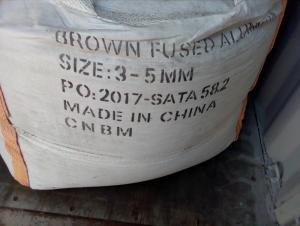

BROWN FUSED ALUMINA FOR REFRACTORY PRODUCTS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

· Place of Origin: Henan, China

· Shape: Block or grain size or powder

· Material: Alumina

· Al2O3:95%min

· SiO2:1.3%max

· TiO2: 3%max

· Fe2O3:0.3%max

· CAO:0.6%max

· MGO:0.3%max

· K2O+Na2O:0.3%max

· B.D:3.8g/cm3min

· MOI:0.2%max

· Refractoriness (Degree):1770°< Refractoriness< 2000°

· Model Number:Customer's Requirement

· Brand Name:CMAX

· Application:Metallurgy and Refractory

· Product name: Brown Fused Alumina

· Color: Brown

· Size:50MESH/100MESH/200MESH/325MESH/0-1MM/1-3MM/3-5MM/0-40MM

· BULK DENSITY:3.8g/cm3min

· Certificate:ISO9001

· Usage:Fire Resistance Place

· Type:Raw Refractory

· Packaging Details:Bags/In bulk/As costomer's requirement'

Quality assurance:

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

FAQ:

Q: What kind of payments does your support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, you only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer.

Q: Do you have other products?

A: Yes, please check our other products in website.

- Q: What is the importance of silicon powder in refractory processing?

- it depends on the type of refractory material, in addition to lS friends talked about, in the amorphous mobility\ strength should also have an impact

- Q: Who knows about the fire endurance of A grade fireproofing glass doors?

- Fire doors and windows are divided into grade A, B and C according to the real national situation, also the minimum fire endurance has been stipulated, namely, the minimum fire endurance of grade A is 1.50 h, that of grade B and C are 1.00 h and 0.50 h respectively. There are wooden fire doors and steel fire doors. The main purpose of it is to reach the time that fire resistance should last. But door?closers are required to install. The fire endurance of A grade wooden fire doors should be no less than 90 min, and that of B grade fire doors should be no less than 60 min, that of C grade fire doors should be no less than 30 min! ! !

- Q: How to divide the fire resistant level of EVB?

- Inorganic materials: Level A incombustible material is mainly divided into three levels, which attributed to two types of materials! Inorganic materials: Rock wool, foam cement, vitrified micro bead, foam glass organic: Eps xps polyurethane phenolic aldehyde, polystyrene particles are divided into two manufacturing techniques including field fabrication and pre-production polyurethane - now sprayed, precast slab eps, xps, phenol - now posted, precast slab (composite board)

- Q: How about the prospect of refractory material?

- Due to the rise of raw material, the prospect is not good with inflation, lower prices and decreased profits. The product requirements have been enhanced and there is vicious competition. Therefore, it is really bad.

- Q: Where is the distributing center of refractory materials in China?

- The construction of Gongyi Chinese refractory chemical industry professional market is a street in Yongan to implement the spirit of the six plenary session of the four session of the Gongyi municipal Party committee, the adjustment of economic structure, an important step in developing the service industry out of the. First, to promote the rapid development of the third industry. Through the improvement of refractory trade logistics system, make Yongan do truly become the first-class refractories trade and logistics center, driven by the refractory industry from the production area to the exhibition, logistics field extension and transformation, become refractory chemical industry center, Yongan office to promote the optimizing and upgrading of economy. Two is to promote intensive land development. Through the integration of resources, the unified planning of the reserved land, intensive development according to the standard of the city, the introduction of powerful investors, construction of large-scale projects. Three is to further create a business atmosphere in Yongan. Refractory chemical professional market operation, will promote the overall development of Yongan to do business, increase the flow of people, logistics, information flow, capital flow, more to promote the rapid development of the third industry in Yongan office.Gongyi Chinese refractory chemical industry professional market completion, will further promote the development of Yongan street service industry, accelerate the pace of economic restructuring, will run the streets of industrial upgrading has played a great role in promoting. Yongan road street is unprecedented high spirited gesture, innovation and development opportunities, so that industrial upgrading and optimization of the pattern to accelerate the realization of, we are convinced that Yongan's tomorrow will be better!

- Q: Who can tell me about the foundry refractory materials?

- The casting fireproof materials can be divided into three categories in accordance with chemical property, namely, acidic, neutral and alkaline refractories. The commonly used refractories are alkaline and neutral ones, such as alkalic magnesia-carbon bricks, fired magnesite bricks, magnesia-chrome bricks, magnesium-calcium bricks, and neutral high alumina bricks, corundum brick, clay bricks, etc. The shapeless ones include: castable refractory, ramming?mass, gunning mix, coating, and dry vibration material, etc!

- Q: What are the construction measures of refractory material in winter? Please descriptive briefly.

- The temperature is low in winter, so refractory bulk materials should be stirred evenly on time to avoid freezing.

- Q: What materials are needed to make the amorphous refractory bricks?

- Amorphous refractory brick is composed of a certain proportion of aggregate and powder, a binder and an additive, and can be directly used without high temperature firing.

- Q: What is the material of fire resistant glass reinforced plastics grating?

- What is the material of fire resistant glass reinforced plastics grating?

- Q: Who can tell me the properties and classification of insulating refractories?

- The refractory materials refers to the refractory material of high porosity, low volume density, low thermal conductivity of the insulating material. Also called lightweight refractories. It includes insulating refractory products, refractory fiber and refractory fiber products.The characteristics of insulating refractory material is of high porosity, generally 40% to 85%; the volume density is low, generally less than 1.5g/cm3; the thermal conductivity is low, generally less than 1.0W (M - K). It is used as the insulation material of industrial furnace, furnace can reduce heat loss, save energy, and reduce thermal insulation equipment weight. The mechanical strength of refractory material, abrasion resistance and slag resistance is poor, should not be used for load-bearing structure of furnace slag, furnace, and direct contact with the molten metal and other parts.

Send your message to us

BROWN FUSED ALUMINA FOR REFRACTORY PRODUCTS

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords