Automatic Deduction Cans Molding Machine for Can Makers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

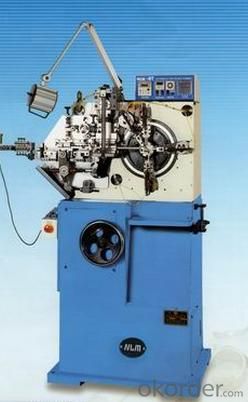

Automatic Deduction Cans Molding Machine for Can Makers

1. Product Description:

The deduction manually punching machine has good quality, easy operation and favorable price. It could be used for sealing the T-shirt bag, sausage, ham and so on. cans.

2. Product Features:

Automatic eyelet machine

High quality, easy operation

Fast speed, auto

Central lubrication system

Easy adjustment, no need touch screen single action

3. Product Parameters:

Model | DK |

Capacity fasteners | 220V/380V 50Hz |

Buckle model | U 506 |

Dimension | 4200×1600×7700mm |

4. FAQ:

Q1: What is your delivery time?

A: Generally, the delivery time is 45-60 days after receive the deposit, big production line may take more time.

Q2: What is the payment term?

A: We accept both T/T and L/C. Most customers pay by T/T.

Q3: What kind of after-sevices do you provide?

A: If it is not big problem, we can solve it by emails, phone etc. If it can’t work, our engineers can go to overseas to install and adjust the machine and solve the problems.

5. Product Pictures:

- Q: Carton packaging in the form of technology, including several major categories

- Raw material is pulp, general corrugated paper, more used for holding items, recyclable. Packaging of paper products is the largest quantity used in packaging industry. Carton is the most important form of transport packaging, and cartons are widely used as food, pharmaceutical, electronic and other products for sale and packaging. With the change of the mode of transportation and sale mode change, carton, carton style diversification, almost every kind of non-standard cartons are accompanied by a set of automation equipment, and the novel carton itself, has become a commodity promotion means

- Q: Vacuum plastic forming process is a kind of thermoforming processing method

- By means of the pressure difference or mechanical pressure on both sides of the sheet, it is deformed and coated on a particular mold surface, cooled, shaped, trimmed and trimmed

- Q: How much is the gas consumption per EPS molding machine per hour?

- You ask this too layman, that is, someone is not accurate to provide, and this is mainly related to the mold. Large gas consumption of mould.

- Q: Plastic packing bag sealing, 3 sides forming, sealing and 4 sides sealing what does that mean?

- If you heat it on both sides of the bag, it is the three side seal. If the sides of the bag are all sealed, it is four sides. Don't understand, you can ask.

- Q: What are the features of carton packaging machines? Introduce concretely

- According to the product line can be divided into: carton forming machine, carton forming machine, packing machine, box machine, paper carton machine, unloading machine, etc..According to the degree of automation of the machine can be divided into: automatic forming machine, automatic carton forming machine, etc..

- Q: What kind of equipment do you need for washing powder packaging bags, a production line, starting from the membrane, what kind of blowing machine, etc., and finally formed into washing powder packaging bags

- Inside is the PE, this is the simplest structure, raw materials can be purchased directly

- Q: Would you like to ask what is the difference between a cold stamping foil and a plain foil wrapper?

- 4., with metallic luster, light shielding, light reflection ability, luminous rate of 95%5., not easy to corrosion, barrier good, moisture-proof, waterproof, airtight, and has fragrant incense6. high temperature and low temperature stable shape, temperature [1] expansion in -73~371 ~ C deformation

- Q: How are plastic products formed?

- The molding process of plastic products, is not only to obtain the desired product, but also improve the plastic properties for thermoplastic and thermosetting plastics, its forming method is not the same, there are several forming methods commonly used.

- Q: Ask: how to improve the strength of PP sheet, used to absorb the molding of the coil, need to meet the requirements of food packaging, and food direct contact.

- In fact, to PP inside copolymerization PE, specifically to find suppliers and resin raw materials suppliers talk about.

- Q: What are the characteristics of plastic thermoforming?

- Mold manufacturing convenient. Hot forming mould has the advantages of simple structure, low cost of material, easy manufacturing and processing, high requirements for materials and manufacturing, and easy to modify, can be made of Gun C Muki S and other materials, the cost is only 1/10 of the injection mold, and the product design changing quickly, suitable for small batch production of parts.5.The production efficiency is high. When using multimode production, the output can reach hundreds of pieces per minute,.6.The utilization rate of waste material is high

Send your message to us

Automatic Deduction Cans Molding Machine for Can Makers

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches