Raw Materials for Refractory Calcination Rotary Kiln for Bauxite Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Production Capacity: | Refer to specification | Place of Origin: | Henan, China (Mainland) |

| Brand Name: | cnbm | Model Number: | Refer to specification | Voltage: | 220 |

| Power(W): | Refer to specification | Dimension(L*W*H): | according to models | Weight: | various |

| Certification: | CE,ISO9001 | Warranty: | one year | After-sales Service Provided: | Engineers available to service machinery overseas |

| Calcination rotary kiln for bauxite: | high efficiency | Factory: | 50,000 square meters closed workshops | Technology: | 30 years experienced technology support |

| Technical service: | the whole using life | Product supply: | crushing machine, grinding machine, ore dressing equipment | Grinding machine: | Raymond mill, ball mill, coal mill |

| rotation speed: | 0.10-3r/min | capacity: | 0.9-42t/h | Workers: | more than 660 |

| Experts: | more than 80 with senior engineering technicians |

Packaging & Delivery

| Packaging Details: | standard containers, bare main machine, motors and small parts are packed in wooden cases. |

| Delivery Detail: | 5~25 working days after placing the order |

Specifications

Calcination rotary kiln for bauxite

1.Good sealability

2.Precise control,energy saving

3.CE,ISO

4.30 year experience

Product Description

Features of calcination rotary kiln for bauxite

1) It is an inclined rotary cylinder, the raw material enter the cylinder through the high end of the machine,then move in with the movement of of the rotary kiln. Therefore, the rotary kiln is a conveying equipment.

2) It is a combustion device.

3) It has the function of heat exchange.

4) It has the chemical reaction function.

5) It has the function of degrading and re-using the waste.

Advantages of calcination rotary kiln for bauxite

◊. Energy-saving and environmental-protection, using wastes as fuel

◊. Solid structure, stable operation

◊. High-usage of thermal energy

Application of calcination rotary kiln for bauxite

1. Rotary kiln is commonly used in the production process of catalytic agent, molecular sieve and zinc oxide, etc.

As a result, you can find rotary kiln for bauxite in variety of industries, like steel annealing and nonferrous smelting industries, metallurgy and chemistry fields, and building industries, and more.

2. Rotary kiln system, which is also called a rotary calcine kiln, is a commonly used building material machine. Classifying by material properties, a rotary kiln falls into cement kilns, metallurgy chemical kilns, and lime kilns.

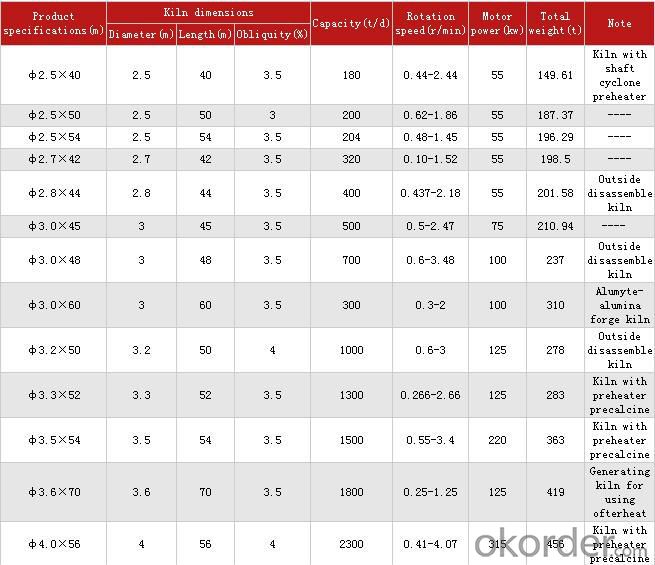

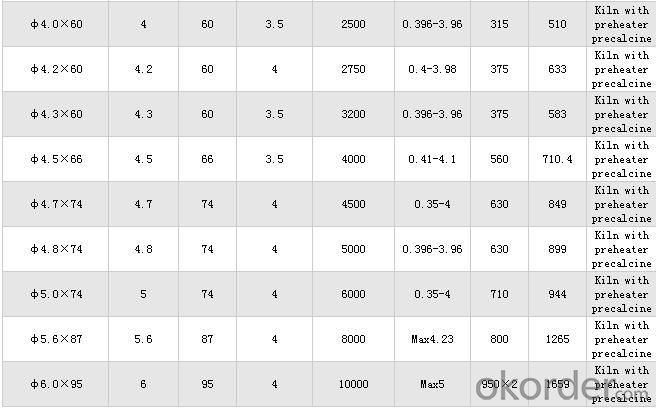

Technical parameters of calcination rotary kiln for bauxite

- Q: Preparation of refractory clay

- Is it to make refractories? Add some andalusite to the refractory mortar will improve the effect.

- Q: What are the materials of insulation firebricks?

- The raw materials of firebricks, firebricks have various raw materials, and the composition of which can be divided into six categories: soil, stone, sand, mineral, powder and others. One of the raw materials, soil: bauxite, kaoline, clay, diatomite Another raw material, stone: fluorite, kyanite, andalusite, forsterite, vermiculite, mullite, pyrophyllite, chlorite, dolomite, sillimanite, magnesia-alumina spinel, and silica Another raw material, sand: clay sand, zircon sand, quartz sand, and magnesite Another raw materials, mineral: chromium mineral Another raw material, powder: aluminum powder, micro-silica powder, and silicon powder Another raw materials, others: asphalt, graphite, phenolic resin, perlite, cenosphere, sialon, corundum, silicon sulfate, silicon carbide, sodium silicate, silica sol, boron carbide, calcium aluminate cement, nitride material, haydite, aluminum oxide, alumina sol and zirconia, etc.

- Q: Can quantitative feeder be used in refractory plant? Thank you

- Well, can the Weifang Sanyou automation equipment production chain plate feeder is fully applicable to the measurement and control of boring high temperature, chain plate feeder with 16 4-5MM manganese plate.

- Q: How is the division of the fire resistant level of the rock wool board?

- The fire rating of European style rock wool board is level A , which uses Da Guang Beijing Jinyu rock wool board, with the main advantages are: 1, High acidity coefficient: The high coefficient of acidity greatly improves the life resistance and weather resistance of the rock wool board. 2, Hydrophobic air permeability: According to the picture, Jinyu Star rock wool is water-repellent, at the same time it also has breathability, so the liquid water is not easy to dip into the rock wool, and the water vapor and other gas molecules could pass through the rock wool. In particular, the insulation materials have this feature which enables the building to have "respiratory function" thus making the room more comfortable and preventing anti-mildew phenomenon happening indoor. 3, Environmental protection: The goldfish can survive freely, which just shows it is environmental; 4, High strength: The advanced pleating and curing technology make the rock wool board tensile and high compressive strength. It not only can be applied on the external wall thermal insulation and sandwich board core material, but also can be used to make structural cotton in the flexible waterproof roofing. Its quality is so stable that it is convenient in construction and durable in use. 5, Fireproofing: Not just talking about the fire rating, but the fireproofing time, which is generally up to two hours, and can be used for lining thermal insulation fire-resistant part of the glass curtain wall, through-wall pipe seal, pier?between?two?windows, window sill wall and other parts; 6, Derived advantages: Agriculture applies the soilless cultivation cotton;

- Q: what's the varieties of fire-proof?sealing?material?

- Fire blocking material currently on the market include: fire stopping board, foam blocking material, flame resisting module, fire-resisting sealant, flexible organic caulking, WXY-II and fire retardant bag, etc. fire-proof?sealing?material is widely used in building construction and can ensure high-temperature flame and smoke from fires not spread to another fire?compartment, different buildings generally use different sealing methods. Pipeline is generaly sealed by pouring concrete board or mortar.

- Q: whether the fire resistant level of aerated concrete building blocks can reach the grade one?

- the fire resistant level of aerated concrete building blocks can reach the grade one level. Aerated concrete strength grade shall be divided according to the concrete cubic compressive strength value. Use the symbol C and the cube compressive strength value (in N / mm2 or MPa gauge) to express. According to GB50010-2002 "concrete structure design specifications" provisions, ordinary concrete is divided into fourteen levels, namely: C15, C20, C25, C30, C35, C40, C45, C50, C55, C60, C65, C70, C75, C80 .

- Q: How much is the duration of fire resistance of the porous brick shale?

- This is really a simple question. The temperature should be limited within 1050℃, or it will be scorched. I think 980℃would be acceptable.

- Q: How to determine the fire resistance rating of the aluminium-plastic?panel?

- Class A incombustible and thermal insulation material: inorganic active wall thermal insulation material, cement foam insulation board, glass bead thermal mortar, rock wool board, glass wool board, foam ceramics, etc. With many characteristics of low density, low thermal conductivity, high pressure bearing capacity, convenience of construction, economy and durability, A class incombustible material is widely used as thermal insulation material for heat pipelines, thermal equipment, other industrial pipe-line equipment and industrial buildings, and thermal insualtion and sound absorption material for the building envelop of industrial and civil buildings. Because of good thermal stability, it is more often used as fire-proof and protective coating material of the steel structure.

- Q: What are the features of construction class A fire resistant door ?

- 1, fireproof and thermal insulation Foam cement board is a Class A non-combustible inorganic heat preservation material which has good fireproof?performance can remain integrity after 3 hours baking at 1200℃. It can be used in buildings to improve fireproof?performance.

- Q: What is refractory aggregate?

- It includes two categories: coarse aggregate and fine aggregate.

Send your message to us

Raw Materials for Refractory Calcination Rotary Kiln for Bauxite Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords