calcium silicate board --- Insulated Interior Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

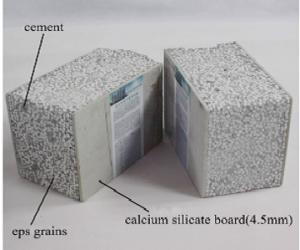

Composition: EPS+cement+calcium silicate board

Q3: How do we guarantee the quality?

A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20-40 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Package (20GP)

Specification (mm) | Quantity (pcs) | Area (sqm) | Weight (kg) |

2270*610*60 | 306 | 424 | 19500 |

2270*610*75 | 252 | 349 | 18200 |

2270*610*90 | 207 | 287 | 17300 |

2270*610*100 | 189 | 262 | 17300 |

2270*610*120 | 153 | 212 | 15000 |

2270*610*150 | 126 | 175 | 13200 |

Usage

JY wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of

washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

Project

Certificate

Q1: How soon can we receive the goods after purchase? A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q2: How to make a quick resolution for after service? A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Polyurethane color steel sandwich panels can not be used

- Can be used, but the splicing will be hot and cold bridge phenomenon, the loss of temperature. The best way is to use the local polyurethane sprayer spray foam, so no seams, the best insulation effect.

- Q: Activities of the sandwich board, the middle of the middle of the kind of foam, a square meter how much money? And how much is that one window? Is it aluminum? How much is the door? Fujian Nanping where cheaper, I was Shaowu's.

- A square meter about 180 yuan. Window 1.15 / 1.8 meters difference of less than 100 yuan is steel, but there is a good that the door has a color of 80/200 centimeters of 90 yuan. The door will be more than a hundred points.

- Q: Decorative material sandwich board expensive or joinery board expensive?

- Sandwich panels are wood chips inside. Blockboard is a small piece of wood inside, of course, is the joinery board expensive.

- Q: Flammable and toxic "" "", how long life?

- There are two types of polyurethane foam and polystyrene foam!

- Q: Purification workshop manual sandwich board how much money to install a square can do

- You search under the Suzhou Jinjiaba town and Zhenze town side of the factory, cheaper.

- Q: Bubble (EPS) color steel sandwich panels how to wear thread

- That depends on the savvy! Way more than difficult!

- Q: Color plate and color steel sandwich panel difference

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: Sandwich board machine how much money

- Metal insulation sandwich board production line, probably in the 23-30 million range, the current OKorder Changxing, Baosheng, Po day, good quality, finished product width 970,980,950 type,

- Q: EPS material sandwich board is fire

- Can not fire, EPS if the addition of flame retardant can be achieved from the fire self-extinguishing, but there are open fire or burning.

- Q: Is there any profit in the rock wool sandwich panels?

- f course, ah, foam sandwich panels are not allowed to use the fire department, optimistic about the Yanmian sandwich panels, glass wool sandwich panel market prospects, Shandong Zibo permanent company is the largest sales of Yanmian sandwich panels manufacturers, Steel sandwich panels, save money is the last word!

Send your message to us

calcium silicate board --- Insulated Interior Wall Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords