CHINESE HIGHT QUANLITY LOW CARBON FERRO CHROME WITH BEST PRICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

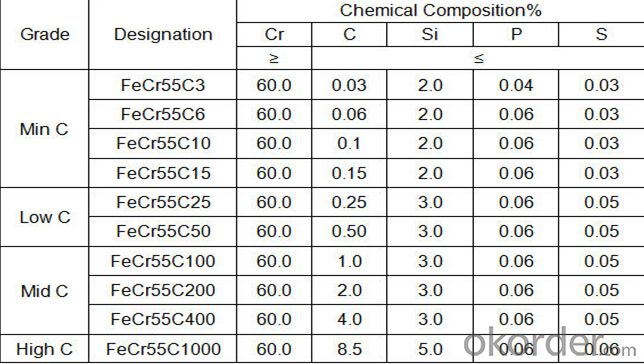

Specifications

Low Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: What is the difference between them?From hardness, abrasion resistance analysis!

- Is the use of metal carbide hard alloy with high heat resistance and high wear resistance (WC tungsten carbide, titanium carbide, tantalum niobium carbide TiC TaC, NbC etc.) and metal binder (cobalt, nickel and molybdenum) powder metallurgy products under high temperature sintering. Its hardness is 93 HRA8, high temperature resistance of 850 ~ 1000 C, has good abrasion resistance, allowing the use of the cutting speed can reach 100 ~ 300m / min, can be a variety of materials including machining hardened steel, hard alloy is commonly used tungsten cobalt (YG), tungsten titanium cobalt (YT) and general hard alloy (YW) three.Diamond is an allotrope of carbon, natural diamond and diamond two.

- Q: What are the features of cemented carbide YG8 knives?

- Density: 14.6-14.8; hardness HRA:90.5; flexural strength, Mpa2300High bending strength, shock resistance and vibration resistance is better than YG6. It is suitable for low speed rough machining of cast iron, non-ferrous metals and their alloys, and non-metallic materials

- Q: Carbide cutting insert

- Brand in general can be found above, but you can also go to Zhuzhou tungsten tungsten alloy to see, they have good quality there

- Q: There are three kinds of cemented carbides, of which tungsten, cobalt and titanium are brittle cemented carbides?

- [classification of cemented carbide] ISO carbide carbide cutting into 3 categories: P, K and M.1, P class (equivalent to China's YT class) cemented carbide by WC, TiC, and Co composition, also known as tungsten titanium cobalt carbide. This kind of alloy is mainly used for processing steel materials. Common brands are YT5 (mass fraction of TiC is 5%), YT15 (mass fraction of TiC is 15%), with the mass fraction of TiC increased, the mass fraction of cobalt decreased, hardness and wear resistance increased, bending strength decreased. This kind of hard alloy is not suitable for processing stainless steel and titanium alloy.2, K class (equivalent to China's YG class), carbide composed of WC and Co, also known as tungsten cobalt carbide. These alloys are mainly used to process cast iron, nonferrous metals and their alloys. The common grades are TG6 (cobalt mass fraction 6%) and YG8 (cobalt mass fraction 8%). As the mass fraction of cobalt increases, the hardness and wear resistance decrease, and the flexural strength and toughness increase.3, M class (equivalent to China's YW class), carbide is based on WC, TiC, Co, and then added TaC (or NbC) and into. After the addition of TaC (or NbC), the comprehensive properties of cemented carbide were improved. Such cemented carbide can be used for both cast iron and non-ferrous metals, as well as for steel and for high temperature machining

- Q: We'll drill on the stainless steel column. Which bit is better?

- High cutting force and high cutting temperatureThis kind of material has high strength, large tangential stress and large plastic deformation during cutting, so it has great cutting force. In addition, the material has a poor thermal conductivity, which results in the increase of cutting temperature, and the high temperature often concentrates in the long and narrow area near the cutting edge of the tool, thus speeding up the tool wear.Serious work hardeningAustenitic stainless steel and some high alloy stainless steel is austenite, high work hardening tendency when cutting, usually plain carbon steel several times, the tool in hardening region cutting, shortening tool life.Easy to stick the knifeBoth austenitic stainless steel and martensitic stainless steel exist in the process of chip toughness, cutting temperature is very high. When the tough chip flows through the rake face, the bonding, welding and other sticking phenomena will occur, which will affect the surface roughness of the machined parts. ??Tool wear acceleratedThe materials generally contain high melting point elements, large plasticity, high cutting temperature, so that the tool wear faster, sharpening and changing knives frequently, thus affecting the production efficiency and improving the tool cost.Mainly to reduce the cutting line speed, feed. With special processing stainless steel or high temperature alloy cutting tools, drilling, tapping the best internal cooling

- Q: What kind of grinding wheel is the most suitable for carbide tools?. My existing grinder, 2800 rpm, /s wheel diameter, can hold 250mm. Please help answer.

- Green silicon carbide particle size 60-80, coarse grinding fine grinding. Sharpening bar with white corundum

- Q: What are the types of cemented carbides?

- 5, industry special cutter category, including auto industry special knife, mobilization machine, industry special knife, sewing machine industry special knife, die industry special knife, textile machine special knife and printed circuit board industry special knife.Hard alloy tool with cemented carbide and carbon steel bar welded, it is characterized with high hardness, wear resistance and heat resistance of hard alloy blades are made of high abrasion resistance and high heat resistance WC (tungsten carbide), TiC (Tan Huatai), TaC (TAC) and Co (cobalt) powder after high temperature sintering.Different cemented carbide is suitable for different purposes, so you can refer to the following, I hope you can help!

- Q: The difference between cemented carbide and tungsten.

- The market is usually called tungsten carbide, the two are the same, and the high speed steel called high speed steel. This is the old habit of name of state owned enterprises.

- Q: What does P stand for and what is 30? What are its advantages and disadvantages? What is suitable for processing?

- Cemented carbides are classified into 3 categories, and the ISO standards are defined as K, P, and m three. Each corresponds to the YG class, the YT class, and the YW class in our country. The material properties of P30 correspond roughly to the performance of our brand YT5. Suitable for carbon and alloy steels. But it is not suitable for machining titanium alloy or brittle material, because this kind of cemented carbide with high hardness, good wear resistance, but the strength is not enough, cutting the material easily.

- Q: Why carbide fracture?

- First you have to choose the right material. Various uses must choose the relative grade, and also has the material which you use, has the sundry inside

Send your message to us

CHINESE HIGHT QUANLITY LOW CARBON FERRO CHROME WITH BEST PRICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches