High Quality Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering High Quality Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Quality Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Wire Rod SAE1008B:

Steel Grade: SAE1008B Standard: ASTM, GB

Diameter: 5.5mm, 6.5mm, 7mm,8mm,9mm,10mm,12mm,14mm

Type: Drawn Wire Alloy or Not: Alloy Brand Name: N-RIVER

Technique: Hot Rolled Place of Origin: China Mainland

Chemical Composition:

Please kindly find our chemistry of our material based on SAE1008B as below for your information

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Usage and Applications of Wire Rod SAE1008B:

After hot-rolled the products shaped into coil and delivery as finished product, including round, square, rectangular, hexagonal and so on. Since most of the products are round, it is generally called wire rod. Carbon steel wire rod is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

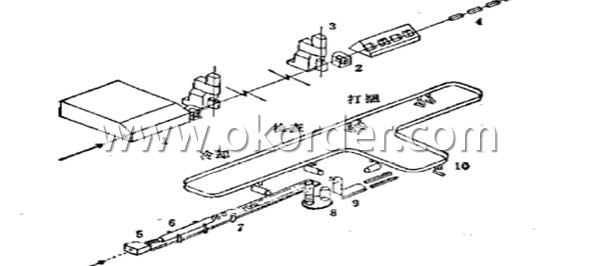

Production Process of Wire Rod SAE1008B:

1-Furnace 2-Roughing Mill 3-High-speed Finishing Mill 4-Water-cooled Device 5-Coiling Device

6-Cooling Device 7-Chain Conveyer 8-Spool Collecting Device 9-Spool Down Device 10-Hook Conveyer

Packaging & Delivery of Wire Rod SAE1008B:

Packaging Detail: products are packed in coil and then shipped by container or bulk vessel

Each coil weight: 2-3MT

Delivery Detail: within 45 days after received deposit or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: CFR, CIF

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard carbon steel wire rod we can supply:

Grade: H08A, 30MnSi, 62B-82B

Standard: AISI, BS, JIS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply carbon steel wire rod; if you need anything about building materials, please contact us.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: What are the different mechanical properties of steel wire rod?

- The different mechanical properties of steel wire rod include tensile strength, yield strength, elongation, hardness, and toughness.

- Q: What are the common industry guidelines for steel wire rod suppliers?

- The common industry guidelines for steel wire rod suppliers typically include ensuring consistent product quality, meeting international standards and specifications such as ASTM or ISO, adhering to safety and environmental regulations, providing timely delivery and reliable customer service, and maintaining competitive pricing.

- Q: How is steel wire rod classified based on its strength?

- Steel wire rod is classified based on its strength through a grading system known as the grade or grade number. The grade number indicates the tensile strength of the steel wire rod, which is the maximum amount of stress the wire rod can withstand before breaking. The higher the grade number, the stronger the wire rod is. The classification of steel wire rod based on its strength typically ranges from grade 1000 to grade 4000. Grade 1000 wire rod has the lowest tensile strength, usually around 1000 megapascals (MPa), while grade 4000 wire rod has the highest tensile strength, typically around 4000 MPa. Each grade of wire rod is designed for specific applications and industries. Lower grade wire rods are suitable for less demanding applications such as general construction, fencing, and mesh manufacturing. They are often used where high strength is not a primary requirement. On the other hand, higher grade wire rods are used in industries where exceptional strength is crucial, such as automotive, aerospace, and manufacturing of high-tensile steel cables. These wire rods are engineered to withstand extreme forces and are typically used in critical applications that require superior strength and performance. In addition to the tensile strength, steel wire rod can also be classified based on other properties such as ductility, corrosion resistance, and formability. These properties play a significant role in determining the suitability of the wire rod for specific applications. Overall, the classification of steel wire rod based on its strength is essential in selecting the right material for various applications. It allows engineers and manufacturers to choose wire rods that can withstand the required forces and perform optimally in their respective industries.

- Q: How is the steel wire rod market impacted by technological advancements?

- Technological advancements have significantly impacted the steel wire rod market by revolutionizing the manufacturing process, improving product quality, and enhancing operational efficiency. Advanced manufacturing techniques such as automation, robotics, and data analytics have streamlined production, leading to higher productivity and reduced costs. Furthermore, technological advancements in metallurgy and material science have resulted in the development of stronger and more durable wire rods, meeting the evolving demands of various industries. Additionally, innovations in wire rod coatings and surface treatments have expanded the range of applications and improved corrosion resistance. Overall, technological advancements have played a crucial role in shaping the steel wire rod market, driving growth, and enabling manufacturers to stay competitive in a rapidly changing industrial landscape.

- Q: What are the different types of steel wire rod finishes for improved paint adhesion?

- There are several types of steel wire rod finishes that can be used to enhance paint adhesion. Some common options include galvanized finishes, which involve coating the wire rod with a layer of zinc to provide corrosion resistance and improve paint adhesion. Another option is phosphatized finishes, where the wire rod is treated with a phosphate coating to promote adhesion between the steel and paint. Additionally, manufacturers may opt for a chromate finish, which involves applying a chromate conversion coating to the wire rod to enhance paint adhesion and provide corrosion resistance. These finishes are widely used in various industries to ensure a strong and durable bond between paint and steel wire rods.

- Q: What are the different mechanical tests conducted on steel wire rod?

- Some of the different mechanical tests conducted on steel wire rod include tensile strength testing, hardness testing, impact testing, and bend testing. These tests help determine the strength, durability, and flexibility of the steel wire rod, ensuring it meets the required specifications and standards for various applications.

- Q: What are the different types of steel wire rod surface cleaning methods for wire drawing?

- There are several types of steel wire rod surface cleaning methods for wire drawing. These include mechanical cleaning, chemical cleaning, and electrolytic cleaning. Mechanical cleaning involves the use of brushes, abrasive pads, or shot blasting to remove dirt, rust, and scale from the surface of the wire rod. Chemical cleaning involves the use of acids or alkaline solutions to remove contaminants and oxide layers from the surface. Electrolytic cleaning uses an electric current to dissolve and remove impurities from the wire rod surface. Each method has its advantages and suitability depending on the specific requirements of the wire drawing process.

- Q: What are the different high-temperature properties of steel wire rod?

- Steel wire rods have several high-temperature properties that make them suitable for various applications. One of the key properties is high thermal stability, which allows the wire rods to maintain their structural integrity even at elevated temperatures. This is crucial in industries such as automotive and aerospace, where steel wire rods are used in parts that are subjected to high temperatures during operation. Another important property of steel wire rods at high temperatures is their resistance to oxidation. Steel wire rods are typically coated with a protective layer, such as zinc or galvanized coating, which acts as a barrier against oxidation. This prevents the wire rods from corroding and losing their strength when exposed to high temperatures and harsh environments. Furthermore, steel wire rods exhibit excellent mechanical properties at elevated temperatures. They have high tensile strength and good creep resistance, which means they can withstand heavy loads and prolonged exposure to high temperatures without deforming or breaking. This makes them ideal for applications where strength and durability are required, such as in construction and manufacturing industries. Moreover, steel wire rods also have good thermal conductivity, allowing them to efficiently transfer heat. This property is beneficial in applications such as heating elements, where the wire rods are used to generate and distribute heat evenly. In summary, the different high-temperature properties of steel wire rods include thermal stability, resistance to oxidation, excellent mechanical properties, and good thermal conductivity. These properties make steel wire rods a versatile and reliable material for various high-temperature applications in different industries.

- Q: How is steel wire rod used in the manufacturing of wire forms for automotive seating?

- Steel wire rod is used in the manufacturing of wire forms for automotive seating as it provides the necessary strength and durability required for these components. The wire rod is first processed and shaped into various forms such as springs, clips, and frames, which are then incorporated into the seat structure. These wire forms play a crucial role in providing support, flexibility, and stability to the automotive seats, ensuring comfort and safety for the occupants.

- Q: What are the common types of steel used for wire rod production?

- Wire rod production utilizes a variety of steel types, including carbon steel, alloy steel, and stainless steel. Carbon steel stands as the most prevalent option, owing to its affordability and versatility. Comprised mainly of iron and carbon, it also contains trace amounts of other elements. In contrast, alloy steel merges iron with additional elements like manganese, chromium, or nickel. This type of steel boasts heightened strength, durability, and resistance to wear and tear. Conversely, stainless steel finds common use in wire rod production, particularly when corrosion resistance is imperative. With a high chromium content, it forms a protective oxide layer on the surface, preventing rust and corrosion. These diverse steel types present varying properties and characteristics, enabling manufacturers to meet specific requirements for wire rod production across different industries.

Send your message to us

High Quality Hot Rolled Wire Rod SAE1008 SAE1006 SAE1018

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords