Carbon Steel Hot Rolled Wire Rod SAE1008

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Wire Rod at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Wire Rod are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Steel Grade: Q195/235, SAE1006-1018B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: in coil, coil weight around 2MT Alloy or Not: Alloy

Surface: round, no twisted, light and smooth Chemical Composition: (Please kindly find our chemistry of our material based on Q195、Q235A and Q235B as below for your information)

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Packaging & Delivery of Wire Rod SAE1008B:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

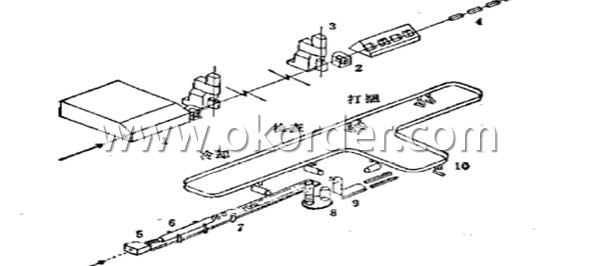

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the different decarburization testing methods for steel wire rod?

- Steel wire rod commonly undergoes various decarburization testing methods to determine the depth and extent of decarburization. These methods play a crucial role in assessing the quality and integrity of the steel wire rod. Below are different approaches utilized for decarburization testing: 1. Macro examination: A visual inspection of the steel wire rod's surface is conducted to identify signs of decarburization. The rod is cut, polished, and observed under a microscope to evaluate the depth and severity of decarburization. 2. Micro examination: Similar to macro examination, micro examination also involves inspecting the steel wire rod's surface under a microscope. This method provides a more detailed and magnified view, enabling a more accurate assessment of decarburization depth and extent. 3. Chemical analysis: By analyzing a sample of the steel wire rod's composition, chemical analysis can determine its carbon content. This data is then compared against desired specifications, with higher carbon content suggesting lower decarburization levels. 4. Hardness testing: Decarburization can affect the hardness of the steel wire rod. Hence, hardness testing measures the rod's resistance to indentation or penetration. A decrease in hardness may indicate the presence of decarburization. 5. Microhardness testing: This method measures the hardness of the steel wire rod using a smaller and more precise indenter. Microhardness testing offers a more accurate measurement of hardness and can detect the presence of decarburization. 6. Metallographic analysis: By preparing, polishing, and examining a sample of the steel wire rod under a microscope, metallographic analysis allows for the observation of the steel's microstructure and the presence of decarburization. Implementing a combination of these decarburization testing methods enables manufacturers to assess decarburization levels accurately. Consequently, appropriate measures can be taken to uphold the desired quality standards.

- Q: What are the major applications of low carbon steel wire rod?

- Low carbon steel wire rod has various major applications due to its versatility and characteristics. It is commonly used in the manufacturing of nails, screws, wire mesh, fencing, barbed wire, and other construction materials. Additionally, it is utilized in the production of automotive parts, such as springs and suspension components, as well as in the manufacturing of household appliances and electrical wires. Its affordability and strength make it a popular choice in numerous industries.

- Q: How is steel wire rod used in the manufacturing of wire nets?

- Steel wire rod is a crucial material in the manufacturing of wire nets due to its strength, durability, and flexibility. Wire nets are commonly used as fencing, mesh screens, and reinforcement in various industries such as construction, agriculture, mining, and transportation. To produce wire nets, steel wire rods are first subjected to a series of processes. Initially, the wire rods are carefully inspected for quality and conformity to specific standards. Then, they undergo a process called drawing, where the wire rod is pulled through a series of dies to reduce its diameter and increase its length. This drawing process enhances the wire's tensile strength and flexibility, making it ideal for use in wire nets. After drawing, the wire is further processed through annealing, a heat treatment that relieves internal stresses and improves its ductility. This step is crucial as it ensures that the wire is malleable enough to be woven or welded into various net configurations. Once the wire is ready, it is used to create wire meshes or nets by either weaving or welding methods. In the weaving process, the wire strands are interwoven in a crisscross pattern to form a grid-like structure. The wires can be woven in different patterns, such as plain weave, twill weave, or Dutch weave, depending on the desired strength and opening size of the wire net. Alternatively, the wire can be welded together at intersecting points to form a welded wire mesh. This process involves applying heat and pressure to join the wires, creating a sturdy and uniform net structure. Welded wire mesh is often preferred in applications that require higher strength and stability. Once the wire nets are manufactured, they can be used for a variety of purposes, such as fencing to secure perimeters, partitions to separate areas, or as protective barriers in industrial settings. The strength and durability of steel wire rods ensure that wire nets can withstand harsh environmental conditions, resist corrosion, and provide reliable performance over an extended period. In summary, steel wire rods play a crucial role in the manufacturing of wire nets. Their strength, durability, and flexibility make them suitable for weaving or welding into various net configurations. Wire nets find applications across different industries and provide solutions for fencing, mesh screens, and reinforcement needs.

- Q: What are the safety precautions to be followed while working with steel wire rod?

- To ensure the safety of yourself and others when working with steel wire rods, it is crucial to adhere to various safety measures. Below are some guidelines that should be observed: 1. Personal Protective Equipment (PPE): Always don appropriate PPE, including safety glasses, gloves, and steel-toed boots, in order to shield yourself from potential hazards. 2. Training and Knowledge: Make certain that you have received proper training and possess a solid understanding of the equipment, tools, and procedures involved in working with steel wire rods. 3. Secure Work Area: Maintain a clean and well-organized work area, free from any obstacles or tripping hazards that may lead to accidents. 4. Handling and Storage: Exercise caution when handling steel wire rods to prevent injuries. Utilize proper lifting techniques and equipment when lifting and carrying them. Store them in a designated area away from walkways to avoid accidental contact. 5. Inspection: Regularly inspect the wire rods for any signs of damage, such as sharp edges or protrusions, before and during use. Replace any defective rods immediately. 6. Fire Safety: During cutting or welding processes, steel wire rods can produce sparks. Ensure that the work area is devoid of flammable materials and have suitable fire extinguishing equipment readily accessible. 7. Cutting and Grinding: When cutting or grinding steel wire rods, employ appropriate tools and adhere to safety procedures. Wear a face shield or goggles to safeguard your eyes from flying debris. 8. Secure Fastening: Guarantee that the wire rods are securely fastened during installation or use to prevent them from becoming loose or falling. 9. Communication and Signage: Clearly communicate with individuals in the vicinity about the ongoing work. Utilize warning signs and barricades to prevent unauthorized access to the work area. 10. Emergency Preparedness: Familiarize yourself with emergency procedures and be aware of the location of emergency exits, first aid kits, and safety showers in the event of accidents or injuries. By adhering to these safety precautions, you can mitigate the risks associated with working with steel wire rods and foster a safer working environment for yourself and those around you.

- Q: What are the common machining methods for steel wire rod?

- The common machining methods for steel wire rod include cutting, bending, drawing, and threading.

- Q: What are the main factors affecting the market growth of steel wire rod?

- The main factors affecting the market growth of steel wire rod include demand from various industries such as construction, automotive, and manufacturing. Economic growth and infrastructure development also play a significant role. Additionally, raw material availability, technological advancements, and government policies related to trade and investment can impact the market growth of steel wire rod.

- Q: How is steel wire rod used in the production of suspension springs for automobiles?

- Steel wire rod is commonly used in the production of suspension springs for automobiles due to its high strength and durability. The wire rod is first straightened and then coiled into the desired shape and size to form the suspension spring. The coiled wire rod is then heat-treated to enhance its mechanical properties and make it more resistant to fatigue. This process ensures that the suspension spring can withstand the weight of the vehicle and provide a smooth and comfortable ride by absorbing shocks and vibrations from the road.

- Q: What are the different high-temperature properties of steel wire rod?

- Some of the different high-temperature properties of steel wire rod include high strength, good heat resistance, excellent oxidation resistance, and the ability to retain its shape and mechanical properties at elevated temperatures.

- Q: How is steel wire rod used in the manufacturing of wire rope assemblies for construction purposes?

- Steel wire rod is indispensable in the production of wire rope assemblies for construction purposes. These assemblies are widely employed in construction for a variety of uses, including lifting heavy loads, securing structures, and providing structural support. Steel wire rod acts as the raw material for fabricating the inner and outer strands of a wire rope assembly. These strands are created by intertwining multiple individual wires, resulting in a robust and long-lasting rope. Typically, the wire rod utilized in this process consists of high-quality carbon steel, which imparts the necessary strength and resilience required for construction applications. The manufacturing process commences with the cleaning and lubrication of the steel wire rod to decrease friction during the twisting procedure. Subsequently, the wire rod is drawn through a sequence of dies to decrease its diameter and increase its length. This drawing process aids in aligning the steel's grain structure, thereby improving its strength and flexibility. Once the wire rod has been drawn, it is inserted into a stranding machine where numerous wires are twisted together to form individual strands. These strands are then combined in a specific pattern to construct the wire rope assembly, with the inner strands providing strength and the outer strands offering protection. The wire rope assembly is subsequently subjected to various quality control measures to ensure compliance with the required specifications for construction purposes. These measures may encompass testing for strength, flexibility, and resistance to corrosion. Upon approval, the wire rope assembly is deemed fit for use in construction projects. In the construction industry, wire rope assemblies crafted from steel wire rod find wide-ranging applications. They are frequently utilized in cranes and hoists for lifting heavy loads, offering a secure and dependable lifting solution. Wire rope assemblies are also employed in the construction of suspension bridges, where they provide support and stability. Furthermore, these assemblies are employed for securing structures, such as in the installation of safety barriers or anchoring systems. Overall, steel wire rod plays a pivotal role in the production of wire rope assemblies for construction purposes. Its strength, durability, and versatility make it an ideal material for diverse construction applications, ensuring the safety and dependability of structures and equipment.

- Q: How are steel wire rods used in the manufacturing of wire baskets for storage and organization?

- Wire baskets for storage and organization rely heavily on steel wire rods. These rods are essential for creating the wire mesh that shapes the basket. To begin with, the steel wire rods undergo a series of processes, including cleaning, straightening, and cutting. These steps ensure the rods are the desired length and free from any impurities. Once prepared, the rods are then passed through a wire-drawing machine. This machine reduces their diameter to the desired size and increases their tensile strength. Afterward, the wire rods are introduced into a wire mesh machine, where they are woven together to create a strong mesh pattern. The size of the mesh can be customized to fit the specific requirements of the wire basket. The resulting mesh is then cut into sheets of the appropriate dimensions. These sheets of wire mesh are shaped and welded together to form the structure of the basket. The steel wire rods provide not only strength and stability but also ensure the basket can withstand the weight of stored items without bending or deforming. Furthermore, the wire rods can be coated or treated with finishes like galvanization or powder coating. This enhances their durability and resistance to corrosion. As a result, the wire baskets can be used in various environments, even damp or corrosive conditions, without losing their functionality or degrading over time. In conclusion, steel wire rods are indispensable in the manufacturing of wire baskets for storage and organization. They serve as the primary material for creating the wire mesh structure. The strength, durability, and customization options offered by steel wire rods make them a crucial component in producing functional and long-lasting wire baskets.

Send your message to us

Carbon Steel Hot Rolled Wire Rod SAE1008

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords