Building Hoist SC200 Relay Schneider Brand

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

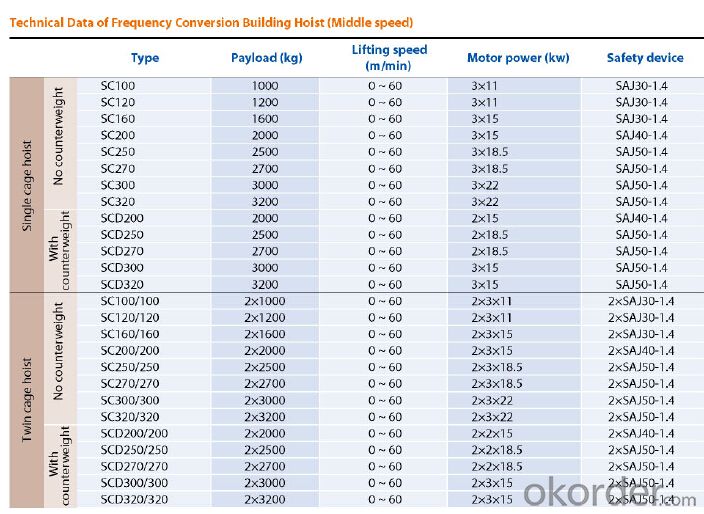

Payload(kg):2000

Lifting Speed(m/min):0~60

Motor Power(kw): 3*15

Safety Device: SAJ40-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC200

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Features of Building Hoist

●Due to the strict raw material procurement control system, our drive motors for construction hoist/ building lift /material elevator for bridge/ tower / chimney / building is guaranteed with safe and reliable performance.

●The steel, electrical components, hoist cables, high strength bolts and spare parts are all introduced from well-known international and domestic suppliers.

●Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

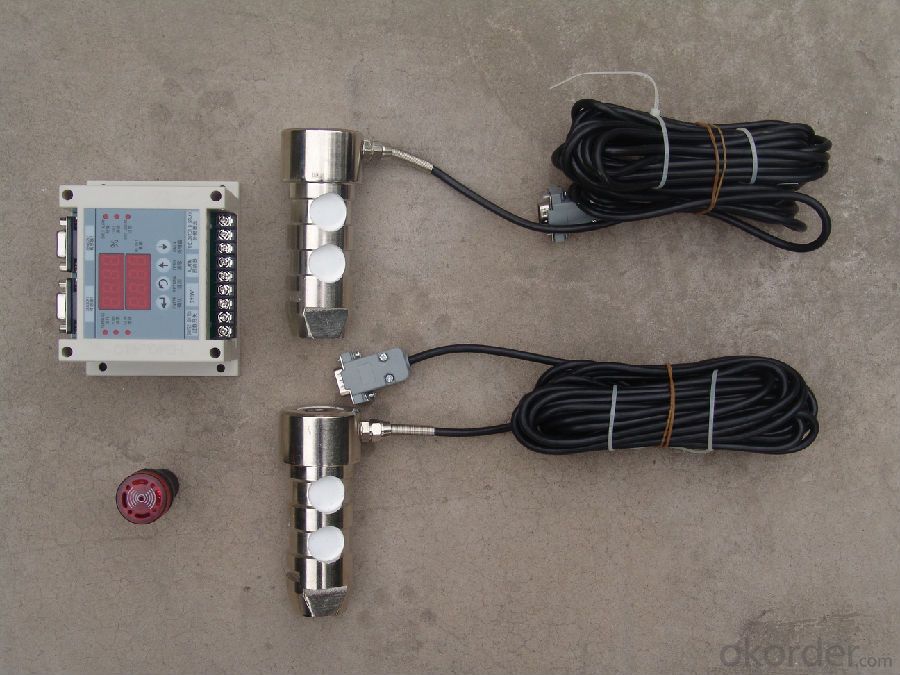

Building Hoist Images

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is it possible to utilize a building hoist for elevating construction materials?

- <p>Yes, building hoists are commonly used in construction to lift materials. They are designed to transport heavy materials, such as bricks, cement, and steel, vertically between floors. These hoists are crucial for efficient construction, especially in high-rise buildings, as they reduce manual labor and increase safety by minimizing the need for workers to carry heavy loads up ladders or stairs.</p>

- Q: This question asks for the methods used to maintain and care for a building hoist, which is a type of lifting equipment used in construction.

- <p>Regular maintenance of a building hoist is crucial for safety and efficiency. Key methods include daily inspections of cables, hooks, and safety devices for any signs of wear or damage. Lubricate moving parts as per the manufacturer's guidelines to reduce friction and prevent rust. Ensure that all electrical components are clean and dry, and check for any loose connections or damaged wires. Perform load tests periodically to confirm the hoist's lifting capacity and safety. Keep the control panel and all operational areas clean and free from debris. Regularly check the hoist's anchorage to ensure it is secure. Adhere to all manufacturer's recommendations for maintenance intervals and procedures. Proper maintenance can extend the life of the hoist and prevent accidents.</p>

- Q: This question asks for the cost associated with purchasing and installing a building hoist.

- <p>The cost of buying and installing a building hoist can vary significantly depending on several factors. The type and capacity of the hoist, the height of the building, and the complexity of the installation are key determinants. On average, the cost can range from $10,000 to $50,000 for the hoist itself, with installation costs potentially adding another 20-50% to the total. However, for very tall buildings or specialized hoists, the price can exceed $100,000. It's crucial to obtain quotes from multiple suppliers and installers to get an accurate estimate for your specific project.</p>

- Q: This question asks about the typical issues encountered when constructing a building hoist and the methods to address these problems.

- <p>Common problems in building hoists include mechanical failure, safety hazards, and improper installation. Solutions involve regular maintenance to prevent mechanical issues, strict adherence to safety protocols to mitigate hazards, and professional installation to ensure the hoist is correctly set up. Additionally, using modern technology for monitoring and control can help to identify and rectify problems early. Ensuring proper training for operators is also crucial for the safe and efficient operation of building hoists.</p>

- Q: This question asks about the various types of control systems used in building hoists, which are essential for the safe and efficient operation of construction elevators.

- <p>There are several types of building hoist control systems that ensure the safe and efficient operation of construction elevators. These include: 1. Manual Control Systems: Operated by a human operator who controls the hoist's movement. 2. Semi-Automatic Control Systems: Combine manual operation with some automated features, like automatic level selection. 3. Fully Automatic Control Systems: Completely automated, with the hoist moving between floors without manual intervention. 4. Microprocessor-Based Control Systems: Utilize advanced microprocessors for precise control and monitoring. 5. PLC-Based Control Systems: Use Programmable Logic Controllers for robust and customizable control. 6. Wireless Control Systems: Enable remote operation and monitoring of the hoist. Each system has its advantages and is chosen based on specific project requirements, safety standards, and budget considerations.</p>

- Q: This question asks for safety precautions that should be taken when using a building hoist, which is a type of lifting equipment used in construction.

- <p>Safety measures for using a building hoist include regular inspections and maintenance, ensuring all safety devices are in good working order, securing all loads properly, and not overloading the hoist. Operators must be trained and certified. Protective barriers should be in place to prevent unauthorized access. Emergency stop switches should be readily accessible. Workers should wear appropriate personal protective equipment, and communication between the hoist operator and those on the ground should be clear and effective. Adhering to these measures helps prevent accidents and ensures the safe operation of the building hoist.</p>

- Q: This question asks for a comparison between two types of building hoists: those that are electric and those that use electric motors. It seeks to understand the key distinctions between these two systems.

- <p>Electric building hoists are powered directly by electricity and typically use simpler electric motors for lifting and lowering loads. They are generally easier to install and operate, with direct control over the motor speed and direction. On the other hand, electric-motor building hoists are more complex, often incorporating advanced motor technologies and control systems. These hoists may offer features like variable speed control, energy efficiency, and smoother operation. The main differences lie in the sophistication of the motor and control systems, with electric-motor hoists often providing more precise control and better performance for heavy-duty applications.</p>

- Q: Is the construction elevator the same as the construction elevator

- Construction lifter and building construction elevator, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction lifter is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. There are many kinds of elevators in construction, there are no two kinds of weights and weights in the way of operation, and they are controlled by manual control and automatic control. You can also add inverter and PLC control modules as needed, and also add floor calling devices to the peace layer. The structure principle and characteristics of construction lifter: construction lifter for meet the needs of the lean construction bridge, chimney, etc, it according to the building shape, install the guide frame tilt, and hanging basket level, along the inclined guide plane running up and down.

- Q: Is it possible to utilize alternative lifting equipment in place of a building hoist for specific tasks?

- <p>Yes, for certain tasks, alternative lifting equipment can be used instead of a building hoist. Cranes, forklifts, and telescopic handlers are common substitutes. The choice depends on the task's specific requirements, such as the weight of the load, the height to which it needs to be lifted, and the available space. Each piece of equipment has its own advantages and limitations, so it's crucial to select the appropriate one based on the project's needs to ensure safety and efficiency.</p>

- Q: The tower crane is on a surface with the construction elevator, and only 2 or 3 meters away. Is that allowed

- Congratulations, it's a tragedy when you want to start the tower

Send your message to us

Building Hoist SC200 Relay Schneider Brand

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords