Best Prepainted Galvanized steel Coil JIW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Prepainted Galvanized steel Coil :

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called prepainted galvanized steel ( PPGI) .Prepainted galvanized steel is good capable of decoration ,molding,corrosion resistance The carbon in typical steel alloys may contribute up to 2.1% of its weight. Varying the amount of alloying elements, their formation in the steel either as solute elements, or as precipitated phases, retards the movement of those dislocations that make iron comparatively ductile and weak, and thus controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel's strength compared to pure iron is only possible at the expense of ductility, of which iron has an excess.

2.Main Features of Prepainted Galvanized steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

Although steel had been produced in bloomery furnaces for thousands of years, steel's use expanded extensively after more efficient production methods were devised in the 17th century for blister steel and then crucible steel. With the invention of the Bessemer process in the mid-19th century, a new era of mass-produced steel began. This was followed by Siemens-Martin process and then Gilchrist-Thomas process that refined the quality of steel. With their introductions, mild steel replacedwrought iron.

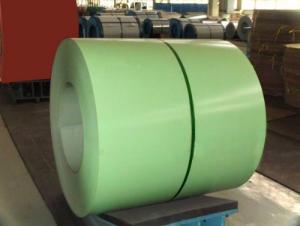

3.Prepainted Galvanized steel Coil Images

4.Prepainted Galvanized steel Coil Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: Are steel strips used in the production of automotive body panels?

- Yes, steel strips are commonly used in the production of automotive body panels. Steel is a durable and cost-effective material that provides strength and structural integrity to the body of a vehicle. Steel strips are often formed, shaped, and welded to create different body panel components such as doors, fenders, hoods, and roofs.

- Q: Can steel strips be used in the production of consumer electronics?

- Yes, steel strips can be used in the production of consumer electronics. Steel strips are commonly used for manufacturing various components such as casings, frames, brackets, and connectors in consumer electronic devices. The steel strips offer durability, strength, and stability, making them suitable for applications in consumer electronics.

- Q: Can steel strips be used in the production of hydraulic systems?

- Yes, steel strips can be used in the production of hydraulic systems. Steel is a commonly used material in the manufacturing of hydraulic systems due to its high strength and durability. Steel strips can be used to construct various components of a hydraulic system, such as cylinders, pistons, valves, and fittings. The use of steel strips ensures that these components can withstand the high pressures and forces associated with hydraulic systems. Additionally, steel is resistant to corrosion and can withstand extreme temperature variations, making it an ideal material for hydraulic applications.

- Q: How are steel strips straightened?

- Leveling or flattening is the method utilized to straighten steel strips. This technique is executed using specialized machinery, namely levelers or flatteners. To initiate the process, the steel strip is introduced into the leveler, which comprises a series of small-diameter rolls arranged consecutively. These rolls are strategically positioned to gradually bend the strip in the opposite direction of its existing curvature. While the steel strip progresses through the leveler, the rolls exert pressure on the convex side of the strip, gradually diminishing its curvature. The number and spacing of the rolls can be adjusted to accommodate various thicknesses and widths of steel strips. In addition to the rolls, levelers may incorporate supplemental features like tension rolls or hydraulic or pneumatic systems to further ensure proper straightening of the steel strip. These additional components aid in applying tension or counteracting any residual stresses in the strip, thereby yielding a straightened final product. In conclusion, the leveling process plays a vital role in guaranteeing the flatness and straightness of steel strips, which is of utmost importance for their subsequent processing and utilization across diverse industries such as automotive, construction, and manufacturing.

- Q: What are the different treatments applied to steel strips for specific applications?

- There are several different treatments that can be applied to steel strips for specific applications. These treatments are designed to enhance the properties of the steel and make it more suitable for its intended use. One common treatment is heat treatment, which involves heating the steel strip to a specific temperature and then cooling it rapidly. This process can be used to improve the hardness, strength, and toughness of the steel. Heat treatment can also be used to alter the microstructure of the steel, which can improve its machinability or resistance to wear. Another treatment commonly applied to steel strips is surface coating. This involves applying a thin layer of another material to the surface of the steel. The coating can provide protection against corrosion, improve the aesthetics of the steel, or enhance its performance in specific environments. Some common types of surface coatings include zinc plating, galvanizing, and powder coating. Some steel strips may also undergo cold rolling or annealing processes. Cold rolling involves passing the steel strip through a series of rollers at room temperature to reduce its thickness and improve its surface finish. Annealing, on the other hand, involves heating the steel strip to a specific temperature and then cooling it slowly to relieve internal stresses and improve its ductility. In addition to these treatments, steel strips can also be subjected to various mechanical processes, such as bending, cutting, or shaping, to achieve the desired dimensions and form. These processes can be performed before or after any of the above treatments, depending on the specific requirements of the application. Overall, the choice of treatment for a steel strip depends on the specific application and the desired properties of the final product. By applying the appropriate treatment, steel strips can be tailored to meet the needs of various industries, such as automotive, construction, and manufacturing.

- Q: Do steel strips come with special certifications or standards?

- Yes, steel strips often come with special certifications or standards to ensure their quality, safety, and compliance with industry requirements. These certifications can include ISO 9001 (quality management system), ISO 14001 (environmental management system), and ISO 45001 (occupational health and safety management system). Additionally, steel strips may also adhere to specific industry standards such as ASTM (American Society for Testing and Materials) or EN (European Norms) to ensure their suitability for various applications.

- Q: What are the recycling options for steel strips?

- Steel strips have various recycling options available. One common choice involves taking them to a scrap metal recycling facility. These facilities collect and sort steel strips, along with other metal items, before processing them for recycling. Typically, the steel strips are melted down, refined, and utilized to create new steel products. Another option is to repurpose steel strips for different applications. For instance, they can be employed in construction projects, serving as reinforcement in concrete structures or components in manufacturing processes. This approach helps decrease the demand for fresh steel and reduces waste. Additionally, individuals or organizations specializing in upcycling or creating artistic pieces from recycled materials may purchase or receive donated steel strips. This enables the transformation of the steel strips into unique and imaginative products, granting them a renewed purpose and existence. In summary, the recycling options for steel strips are varied and provide environmentally-friendly alternatives to simply disposing of them in landfills. By opting to recycle or repurpose steel strips, we can contribute to the conservation of natural resources, reduce energy consumption, and minimize the environmental impact of steel production.

- Q: How are steel strips used in the production of electronics?

- The production of electronics relies on the utilization of steel strips in various manners. One prevalent application involves their use in the manufacturing process of printed circuit boards (PCBs). These PCBs are essential elements within electronic devices as they serve as platforms for the mounting and interconnecting of diverse electronic components. By serving as a base material, steel strips offer stability and support to the PCBs. Additionally, electronic enclosures also employ steel strips during production. These enclosures act as protective housing for the internal components of electronic devices, shielding them from external factors including dust, moisture, and physical harm. Steel strips are frequently employed in constructing the frames or outer shells of these enclosures, guaranteeing both strength and durability. Moreover, connectors and terminals, vital for establishing connections between different parts of electronic devices such as cables, wires, and circuit boards, rely on steel strips during production. By utilizing steel strips, manufacturers are able to create reliable and robust connections, ensuring the efficient transmission of electrical signals. In conclusion, steel strips assume a pivotal role in the production of electronics by acting as a base material for PCBs, providing structural support to electronic enclosures, and enabling the creation of connectors and terminals. Their durability, strength, and conductivity make them an indispensable component within the manufacturing process of electronic devices.

- Q: How are steel strips cut into specific lengths?

- Steel strips are cut into specific lengths using various methods and tools. One of the most common methods is using a shear, which is a machine specifically designed to cut through metal. The steel strip is placed in the shear, and the shear's blades are then activated to cut through the strip, resulting in the desired length. Another method is using a saw, such as a circular saw or a band saw. These saws are equipped with sharp, toothed blades that can easily cut through steel. The steel strip is secured in place, and the saw is then used to cut through the strip, creating the desired length. Some advanced methods involve using laser cutting or plasma cutting technology. Laser cutting uses a high-powered laser beam to melt or vaporize the steel along the desired cutting line, resulting in a precise and clean cut. Plasma cutting, on the other hand, uses a jet of ionized gas to heat and melt the steel, allowing it to be easily cut into specific lengths. Regardless of the method used, it is crucial to have accurate measurements and precise control over the cutting process to ensure the steel strips are cut into the desired lengths.

- Q: How are steel strips protected against rust and corrosion?

- Steel strips are protected against rust and corrosion through various methods such as applying coatings, galvanizing, or using corrosion inhibitors. These protective measures create a barrier between the steel surface and the external environment, preventing moisture and oxygen from coming into contact with the metal and causing corrosion.

Send your message to us

Best Prepainted Galvanized steel Coil JIW

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 11 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords