Butterfly Valve Made in China on Hot Sale with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

2.Main Features of the Manual Wafer Butterfly Valve

a)Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

b)Soft seat. Replaceable. Increase of service life.

c)Double half shaft without pin.

d) Square and short neck. Easy to stick scutcheon and cost saving.

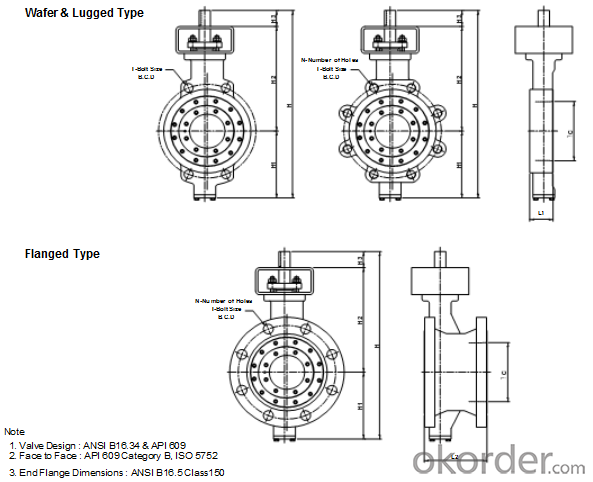

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: Proportional valve why than other small pipeline valves

- 3.8 valveGraphical representation of numbers, names, symbols3.8.1 angle valve at room temperature3.8.2 cold angle valve for low temperature use3.8.3 stop valve at room temperature3.8.4 ball valve often 9 temperature3.8.5 valve at room temperature3.8.6 butterfly valve at room temperature3.8.7 check valve flow from blank triangle to non empty triangle3.8.8 pressure reducing valve, small triangle for high voltage end3.8.9 throttling valve is needle valve3.8.10 three-way valve for normal temperature use3.8.11 four way valve used at normal temperature3.8.12 safety valve spring type safety valve3.8.13 trap actual drawing, you do not have to draw arrows3.8.14 inflator, cold box, little gas huff and puff, safe useValve for normal temperature of regeneration valve of 3.8.15 reverse stop valve3.8.16 reverse loading cold angle valve

- Q: Z11H/Y forged steel gate valves H/Y what does that mean?SZ45H S what do you mean?Blow 2Z41YGY-40P, what do you think?What does NKZ61H vacuum valve NK mean?What does DS/Z64H water seal valve DS mean?Specific valve number how to see ah, detailed information, thank you!

- The meaning of valve number:Valve type Z, J, L, Q, D, G, X, H, A, Y and S respectively: gate valve, globe valve, throttle valve, ball valve, butterfly valve, diaphragm valve, plug valve, check valve, safety valve, relief valve, drain valve.The connecting codes for valves are 1, 2, 4, 6, 7, respectively: internal thread, 2, outer thread, 4, flange, 6, welding, 7, pair.Valve transmission mode code 9, 6, 3, respectively, said: 9, electric, 6, pneumatic, 3, turbo worm.Body material Z, K, code Q, T, C, P, R and V respectively: grey cast iron, malleable cast iron, ductile iron, copper and alloy, carbon steel, stainless steel, chrome nickel chromium nickel molybdenum stainless steel, chromium molybdenum vanadium steel.Seat sealing or lining R, T, X code, S, N, F, H, Y, J, M, W respectively: austenitic stainless steel, copper alloy, plastic, rubber, nylon plastics, fluorine plastic, Cr stainless steel, hard alloy, rubber lining, Monel alloy, valve body material.

- Q: What does LBC mean in a valve?

- LB and 800 are together. 800LB means 800 pounds of stress, and P should be PRESSURE.Valve (Famen) is a control component in the fluid delivery system. It has the functions of closing, adjusting, guiding, preventing reverse flow, stabilizing voltage, shunting or overflow and releasing pressure.Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow.

- Q: What does the "XV" valve mean?

- XV:X said V is plug valve, said valve body material is chrome molybdenum vanadium steel.

- Q: What is a lift rod valve?

- Lever valve stem nut in the valve plate, it with the disc (hand wheel) to open the turn, its stem pull the valve head and higher than the valve disk, also known as the bar valve. It is different from the dark rod valve, dark rod valve stem nut in the valve body, when the disc rotates, the stem will not rise.

- Q: How to identify the good or bad of the valve, without pressure test and instrument?

- First, the appearance, two according to the standard to see flange thickness, outer circle, wall thickness and other dimensions are standard, 3 see details.

- Q: Ketem valve relative to other valve companies in the industry what are the advantages?

- The electric actuator built-in servo system, no need to add servo amplifier, input 4-20mA signal and 220V AC power supply can control the operation. Compared with the ordinary electric ball valve, the utility model has the advantages of compact structure, small size, light weight, close distance between the valve seat and the end face flange, less material retention, superior sealing performance, etc..

- Q: What should be checked before using the valve?

- 5, check valve disc or spool movement is flexible and accurate, no bias, displacement or skew phenomenon6, spring-loaded safety valve should be sealed, positioning lever type safety valve should have the weight of the device7, rubber lining, lining enamel and plastic lined valve body surface should be smooth, the lining layer and the substrate firmly, no crack, blister defects, using high frequency electric spark generator to inspect the lining surface, not found in liner breakdown (white flash phenomenon) is qualified8, the valve flange sealing surface should meet the requirements, and shall not have radial scratches

- Q: Representation of several types of valves

- Valve body material:Z grey castings (usually not shown)X malleable ironQ nodular cast ironT copper alloyB lead alloyII chromium molybdenum alloy steelL chrome alloyP chromium nickel steelV (II) chromium molybdenum vanadium alloy steelR cr.ni.mo.ti steelF fluoroplasticP leather (Shen Penggang)S plasticD nitrided steelCJ lining adhesiveTC magnetic boringCS lined plasticCQ lined with leadW sealing ring is machined from valve body, C carbon steel (generally not shown)G ferrosilicon

- Q: Is there any difference between the valve and the water valve?

- There is no difference between the low pressure lubricating oil pump, as long as the excuse right on the line, not to pressure, design pressure ball valve common does not exceed 3MP, the maximum pressure of only small gear pump vane pump is 2.5MP, the other piston pump, gear pump, the pressure is above 6.3MP. Certainly not. Unless using high pressure water pipe valve.

Send your message to us

Butterfly Valve Made in China on Hot Sale with Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches