CMAX FLEXITANK FOR LIQUID TRANSPORTATION -A grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 7000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX offers safe, efficient, cost-effective bulk liquid logistics transportation service with CMAX flexitank, which is the most reliable and safe flexitank solution available; lowering your risk, costs and environmental impact.

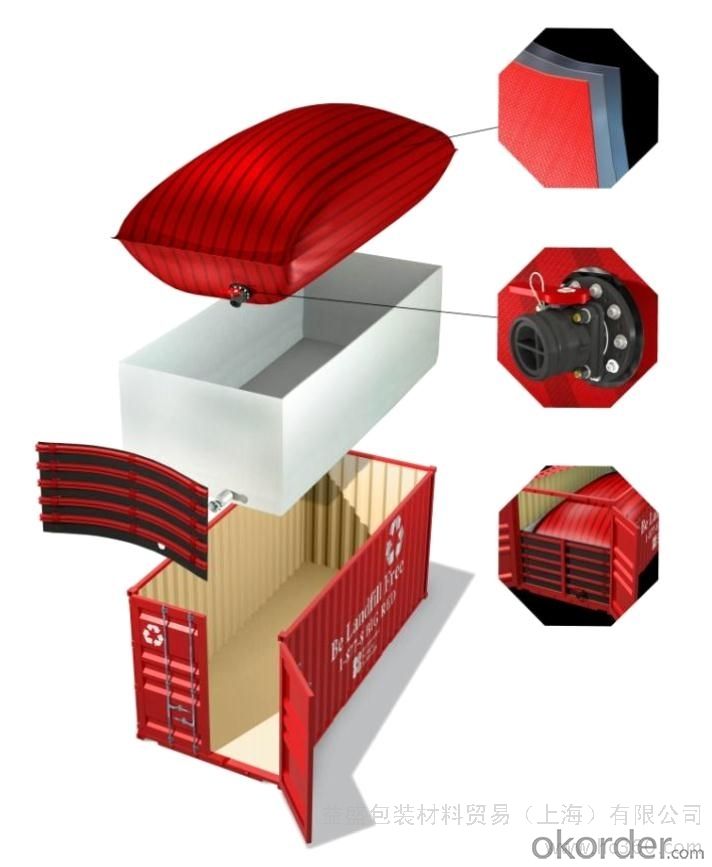

A CMAX flexitank transforms a standard 20’ ISO container into a non-hazardous bulk liquid transportation system. Designed specifically to ensure your bulk liquid cargo arrives safely and in optimum condition, CMAX flexitank incorporates the very latest barrier technology materials to protect your product from contamination during transit.

CMAX Flexitank System Features and Properties:

u Made from 100% clear virgin polyethylene materials. Fully compliant with FDA and EU Regulatory Food Contact regulations. Contains no carbon black.

2.Safe and Reliable

u Strengthen the inner bag with high-tensile purpose durable one-piece tubular polypropylene woven fabric that provides intensive protection to the liquid cargo loaded within the inner bag.

u Mechanical heavy steel constructed bulkhead system is designed for double protection to liquid cargo within the container, with which a container loaded with 24,000L liquid flexitank has been witnessed safely passed the COA Railway Impact Test done at AAR( TTCI). , in which the container received 2 times huge impacts at the running speed of 6mph.

u CMAX flexitank system is fully COA compliant in accordance with the latest edition of the COA Flexitank Code of Practice. All impact testing g was witnessed, verified and certificated by Lloyds Register.

u The specially designed cam lock male valve with anti-suction pad allows efficient discharging without human labor with small volume cargo residue.

4.24-hour Global Service

u Offer services including container preparation, flexitank fitting, cargo loading supervision, inland and maritime transportation, flexitank discharging, disposal and recycling via global network covering 5 continentals, 80 main ports via CMAX offices and 36 agents around the globe.

u 24-hour public service line offers instant communication and action upon request around the world.

5.Eco-environmental

u All polyethylene, polypropylene, steel materials used are fully recyclable, all are environmental friendly.

6.Cost-effective

u Compared to ISO Tank, no cleaning cost, no returning cost.

u Load 30% more than with drums per 20ft container

u Save 50%+ package positioning cost than with drums per 20ft container

- Q: How many tons can a large container hold in one container?

- Usually around 20 tons, but because of the different ship companies, the requirements are also different.20 feet of cabinets: product is 5.90x2.34x2.38 meters, distribution is generally 17.5 tons gross weight, the volume of 24-26 cubic meters.40 feet of cabinets: product is 11.95x2.34x2.38 meters, distribution is generally 22 tons gross weight, volume of 54 cubic meters.The 40 foot high cabinets: product is 11.95x2.34x2.68 meters. Distribution is generally 22 tons gross weight, volume of 68 cubic meters.

- Q: What reason is the container loaded?

- General cargo loading will appear this kind of circumstance, such as steel, if both sides of the wall without box wood pad, finished goods or packing process, it is easy to cause the box wall on both sides of the outer drum.

- Q: Do container liquids transport oil? What do you need to pay attention to?

- 1. capacity up to 25000 liters. 2. product supply and product quality are subject to considerable control and supervision. 3. using the latest polyethylene sealing technology, advanced well documented. 4. no pollution, no cleaning, ozone sterilization should be customer requirements, the implementation of aseptic packaging. 5. all containers are designed in one way with the highest level of environmental responsibility. 6. realize the door-to-door transportation of liquid products, reduce the loading and unloading process, reduce the workload of loading and unloading, and save labor costs. The unique design of the 7. special positions, can be reduced (or even eliminate) liquid products in the transport process of drip and leakage or damage to packing phenomenon, reduce the damage or loss. 8. liquid container raw materials are in line with environmental protection requirements, even if discarded, it will not cause any pollution to the environment, but also can be cleaned, recycled and re used in agriculture or other industries.

- Q: What brand of container liquid bag is good? How to lead the liquid bag?

- Qualification: through the China National entry-exit inspection and Quarantine Center Laboratory, according to the GB/T5009.60-2003 standard for testing, product hygiene to meet the GB9687-88 standard requirements, suitable for the export of food. The liquid bag meets the American FDA standard and can safely store and transport food grade goods;

- Q: What kind of containers do you have for transporting petrochemical products?

- Then fill the bag directly with liquid

- Q: How can rubber oil be removed from container liquid containers?

- If the winter is too sticky, steam or steam the bottom of the load and pump it out

- Q: What about liquid bag container shipping?

- BULKHEAD can be installed in the liquid bag, equal to an incubator, and its maximum temperature is 80 degrees. This liquid, which has a temperature requirement, is very good. It can heat up these special liquids. This is a traditional pot can not do.

- Q: What is the container fluid bag? What's the use of it?

- Container liquid bag is a new type of liquid transportation, which has more advantages than tank car.

- Q: Brief introduction of container liquid bag

- The maximum capacity of up to 24000 liters of bottled is about 35% higher than the container freight to calculate, tank, special container freight pay only one-way freight, no empty container return freight and cleaning cost, and can effectively avoid the cross contamination of goods reduces handling, packaging and materials management etc. the cost of compliance with environmental and food packaging requirements the product of raw materials, no pollution, suitable for ocean transportation, railway transportation and other modes of transport on the environment.

- Q: How long will it take before the container is changed? The box? Which department manages the container terminal?

- The conventional 20 TEU 40 TEUs respectively is 1.7T and 3.4T. The container belongs to each ship company, not to the quay. The port office is in charge of coordination when it is piled up at the dock.

Send your message to us

CMAX FLEXITANK FOR LIQUID TRANSPORTATION -A grade

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 7000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords