Brown Gum Anti-Slip Tape with Solvent Based Acrylic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Anti-slip Tape with Solvent Based Acrylic

1. Structure of Anti-slip Tape Description

surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material;

base paper: white/leather silicone paper

middle layer: PET, PP, PVC and aluminum, etc.

base glue: ready-to-use waterproof strong viscose

2. Main Features of Anti-slip Tape

Good impact resistance

Excellent in adhesion

Resistance to cold, heat

Excellent in adhesion and flame retardant

Resistance to age

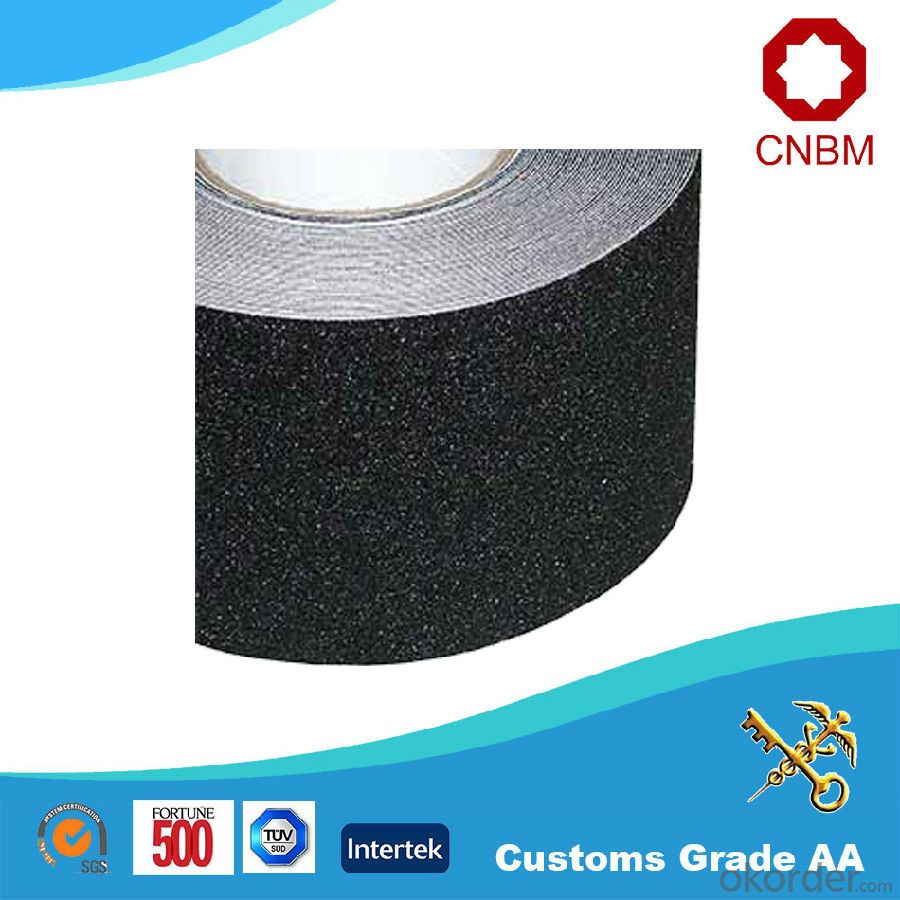

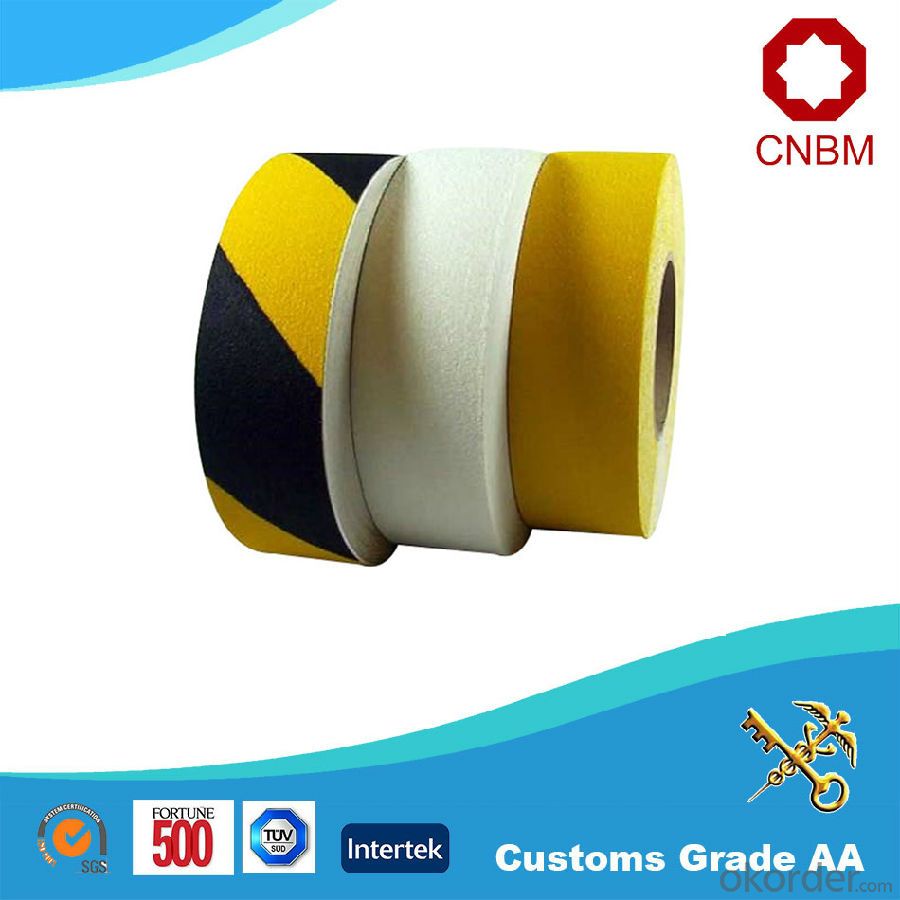

3. Anti-slip Tape Images

4. Anti-slip Tape Description

Item No. | Carrier | Thickness (c) | Anti-skid sand | Surface granularity |

CN-1101 | PVC film | 10 | black corundum | 60 items |

CN-1102 | PVC film | 25 | black corundum | 40 items |

CN-1105 | PVC film | 10 | black corundum | 100 items |

CN-1106 | PET film | 5 | black corundum | 60 items |

CN-1107 | PP film | 5.6 | black corundum | 80 items |

CN-1108 | PET film | 6 | silicon carbide | 50 items |

5. FAQ

Q1. What can we do for you?

Satisfactory sales service

24 hours service for you

Custom-made advices for your need

Your inquiry will be replied within 12 hours.

Professional consultation on your local market

Q2.What are the colors of Anti-slip Tape?

black, gray, red, orange, blue, between yellow and black, red and white, transparent, white, reflective, night light-emitting, etc. printing a variety of beautiful picture and patterns according with customer requirements

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can packaging tape be used for sealing plastic pet carriers?

- Yes, packaging tape can be used for sealing plastic pet carriers. Packaging tape is designed to securely seal boxes and packages, and it provides a strong adhesive bond. When applied properly, it can effectively seal the openings of plastic pet carriers, ensuring that your pet is safely contained inside. However, it is important to ensure that the tape is applied evenly and securely to prevent any gaps or openings that your pet may be able to escape from. Additionally, it is recommended to check the tape periodically to make sure it remains intact and reapply if necessary.

- Q: Is packaging tape heat resistant?

- Yes, packaging tape is generally heat resistant. Most packaging tapes are made from materials such as polypropylene or acrylic, which have high melting points and are able to withstand high temperatures. This heat resistance makes packaging tape suitable for various applications, including sealing boxes and packages that may be subjected to heat during transportation or storage. However, it is important to note that the specific heat resistance of packaging tape may vary depending on the brand and quality of the tape. Therefore, it is recommended to check the product specifications or consult with the manufacturer to ensure that the packaging tape is suitable for the intended use and temperature conditions.

- Q: Can packaging tape be used for sealing glass bottles?

- Yes, packaging tape can be used for sealing glass bottles. However, it is important to note that packaging tape is not designed specifically for sealing glass bottles, so it may not provide the same level of durability and air-tightness as specialized bottle sealing methods. Additionally, the adhesive on packaging tape may not adhere well to glass surfaces, leading to potential leakage or breakage. It is recommended to use proper bottle sealing methods such as cork stoppers, screw caps, or specialized bottle sealing tapes for glass bottles to ensure the best results.

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Packaging tape is indeed suitable for sealing arts and crafts materials. Its versatility as an adhesive enables it to effortlessly attach and secure a wide range of materials such as paper, cardboard, fabric, and more. Whether you need to seal envelopes, wrap gifts, or engage in art projects, packaging tape guarantees a sturdy and durable bond, ensuring the secure sealing of your arts and crafts materials. Moreover, its transparent nature allows it to seamlessly blend with your project, making it an exceptional option for sealing arts and crafts materials.

- Q: Can packaging tape be used for sealing bubble wrap?

- Certainly, bubble wrap can be sealed using packaging tape. Frequently employed as a safeguarding packaging substance for delicate objects, bubble wrap is often secured and sealed with packaging tape. By affixing packaging tape to the edges and joints of the bubble wrap, one can successfully seal it, guaranteeing its integrity during transportation or storage. The adhesive on packaging tape establishes a sturdy connection, assuring that the bubble wrap remains in position and offers supreme protection for the items it envelops.

- Q: How do I prevent packaging tape from yellowing over time?

- To prevent packaging tape from yellowing over time, it is essential to store it in a cool, dry, and dark place. Exposure to sunlight and humidity can accelerate the yellowing process. Additionally, using high-quality packaging tape made from materials resistant to discoloration can help maintain its original appearance for a longer period.

- Q: Buy adhesive tape every time, discover its sticky viscosity is insufficient, encounter cold weather, do not use well,

- Adhesive tape testing methods are mainly1, tack: the test tape is stuck to the initial ability of the adherend size, general method is to use the standard ball into the natural roll tape 45 degree angle on the tilt, increasing the size of the ball, the ball can stick to the greater, the greater initial viscosity

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: Can packaging tape be used for sealing packages with heavy-duty construction materials?

- Indeed, packaging tape possesses the capability to seal packages that encompass robust construction materials. Its purpose lies in furnishing powerful adhesion and endurance, rendering it fitting for the task of safeguarding packages harboring heavy-duty construction materials. Nevertheless, it is of utmost importance to meticulously select a packaging tape exclusively engineered for heavy-duty applications, such as reinforced or exceptionally potent tape, in order to guarantee proper sealing and secure transportation. Moreover, it is prudent to fortify the packaging through the utilization of supplementary tape or protective wrapping, contingent upon the weight and fragility of the construction materials, for the purpose of ensuring a safe and secure delivery.

- Q: What are the common color options for packaging tape?

- The common color options for packaging tape include clear, brown, white, and various shades of blue, red, green, and yellow.

Send your message to us

Brown Gum Anti-Slip Tape with Solvent Based Acrylic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords