Biaxial PVC Coated Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

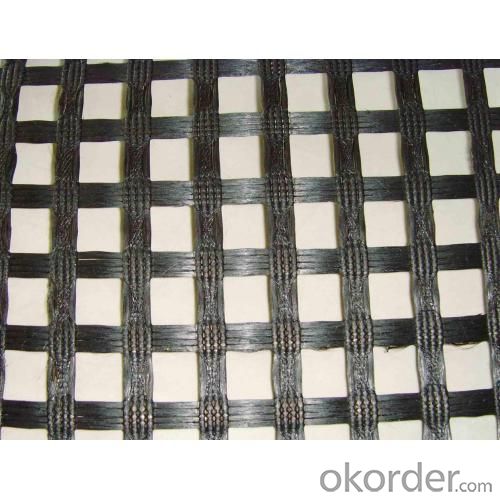

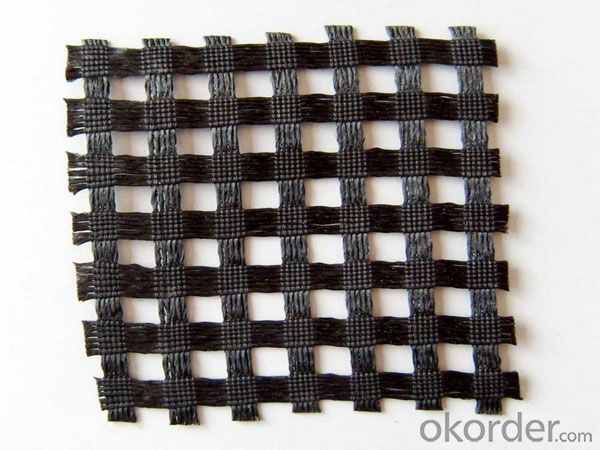

Structure of PVC Coated Geogrid Description:

PVC Coated Geogrid defined as a grid structure of polymeric material formed by weaving or knitting intersecting ribs with appropriate apertures (opening sizes) to allow interlocking with surrounding soil, rock, earth and other surrounding materials. There are two basic categories of geogrids. Uniaxial geogrids designed to endure stress in one direction. Their main strength is in the machine direction making these grids suitable for wall and slope applications.

Main Features of PVC Coated Geogrid

Improving bearing capacity of retaining wall or dam

Extending the project life

Reducing floor area

Shortening construction period, reducing cost and maintaining expense

PVC Coated Geogrid Images

PVC Coated Geogrid Specification:

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 | |

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Are geogrids suitable for use in slope stabilization for mining haul roads?

- Yes, geogrids are suitable for use in slope stabilization for mining haul roads. Geogrids are engineered materials that provide reinforcement and stability to soil, improving its load-bearing capacity. They are commonly used in various applications, including slope stabilization, to prevent soil erosion and maintain the integrity of the road. By distributing the load more evenly and reducing the potential for soil movement, geogrids enhance the safety and durability of mining haul roads.

- Q: What is the main purpose of unidirectional plastic geogrid?Plastic geogrid production

- Unidirectional geogrid reinforced asphalt pavement or cement: Geogrid laying layer at the bottom of asphalt or cement, can reduce rutting depth, prolong the fatigue life of the pavement, but also can reduce the asphalt or cement pavement thickness, in order to save costs.For road slope and dam reinforcement and retaining wall: the traditional embankment especially filling high embankment filling and often need to shoulder edge easy compaction, resulting in slope rainwater invasion, collapse instability phenomena have occurred, but with a gentle slope, covers an area of large, the retaining wall has the same the problem of using geogrid embankment slope or retaining wall reinforcement can be reduced by two points a area, prolong service life, reduce the cost of 20 - 50%.

- Q: How do geogrids prevent soil erosion?

- Geogrids prevent soil erosion by providing reinforcement to the soil, increasing its stability and resistance to external forces such as water flow or wind. The geogrids are typically made of high-strength materials and are placed within the soil, creating a network of interlocking structures that enhance the soil's load-bearing capacity. This prevents the soil from being easily displaced, maintaining its integrity and reducing erosion.

- Q: Can geogrids be used in railway track stabilization?

- Yes, geogrids can be used in railway track stabilization. Geogrids are commonly used in civil engineering projects to improve soil stability, reinforce weak subgrades, and minimize lateral movement. In railway track stabilization, geogrids can be installed beneath the ballast layer to enhance load distribution, reduce track settlement, and increase the overall strength of the track system.

- Q: What are the different materials used to manufacture geogrids?

- Geogrids are manufactured using various materials such as polyester, polypropylene, high-density polyethylene (HDPE), and fiberglass. These materials offer different strengths, durability, and chemical resistances, allowing geogrids to be customized for various applications in civil engineering and construction projects.

- Q: How do geogrids help in reducing the risk of soil erosion?

- Geogrids help in reducing the risk of soil erosion by providing reinforcement to the soil. They are made up of high-strength materials and are designed to be placed within the soil, creating a stable structure. This reinforcement improves the soil's stability, preventing it from being washed away by water or blown away by wind. Geogrids also help to distribute the applied loads more evenly, reducing the potential for localized soil erosion.

- Q: How do geogrids improve the performance of geocell-reinforced slopes for erosion control?

- Geogrids improve the performance of geocell-reinforced slopes for erosion control by providing additional strength and stability. They help distribute the load evenly across the slope, preventing soil movement and reducing erosion. Additionally, geogrids increase the frictional resistance between soil layers, enhancing the overall slope stability and preventing soil slippage.

- Q: How do geogrids improve the performance of unpaved roads?

- Geogrids improve the performance of unpaved roads by enhancing the stability and strength of the road base. They help distribute the load and prevent the lateral movement of soil particles, thereby reducing rutting and potholes. Geogrids also enhance the overall longevity of the road by reducing the need for maintenance and repair, making the road more durable and cost-effective in the long run.

- Q: What is the use of glass fiber grille paving asphalt road

- Fiberglass geogrid is glass fiber as the material, the reticular structure material of the knitting process, for the protection of glass fiber, improve the overall performance of geo composites through a special coating treatment process and the. The main component of glass fiber

- Q: How do geogrids help in reducing the environmental impact of construction?

- Geogrids help in reducing the environmental impact of construction by providing stabilization and reinforcement to the soil, leading to a reduction in the amount of excavation and land disturbance required. This helps to minimize the need for additional resources and materials, as well as the overall carbon footprint of the construction project. Additionally, geogrids can enhance the longevity of structures, reducing the need for frequent repairs or replacements, further minimizing the environmental impact.

Send your message to us

Biaxial PVC Coated Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords