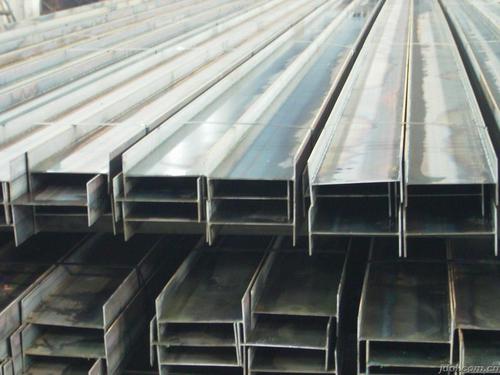

CHANNEL ASTM A36 50MM-300MM OR JIS U CHANNEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality CHANNEL ASTM A36 50MM-300MM OR JIS U CHANNELat great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1.The JIS U Channel Steel can be devided into two kinds, namely common channel steel and light channel steel. The sizes of hot rolled common channel steel range from 5# to 40#. Meanwhile, the channel steel can be divided into cold forming sectional equal channel steel, cold forming sectional unequal channel steel, cold forming inner edge channel steel and outer edge channel steel.

2.The JIS u channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. The channel steel with sizes under 14# is usually applied to construction engineering, as purline, while the channel steel with sizes above 16# is more likely to be used in building vehicle chassis structure and mechanical structure. Furthermore, the channel steel in sizes above 30# are target at building bridge structure, as tension bar.

3.In a word, the channel steel must possess perfect welding property, riveting property and mechanical property and so on.

Product Advantages:

OKorder's CHANNEL ASTM A36 50MM-300MM OR JIS U CHANNELare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Original Place | Tangshan, China | Brand Name | UINDA |

Standard | JIS G3192 : 1990 | ||

Material Grade | SS490 | ||

Sizes | 50mm to 200mm | ||

Sales Volume/Year | 3000MT | ||

Destination Area | Middle East, Africa, Southeast Asia | ||

2. The sections in details are as followings in the table-1

JIS U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

| (mm) | (mm) | (mm) | (mm) |

|

50x25 | 50 | 25 | 3.0 | 6.00 | 2.37 |

75X40 | 75 | 40 | 3.8 | 7.00 | 5.30 |

75X40 | 75 | 40 | 4.0 | 7.00 | 5.60 |

75X40 | 75 | 40 | 4.5 | 7.00 | 5.85 |

75X40 | 75 | 40 | 5.0 | 7.00 | 6.92 |

|

|

|

|

|

|

100X50 | 100 | 50 | 3.8 | 6.00 | 7.30 |

100X50 | 100 | 50 | 4.2 | 6.00 | 8.03 |

100X50 | 100 | 50 | 4.5 | 7.50 | 8.97 |

100X50 | 100 | 50 | 5.0 | 7.50 | 9.36 |

|

|

|

|

|

|

125X65 | 125 | 65 | 5.2 | 6.80 | 11.66 |

125X65 | 125 | 65 | 5.3 | 6.80 | 12.17 |

125X65 | 125 | 65 | 5.5 | 8.00 | 12.91 |

125X65 | 125 | 65 | 6.0 | 8.00 | 13.40 |

|

|

|

|

|

|

150x75 | 150 | 75 | 5.5 | 7.30 | 14.66 |

150x75 | 150 | 75 | 5.7 | 10.00 | 16.71 |

150x75 | 150 | 75 | 6.0 | 10.00 | 17.90 |

150x75 | 150 | 75 | 6.5 | 10.00 | 18.60 |

150x75 | 150 | 75 | 6.5 | 10.00 | 24.00 |

|

|

|

|

|

|

200X80 | 200 | 80 | 7.5 | 11.00 | 24.60 |

3. The mechanical property of JIS U Channel Steel in the table-2:

Grade | Yield Strength,N/mm² | Extension Strength N/mm² | |||

Thickness of Steel,mm | |||||

≦16 | >16-≦40 | >40-≦100 | >100 | ||

SS490 | ≧285 | ≧275 | ≧255 | ≧245 | 490-610 |

4. The chemical composition of JIS U Channel Steel as per SS490 in the table-3

Grade | Element(%) | |||

C | Mn | P | S | |

SS490 | - | - | ≦0.050 | ≦0.050 |

FAQ:

Q1 What makes stainless steel stainless?

A1 Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2 What makes stainless steel stainless?

A2 Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Are steel channels suitable for electrical conduit systems?

- Certainly, electrical conduit systems can be well-suited for steel channels. The strength and durability of steel channels make them perfect for offering support and safeguarding electrical wiring. They excel at directing and arranging electrical cables within a building or structure. Furthermore, steel channels exhibit resilience in unfavorable environmental conditions, such as extreme temperatures or moisture exposure, contributing to their appropriateness for electrical conduit systems. Nevertheless, ensuring proper grounding and insulation of the steel channels is vital to avoid any electrical risks or interference.

- Q: In the steel structure of steel purlin 160*60*20*2.5 is what mean

- Stands for 160mm height, 60mm width, and 2.5mm thickness, and 20mm is the size of two small ears.

- Q: What are the weight-bearing capacities of steel channels?

- The weight-bearing capacities of steel channels vary depending on several factors including the dimensions and design of the channel, the grade of steel used, and the specific loading conditions. Steel channels are commonly used in construction and structural applications for their strength and durability. To determine the weight-bearing capacity of a steel channel, engineers typically calculate the maximum load it can support without experiencing failure or deformation. This calculation is based on various mechanical properties of the steel, such as its yield strength, ultimate tensile strength, and section modulus. Yield strength refers to the maximum stress a material can withstand without permanent deformation, while ultimate tensile strength indicates the maximum stress it can handle before breaking. Section modulus, on the other hand, measures the resistance of a cross-sectional shape to bending and is essential for determining the load-carrying capacity of a steel channel. To obtain specific weight-bearing capacities, it is necessary to consult engineering design tables, manufacturer specifications, or consult with a structural engineer. These resources provide detailed information on the weight-bearing capacities of different steel channel sizes and shapes based on their design, material properties, and intended usage. In conclusion, the weight-bearing capacities of steel channels depend on various factors and can only be accurately determined through engineering calculations, referencing design tables, or consulting with professionals in the field of structural engineering.

- Q: Large steel channel used for steel structural staircases

- If not sure, can see 15j401 Gangti atlas. Choosing proper channel steel can not only ensure the structural safety, but also achieve the goal of saving the cost! Hope to help you!

- Q: Is section steel the same as channel steel?

- Channel steel is one of the types of steel, including channel steel, angle steel, I-beam, H steel, L steel, etc..

- Q: Overhanging Scaffold; channel spacing

- Placement of the cantilever beam, welding rod base, since the corner in order to both sides of the bottom vertical pole, bottom and vertical sweeping bar buckle is fixed, installed in the horizontal sweep shot, and is fixed with a vertical rod, each side up 3--4 pole, then installed the first step (longitudinal flat bar and the vertical and lateral buckling) fixed flat bar (a small bar, near the pole and longitudinal vertical rod fastening fixed). To correct the vertical and horizontal lever of the upright pole to meet the requirements, tighten the fastening bolts according to the 45--55N & M force to form the initial section of the frame, and then extend forward in accordance with the above requirements until the first step of the rack is completed. After crossing the circle, the quality of the structure shall be thoroughly checked, and the design requirements and the quality of the frame shall be strictly ensured. The end wall parts shall be provided, and the second and third steps shall be erected according to the operation procedures and requirements of the first step...... In accordance with the erection process and the fashion set, the wall piece and the scissors support are provided with a work layer, a cross bar, a foot board and a work layer railing, a foot blocking board and a close mesh net.

- Q: What are the maximum lengths available for steel channels?

- The manufacturer and the specific type of steel channel in use can cause variations in the maximum lengths available. Generally, standard lengths span from 20 to 40 feet, although some manufacturers may provide longer options, exceeding 60 feet, based on project requirements and equipment capacity. Consulting the manufacturer or supplier is crucial to ascertain the available lengths suitable for the specific steel channel under consideration.

- Q: Are steel channels suitable for residential construction?

- Yes, steel channels can be suitable for residential construction. Steel channels, also known as C-channels or U-channels, are often used in construction for their strength and durability. They are commonly used as structural components in framing systems, providing support and stability to the building. Steel channels have several advantages that make them suitable for residential construction. Firstly, they have a high strength-to-weight ratio, meaning they can support heavy loads while being relatively lightweight. This makes them ideal for constructing floors, walls, and roofs in residential buildings. Furthermore, steel channels are highly resistant to fire, termites, and other pests, which can be concerns in residential areas. They do not warp, rot, or decay like other materials such as wood, ensuring a longer lifespan for the building. In addition, steel channels can be easily fabricated and installed, which helps streamline the construction process. They can be cut to the desired length and shape, allowing for flexibility in design. Moreover, they can be easily connected and welded, ensuring strong connections and reducing the risk of structural failures. Lastly, steel channels are cost-effective in the long run. Although they may have a higher initial cost compared to some other materials, their durability and low maintenance requirements result in reduced repair and replacement costs over time. However, it is important to consider the specific requirements and regulations of the residential construction project, as well as consulting with professionals, such as architects and engineers, to ensure that steel channels are suitable for the specific application.

- Q: What are the aesthetic options for steel channels?

- There are several aesthetic options available for steel channels, including different finishes such as polished, brushed, or painted surfaces. Additionally, steel channels can be customized with decorative patterns, textures, or etchings, providing further aesthetic choices.

- Q: Can steel channels be used in the chemical manufacturing industry?

- Yes, steel channels can be used in the chemical manufacturing industry. Steel channels provide structural support and can be used in various applications such as building chemical storage tanks, platforms, walkways, and support structures for equipment and piping systems. Steel is known for its durability, strength, and corrosion resistance, making it suitable for chemical environments where exposure to corrosive substances and high temperatures is common. Additionally, steel channels can be customized and fabricated to meet specific design requirements, offering flexibility in construction and installation. Overall, steel channels are a reliable and versatile choice for the chemical manufacturing industry.

Send your message to us

CHANNEL ASTM A36 50MM-300MM OR JIS U CHANNEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords