calcium silicate board --- Interior Wall Paneling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

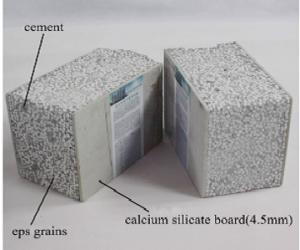

Composition: EPS+cement+calcium silicate board

Q3: How do we guarantee the quality?

A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20-40 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Package (20GP)

Specification (mm) | Quantity (pcs) | Area (sqm) | Weight (kg) |

2270*610*60 | 306 | 424 | 19500 |

2270*610*75 | 252 | 349 | 18200 |

2270*610*90 | 207 | 287 | 17300 |

2270*610*100 | 189 | 262 | 17300 |

2270*610*120 | 153 | 212 | 15000 |

2270*610*150 | 126 | 175 | 13200 |

Usage

Our wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of

washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

Project

Certificate

Q1: How soon can we receive the goods after purchase? A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q2: How to make a quick resolution for after service? A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: OKorder Wang Teng color steel production and sales of a variety of color steel plate, Caigang tiles, Caigang rock wool sandwich panels, Caigang polyurethane sandwich panels, Caigang foam sandwich panels, Caigang extruded sandwich panels, color Steel paper honeycomb sandwich panels, galvanized sheet, floor board, Caigang sandwich panels, C steel, color steel activities, and other products.

- OKorder Wang Teng Choi Steel Structure Co., Ltd. specializing in the production of sandwich panels foam sandwich panels Yanmian sandwich panels polyurethane sandwich panels glass wool cotton sandwich panels paper honeycomb sandwich panels aluminum honeycomb sandwich panels phenolic sandwich panels hand sandwich panels stainless steel Sandwich panel sandwich panel offer sandwich panel specifications sandwich board type sandwich panel manufacturer sandwich panel density sandwich panel thickness sandwich panel wholesale sandwich panel sales sandwich panel suppliers - OKorder Wang Teng color steel structure limited the company

- Q: How to install the cold sandwich sandwich sandwich panels

- If the use of polyurethane cold storage board, then use the structure of the installation of the installation time can be reported to us can also install their own This is a drawing in accordance with the drawings can be installed

- Q: Color plate and color steel sandwich panel difference?

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: The foam sandwich panels of the insulated chicken coop are burned! How to do hollowing out?

- Magnesium cement curing to release a high heat, generally in the 1000 ~ 1350J / gMgO, and the heat release rate is very fast, the highest reaction system center temperature up to 150 degrees Celsius. Ordinary Portland cement hydration heat is only 300 ~ 400J / g, can be seen magnesite cement is the ordinary cement hydration heat 3 to 4 times. As can be seen from the above data, especially in the summer high temperature production, must strictly control the magnesite cement curing process. At present in Hebei Wen'an, Cangzhou area, in order to save production space, usually finished a board, and then according to this board for the operating platform in the above do 3 to 5, we all know, thermal conductivity of foam material is poor, and Ling Magnesium cement curing is a fast high heat process, so the production often encountered due to exotherm is too high and burned foam board situation, that is, "burn board" "hollowing" phenomenon.

- Q: Sandwich board moldy how to deal with

- If the mold is generally difficult to clean out, you can use some alcohol class wipe, the mold to erase, it is best to go online to buy a small amount of Ai Hao Seoul fungicide spray up to ensure that the sandwich board is not Re-moldy.

- Q: Is there a requirement for the density of the steel wall

- Why choose foam sandwich panels? Know the European rock wool color plate it? European rock wool color steel plate is the steel structure of the system of energy-saving composite materials, with two high-quality color coated steel plate after forming as a panel, the use of high-quality rock wool fiber turned 90 ° after the core material Fiber and steel plate into a vertical shape), through the high strength, high viscosity of the two-component adhesive, high-quality basalt cotton and color steel plate bonding, the double-track heating and heating from the new high-end building materials The

- Q: 2x8 foor joists above not supporting the roof

- Nope! You'll have to use a double 1 3/4 x 14 LVL. The best you can do with a double 2 x 12 is between 6' 3 and 8' 1 depending on the width of the building parallel to the joists.

- Q: What is the difference between the sandwich panel and the composite board?

- Metal sandwich panels are made of two-layer metal panels (or other material panels) for the surface material, insulation materials to do the core material, with adhesive composite or direct foam curing molding compound. Building insulation sheet industry in the insulation board refers to the sandwich panels, composite board is popular called. Metal composite panel in the industry refers to a layer of metal plate covered with another metal plate, in order to reduce the use of the effect (corrosion resistance, mechanical strength, etc.) under the premise of saving resources and reduce the cost of the effect.

- Q: Can the rock wool sandwich panel be used as a ceiling?

- Rock wool sandwich panels can be made ceiling, but the rock wool sandwich panels should be processed again.

Send your message to us

calcium silicate board --- Interior Wall Paneling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords