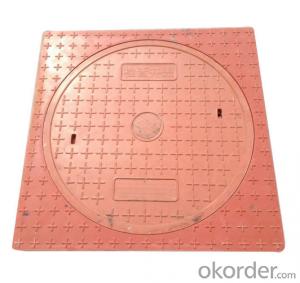

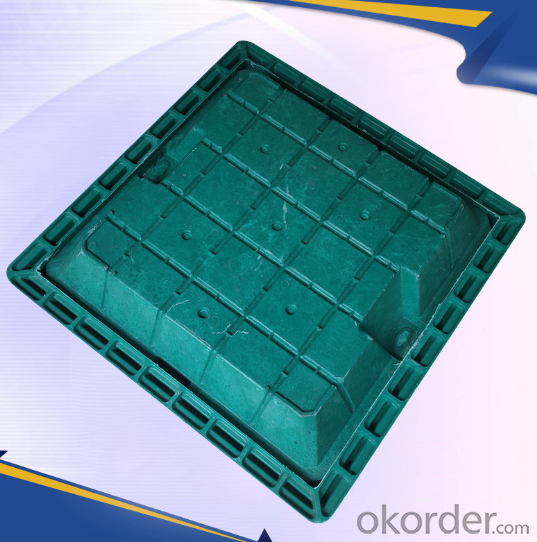

Casted Ductile Iron Manhole Covers B125 and D400 for industry with Competitive Prices Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1) production standard: EN124 from A15 to F900

2) Material: grey iron, ductile iron

3) Type: round type and Square type, triangle

4)Standard:ISO9001,EN124

5)Applicable medium:gases,liquids,steam

Specification

| Item No. | Class | Clear Opening(mm) | Frame Size(mm) | Frame Height(mm) | Unit Weight (kg/set) |

| PBC700 | B125 | 600×600 | 700×700 | 40 | 37 |

Advantages

Good compressive, water-proof, anti-corrosion, not rust, long service life (at least 30 years).

The quality meets the same kinds cast ion manhole covers but the cost is 30% lower than other suppliers.

Packaging & Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

FAQ

1.Can I request to advance the shipment?

A: It should be depends on whether there is sufficient inventory in our warehouse.

2.Can I have my own Logo on the product?

A: Yes, you can send us your drawing and we can make your logo, but you have to bear their own the cost.

- Q: There is a little trace of polishingShock polishing is even worseElectrolysis can not be uneven, there is a slight bump

- German winter three step mirror polishing 2013 new processYou can free proofing!

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Especially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: How do casting parts remove stress?

- Annealing treatment, according to different casting annealing treatment, eliminate thermal stress, if need to restore hardness or increase hardness, and then quenching treatment

- Q: What is the reason for 304 stainless steel precision casting parts to be changed?

- Steel deformation control is one of the most common problems in the metal processing industry. Any process will occur. The casting is the largest deformation and the least fine. It is generally used to produce blank blanks

- Q: How can the casting be plated with ordinary zinc plating? The coating is too thin and requires 0.08 thickness

- Hot galvanizing doesn't seem to workThe zinc layer is 275g/ square meters of material coating is 0.019mm (mm), up to 0.08 thick.

- Q: Why should pig iron be used in casting?

- Popular name is called pig iron, in fact, is a kind of cast iron without treatment, after casting, in iron elements to add other elements to improve casting performanceIt mainly improves the fluidity, reduces the melting point and reduces the shrinkage.Usually pure iron and cast iron at the eutectic point (about 4.7% carbon content) can be used for castingThere are many kinds of cast iron, usually grey cast iron, ductile iron and vermicular graphite iron......

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Our country has a national standard for casting tolerance levels. This national standard applies to you in malleable iron, grey cast iron, and ductile iron.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

Send your message to us

Casted Ductile Iron Manhole Covers B125 and D400 for industry with Competitive Prices Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4166 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches