Geogrids Que Son - Bitumen Coated Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

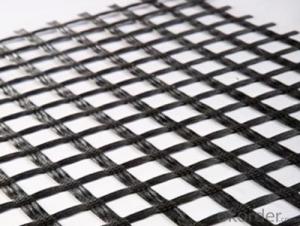

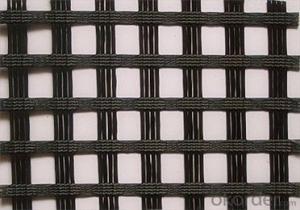

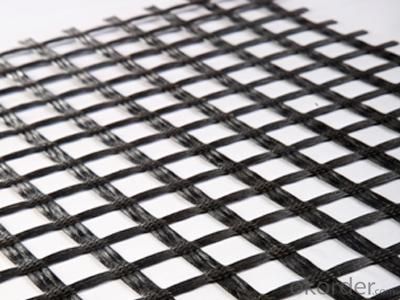

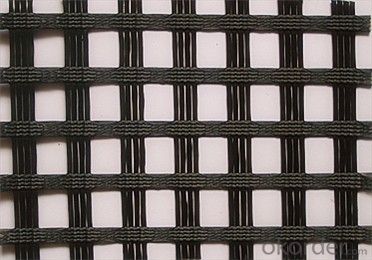

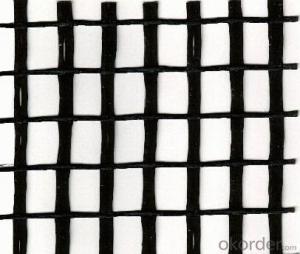

Structure of Bitumen Coated Fiberglass Geogrid Description:

Bitumen Coated Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.Used for engineering reinforcement,10%,13% elongation,50x50mm holes size.

Main Features of Bitumen Coated Fiberglass Geogrid:

Improve roadbed bearing capacity,enlarge road lifetime.

Prevent road collapse and crack

Prevent soil and water loss in slope

Could replace steel-plastic geogrid in coal mine.

Bitumen Coated Fiberglass Geogrid Images

Bitumen Coated Fiberglass Geogrid Specification:

| MODEL | GSZ30 | GSZ40 | GSZ50 | GSZ60 | GSZ70 | GSZ80 | GSZ100 | GSZ125 | GSZ150 |

Limit longitudinal tensile | 30 | 40 | 50 | 60 | 70 | 80 | 100 | 125 | 150 |

Limit longitudinal elongation | 3 | ||||||||

Tensile at 2% of stretch | 23 | 29 | 42 | 51 | 59 | 67 | 84 | 107 | 127 |

Solder joint Peel strength N≥ | |||||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in landfill capping systems?

- Yes, geogrids can be used in landfill capping systems. Geogrids are often used as reinforcement materials in landfill capping systems to enhance stability, prevent erosion, and provide long-term support for the capping layer. They are placed between layers of soil or other materials to improve the overall performance and effectiveness of the landfill capping system.

- Q: Can geogrids be used in reinforcement of bridge abutments on soft clays?

- Yes, geogrids can be used in the reinforcement of bridge abutments on soft clays. Geogrids are commonly used in geotechnical engineering to improve the stability and strength of soil structures. In the case of bridge abutments on soft clays, geogrids can provide lateral reinforcement and enhance the load-bearing capacity of the soil, reducing settlement and improving overall stability.

- Q: The amount of geotextile is estimated to be used on both sides of the retaining wall

- Application of Geogrid in soft soil foundation and uneven settlement

- Q: What are the factors that affect the quality of glass fiber reinforced plastic grid

- Synthetic resin. Synthetic resin is used as the substrate of glass fiber reinforced plastics, which is used to paste the glass fiber into a whole. Because the resin is the base material, it has influence on the elastic modulus, heat resistance, electrical insulation, permeability, chemical corrosion resistance, weather resistance, aging resistance and so on.In addition, the interface is also an important factor affecting quality. The high performance of glass fiber reinforced plastic (FRP) grid cover is related to the quality and durability of the interface between fiber and resin. The interface has a great influence on the performance of glass fiber reinforced plastic grid. As everyone knows, the glass fiber is a cylindrical glass surface, such as glass, smooth, and the surface is often firmly adsorbed with a thin layer of water film, which certainly affect the bonding properties of glass fiber and resin. Especially in textile glass fiber drawing process, in order to achieve the collection, lubrication, eliminate the static, often coated with a layer of wetting agent, the wetting agent is the most paraffin substances remained on the surface of glass fiber on them, the isolation effect on synthetic resin and glass fiber, with both adhesive.

- Q: What are the applications of geogrids in civil engineering?

- Geogrids are extensively used in civil engineering for various applications such as soil stabilization, slope reinforcement, retaining wall construction, and pavement reinforcement. They provide strength and stability to soil structures, prevent erosion, increase load-bearing capacity, and enhance overall structural integrity. Geogrids are also employed in infrastructure projects like road construction, railway tracks, landfill sites, and coastal protection, contributing to the longevity and durability of these civil engineering projects.

- Q: What are the factors that affect the creep behavior of geogrids?

- The factors that affect the creep behavior of geogrids include the type and quality of the material used in the geogrid, the magnitude and duration of the applied load, the environmental conditions such as temperature and moisture, and the installation and construction techniques employed.

- Q: How do geogrids improve the stability of embankments?

- Geogrids improve the stability of embankments by providing reinforcement and enhancing the load-bearing capacity of the soil. They act as a stabilizing element by distributing the applied forces more evenly, reducing soil movement and potential slope failures. The geogrids interlock with the soil particles, creating a stronger and more stable structure that can withstand higher loads and resist deformation.

- Q: What are the specifications of the geogrid for road use?

- Warp knitted grating

- Q: What are the benefits of using geogrids in soil reinforcement?

- There are several benefits of using geogrids in soil reinforcement. Firstly, geogrids provide increased stability to the soil, preventing erosion and soil movement. They distribute and transfer the load more evenly, reducing the risk of soil settlement and subsidence. Additionally, geogrids improve the bearing capacity of the soil, allowing for the construction of structures on weak or unstable ground. They also enhance the long-term performance of the soil by minimizing the impact of environmental factors like freeze-thaw cycles and moisture changes. Overall, geogrids offer cost-effective and sustainable solutions for soil reinforcement projects.

- Q: What are the benefits of using geogrids in construction projects?

- Geogrids offer several benefits in construction projects. Firstly, they provide reinforcement to soil, preventing its movement and improving stability. Secondly, they enhance the load-bearing capacity of the soil, allowing for the construction of structures on weak or unstable ground. Additionally, geogrids help reduce construction costs by eliminating the need for extensive excavation and the use of traditional construction materials. They also facilitate faster construction by reducing the time required for ground preparation. Overall, geogrids enhance the longevity and durability of construction projects while providing cost and time savings.

Send your message to us

Geogrids Que Son - Bitumen Coated Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords