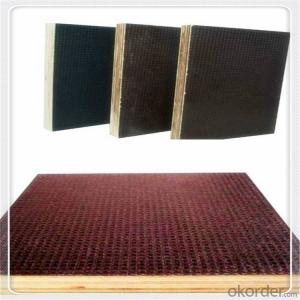

Brown/Black Plywood Subfloor with Hardwood Core - Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

1)Size:1220*2440mm,1250*2500mm

2)Thickness:2.5-30mm

3)Core:poplar,combi,hardwood

4)Glue:MR,WBP,melamine

Plywood Feature

Size | 1220*2440mm,1250*2500mm |

Thickness | 9-25mm |

Core | poplar,combi,hardwood |

Film | Chinese brown,dynea brown,black,red |

Glue | MR,WBP,melamine |

Density | 500-630kgs/cbm |

Moisture | 6-14% |

Thickness tolerance | +/-0.5mm |

Modulus of rupture | ≥30Mpa |

Modulus of Elasticity | ≥6000Mpa |

Packing | inside by 0.2mm plastic bag,outside by carton box and bundled by steel strip |

Advantage

1. Capacity: 6000 CBM per month

2. Sample available

3.High quality and competitive price

4.15 years’ experience in export

- Q: National standards for decorative veneer veneer plywood performance requirements

- China is the recommended standard GB / T 15104-94 "decorative veneer veneer board", the vast majority of enterprises to implement the implementation of this standard

- Q: triple? Nail gun Self-tapping screws? Cork Or other?

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- High-quality urea-formaldehyde glue / melamine glue / phenolic glue can reach E0 level, E1 level, that can be used directly for indoor

- Q: A brief introduction to plywood

- The number of layers is generally odd, and few are even. Vertical and horizontal direction of the physical and mechanical properties of small differences

- Q: What is the difference between plywood glue E0E1?

- Melamine gel: moisture-proof, and has a certain resistance to boiling, weather resistance / can be used for outdoor or indoor, but can not often be water immersion.

- Q: Material for the plywood defects which

- Decay rot due to the invasion of wood rot fungi, the cell wall material decomposition, resulting in loose wood, strength and density decreased, wood tissue and color are often changing.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- . At that time, high-quality furniture, timber supply is sufficient, those who are not beautiful or poor durability of wood used only for non-exposed parts of furniture.

- Q: Plywood in the processing of defects

- sand through sandlng through due to excessive sanding the table, local wear exposed layer or the next layer of veneer

- Q: Why is the plywood commonly used in the singular layer

- and take a vertical put a then put the plastic in the horizontal put a then In the vertical put a piece into a plywood

- Q: What are the plywood specifications?

- structure. The texture of the adjacent veneer should be at right angles; the center layer is symmetrical with respect to the center layer, and the thickness of the layers is the same;

Send your message to us

Brown/Black Plywood Subfloor with Hardwood Core - Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 6000 m³/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords