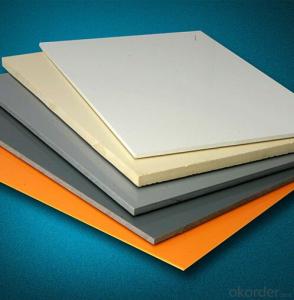

PVC Colored Rigid Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Rigid Sheet is a kind of high-tech and environment-friendly product, produced by advanced equipment imported from Austria. It is extruded and shaped by PVC powder, which is the main ingredient, and mixed with other additives, such as stabilizer. PVC Rigid sheet has many advantages, such as strong, hard, shinny or matt surface, UV resistance, anti-corrosion, etc.. It is perfect substitute of stainless steel and other anti-corrodibility composite materials. It is widely used in many fields: chemical industry, oil industry, galvanization, environment-protecting equipment, mining industry, medical appliance, advertising, construction and so on.

Products Details

| Description | PVC Rigid Board/sheet/Panel; PVC Board/sheet/Panel |

| Width(mm) | 910, 1000, 1220, 1300, 1500 etc. max. width is 1500mm |

| Length(mm) | 1830, 2000, 2440, 3000 etc. Upon your request |

| Thickness(mm) | 1-30mm |

| Density | 1.4~1.6g/cm3 --- grade A+ :1.4g/cm3; grade A: 1.5g/cm3; grade B: 1.6g/cm3 |

| Surface | Glossy, matt, textured available upon your design |

| Colors | white, light grey, dark grey, yellow available upon your request |

Application

Industry: chemical industry, galvanizing industry.

Advertising: display board, printable screen printing, digital printing, laminated.

Construction material: indoor decorating, wall paneling, composite door panel.

Electron: electric and communication equipments.

Specical Application

UV Stabilized Sheet in 3 years, 5 years, 10 years used for outside advertising and constructions, such as Signboard, wall claddings, air vents and so on.

Color Stabilized sheet in 1 year, 3 years, 5 years used for inside or outside where there are high request about color, such as lettering, display for long time and so on.

Tolerances

| RANGE (based on thickness) | THICKNESS(mm) | LENGTH(mm) | WIDTH(mm) | RECTANGULARITY | |||||||||||||||

| < 3mm | ±(0.08+0.03*d) | within ±10mm | within ±5mm | within +3mm/m | |||||||||||||||

- Q:Pvc how to heat the deformation of soft board, to make their own shape

- The material is called thermoreversible crosslinking agent, also known as sodium dicyclopentadiene dicarboxylate, in the PVC processing process by adding 0.5%, can make PVC sheet or pipe heated to 50-60 degrees can be free deformation, if you want to return to the original state, but also Can be heated to the original state. This material has memory.

- Q:Pp board and pvc board 20mm thick now how much money a square?

- Production of PVC external wall hanging plate with anti-aging, anti-radiation, anti-corrosion, fire-retardant, handsome in appearance, easy to install features for all types of buildings indoor and outdoor walls, shed decoration, is a new Green materials. The newly developed hot-dip galvanized electrostatic spray guardrail has the characteristics of simple installation, high strength, no pollution, corrosion resistance, maintenance-free, self-cleaning and so on. It is suitable for industrial and mining enterprises, institutions, municipalities, roads, parks, Schools and other places

- Q:What is the PVC board and KT board, what are the specific role?

- Is to do what is the painting is to use PVC board

- Q:How to weld PVC hard board

- Hot plate welding (for flat type parts), it is the use of electric heating metal mold to be connected to the surface of plastic parts of the thermoplastic welding process. Almost suitable for all large or small thermoplastic parts. Particularly suitable for welding less soft semi-crystalline thermoplastics. As the different mold surface temperature can be applied to two different thermoplastic materials, this process is best suited for welding different materials. Hot plate welding can achieve high welding strength. But the cycle of the process may be relatively long, small parts need 15s, and a lot of parts to be a few minutes.

- Q:PVC wood-plastic board Saw cut out of the board is not rectangular, sometimes parallelogram is sometimes how to adjust the trapezoid

- , the preferred work before, will push the table around the cleaning and cleaning table. 2, check whether the sharp blade, the size of the blade is in a line 3, the test machine: time about 1 minute to see whether the normal operation of the machine, check the size of the blade rotation direction, to ensure that the blade rotation direction is correct. 4, start work, will prepare the plate on the push bed, adjust the stall size. Then start working. 5, to maintain the PVC wood-plastic plate placed straight, no bending plate, 6, the plate should be close to the block, can not move; 7, according to the thickness and hardness of the plate to adjust the opening speed, the machine will be advancing uniform, not too fast too fast. 8, such as out of the board corner is defective, should consider replacing the saw blade. 9, open a small material, the application of wood to push forward.

- Q:What is the proportion of PVC board? Thank you!

- According to the different weight of the process will be different, such as the foam process will be the point of the extrusion process will focus on the floor, but as the words of the floor than other wood ah tile ah what is much lighter

- Q:Pvc floor and floor leather is the same?

- Pvc floor and floor leather is not the same material, is not the same. "PVC floor" refers to the use of PVC material produced by the floor. Specifically, polyvinyl chloride and its copolymer resin as the main raw material, adding filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet on the substrate, the coating process or by rolling, extrusion or extrusion Craft production. Floor leather (not PVC plastic flooring), is a kind of floor materials, plastic products, is a modern living room decoration indispensable one of the ground material, the thickness of 1.5 mm or more, wear-resistant layer 0.1 or more, plastic floor leather is soft floor.

- Q:Bathroom with pvc ceiling is good or aluminum plate good? why?

- Bathroom ceiling or choose an integrated ceiling class, With aluminum-plastic plate material ceiling, its practice and effect of course have their own advantages, Although we are aluminum composite panel manufacturers, but frankly speaking, the use of aluminum-plastic board is mainly moisture moisture problem. Not the aluminum-plastic plate material itself, but supporting the accessories and accessories, such as wood plywood, seam density and so on.

- Q:Pvc soft plate welding how to melt?

- Hot glue gun

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Colored Rigid Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords