic particle production line?

- 4. more efficient cutting and compacting machine to ensure high output of granulator equipment and low energy consumption.5., from Europe's leading design of dehydration machines and vibrating screen, greatly reducing the energy consumption of equipment,And improve the efficiency of granulator equipment.6., the new granulator has: reasonable configuration, smooth operation, low noise, energy saving, high yield and so on7. certification of CE and ISO9001 professional organizations.

- Q: how much the price, I hope to know a friend told me Oh, thank you ah!

- We have been committed to the research and development of plastic extrusion machinery technology, the market for plastic extruder universal low productivity and short service life, high power consumption, in the mechanical design, according to the needs of different customers and different raw materials, developed separation screw, high mixing screw, machine tube technology KIV and with the use of hard tooth, mute type reducer, effectively solve these problems, the effective capacity of extruder with same specification and same type of plastic will increase from 20% to 30%, the actual power consumption is reduced by about 20%, the real implementation of the high capacity, long service life and low power consumption.In some developed countries, foreign enterprises and joint ventures on the type of environmental protection requirements, including noise control, exhaust gas treatment, closed the smoke, dust, and different frequency voltage, motor, we can achieve the design and manufacturing requirements.We follow the requirements of ISO9001 quality control system, establish a complete and standardized internal technical standards and quality control procedures, control point from the whole process of pre-sales service to product design, manufacturing, customer service service, to create a full range of its product quality, we have a number of years engaged in plastic granulator research and development, manufacturing and service a professional engineering team and staff, provide a solid guarantee for the customer confidence.

- Q: The difference between the whole machine, granulating machine, granulating machine of the three English translation?

- The granulator is a kind of forming machine which can make material into a specific shape. Widely used in chemical, petrochemical, pharmaceutical, food, building materials, mining and metallurgy, environmental protection, printing and dyeing, ceramics, rubber, plastics and other fields. According to the structure and working principle and divided into CF type rotary belt type condensing granulator flat twin screw extruder drying drum roll production machine dry granulating machine (referred to as the roll granulator granulator) on tooth disc vacuum condensation granulator. The granulating mechanism has the advantages of quick granulation and good effect. The filter screen for designing special holes is carefully screened, and the friction filter rod can crush, sieve and filter the solid particles, and is widely used in the pharmaceutical, chemical and food industries. Instead of swing granulator, the utility model is a new generation of granular equipment.

- Q: Dry granulator and wet granulation machine what is the difference

- General plastic and water will degrade the performance of plastic degradation will make significant decline, affect the product performance, so the new material is generally not wet, extrusion is to make the plastic particle drying.

- Q: What plastic particles are used for wire injection? How much would you like to invest in a plastic pelleting plant?

- Wire is generally used PVC majority, there are some cable, fiber cable with HDPE, LDPE, EVA and so on.

- Q: How can the granulator recycle the plastic bottle?

- Well, what is the sorting process of the plastic granulator?A typical process in which the discarded bottles will be sorted first on the basis of color and size sometimes. Once sorted, they need to be washed away; however, the washing machine, while in a piece, is not the most advantageous way. Therefore, to facilitate the washing process, the bottle is likely to be broken down into small pieces. Plastic granulator, plastic grinding machine can be used to do work, such as Jordan to reduce the manufacture of solutions. They let a shredder break down into smaller sizes and then send it to the cleaning station for a wide variety of plastic and PET containers. Check out some plastic crush videos. Once the bottle is torn and a suitable size is washed, they are not yet ready for processing into other goods.

- Q: How to solve the noise of plastic granulator

- Change the mute hob cutter or water ring pelletizer.

Send your message to us

CMAX Serious Single Screw Pelletizing Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches