Aluminum Full Skin Sheets - Aluminium Coil with Best Stocks Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

cold drawn and cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series,6000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1050, 1100,1060,2024, 3003, 3105, 5052,5754,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,F,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

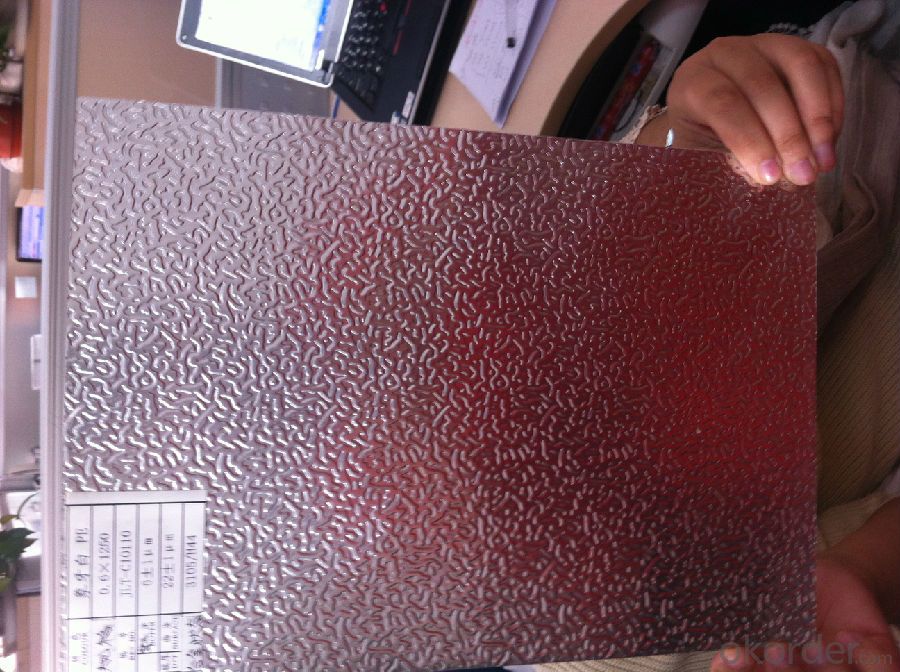

3. Image.

4. Product detailed sizes:

1220mm*2440mm,1219mm*2438mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 300mm to 2500mm, etc.

What is the length range:

---It is from 500mm to 6000mm, etc.

---Normally it is around 2 tons/each size.

How many tons did you export in one year?

Where is your client from?

---Normally it is from bangladesh, fiji, SRI LANKA,uae,Saudi Arabia,

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium checkered sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: This question asks for methods to prevent rusting on aluminum sheets during the installation process.

- <p>To prevent rusting on aluminum sheets during installation, ensure that the aluminum is of high quality and free from impurities. Keep the surface clean and dry at all times, avoiding contact with corrosive materials. Use appropriate protective coatings or sealants that are compatible with aluminum. Avoid scratches or dents that can expose the metal to moisture. Store aluminum sheets in a dry place before installation. During installation, handle the sheets carefully to avoid damage. Regularly inspect and maintain the aluminum sheets to catch any signs of corrosion early.</p>

- Q: How does aluminum sheet perform in high-pressure applications?

- Aluminum sheet performs well in high-pressure applications due to its high strength-to-weight ratio and excellent corrosion resistance. It can withstand elevated pressures without deforming or rupturing, making it a reliable choice for various industries such as aerospace, automotive, and marine.

- Q: What are the typical thickness options for aluminum sheets?

- The typical thickness options for aluminum sheets range from 0.006 inches to 0.25 inches, depending on the specific application and requirements.

- Q: Should I purchase a camper made out of aluminum/wood or a fiberglass?I'm looking to purchase a small camper, approx 18', to tow on the back of my SUV. It's a 2011 Wildwood camper. However, I hear campers made out of aluminum and wood aren't very good because the wood can ruin in time and the aluminum can rust, etc. I hear fiberglass campers are better? Anyone have any knowledge or experience with this? Also, any thoughts or advice with brands/models? And about the Wildwood? Thanks in advance.

- Aluminum is lighter so it offers economies over the life of the trailer. The Airstream has been built almost as long as I've been around. It is true that the wood does rot And some care is needed to stop the occasional leak. Fiberglass is heaver and has it's own maintenance issues. I've no experience with the Wildwood. What I do know is that motor homes are dirt cheap right now. You might think about taking advantage of the economy and pick-up a motor home at a bargain.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum size of aluminum sheets can differ based on the manufacturer and specific use. Nonetheless, as a rule, aluminum sheets typically have a standard maximum size of 4 feet by 12 feet (48 inches by 144 inches). This size is widely employed across industries like construction, automotive, and aerospace. Nevertheless, it is crucial to acknowledge that certain suppliers may offer larger sizes upon request, albeit with additional expenses and factors to consider.

- Q: Are the aluminum sheets suitable for HVAC (heating, ventilation, and air conditioning) applications?

- Aluminum sheets are indeed suitable for HVAC applications, as they possess excellent thermal conductivity, corrosion resistance, and are lightweight. The HVAC industry widely favors aluminum due to these attributes. In HVAC systems, these sheets find common use in ductwork, heat exchangers, and air handling units. When it comes to heating applications, aluminum sheets efficiently transfer heat and can withstand high temperatures. Moreover, their resistance to corrosion ensures long-term durability, particularly in moist environments like air conditioning systems. Furthermore, the lightweight nature of aluminum sheets simplifies installation and reduces the overall weight of HVAC equipment. Overall, aluminum sheets prove to be a reliable and versatile material for various HVAC applications.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation to some extent. While aluminum is not the best material for soundproofing compared to others like rubber or foam, it can still provide some level of sound insulation when used correctly. Aluminum sheets can be installed as a barrier or partition in walls, ceilings, floors, or other surfaces to reduce the transmission of sound waves. However, it is important to note that additional soundproofing materials or techniques might be necessary to achieve optimal results.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- www.okorder /.. its doesnt burn burn u knw.it just becomes sorta britte.it becomes oxidised...u can got more infro there.try..i read it just now

- Q: A 0.2412 gram sample of aluminum ore was dissolved in a dilute mineral acid. The solution was treated with an excess of sodium oxalate. The resultant aluminum oxalate precipitate was filtered, washed and redissolved in mineral acid, then titrated with 42.12 mL of 0.1098 N KMnO4. Calculate the percent of aluminum in the sample.

- 4Al + 6Na2(C2O4) ---- 2Al2(C2O4)3 + 6KMnO4 ---- 3K2(C2O4) Aluminum oxalate and potassium permanganate are at a 1:3 ratio.... Moles of KMnO4 C = 0.1098 mol/L v = 42.12 ml = 0.04212 L C = n/v n= CV = 0.004624776 mols Therefore moles of aluminum oxylate = 0.001541592 mol = moles of aluminum m= 26.98 g/mol * moles mass of aluminum in oxylate = 0.04159215 g % of initial sample = mass of aluminum / mass of ore = 17.24% aluminum in ore sample Perhaps check my math but the method is for sure correct.

- Q: What are the different surface treatments available for aluminum sheets?

- Aluminum sheets have several surface treatment options, each with its own unique properties and advantages. Anodizing, painting, powder coating, and laminating are some of the most commonly used methods. Anodizing, a popular technique, involves immersing the aluminum sheet in an electrolyte solution and passing an electric current through it. This creates a protective oxide layer on the surface, enhancing corrosion resistance, durability, and offering decorative finishes in various colors. Painting is another frequently chosen treatment. It involves applying a layer of paint to the sheet, improving aesthetics and providing protection against corrosion and environmental factors. Painting allows for a wide range of colors and finishes, making it versatile for different applications. Powder coating is an electrostatic process where a dry powder is applied to the aluminum sheet and then cured under heat. This creates a durable and attractive finish with excellent resistance to weathering, chemicals, and UV rays. It offers a variety of color options, textures, and finishes suitable for outdoor use. Laminating involves bonding a thin layer of a different material, like plastic or wood, onto the aluminum sheet. This enhances aesthetics and provides additional properties such as scratch resistance, increased strength, and insulation. Laminating offers a wide range of finishes and textures, allowing for customization and design versatility. These examples demonstrate the various surface treatments available for aluminum sheets. The choice of treatment depends on specific application requirements, desired aesthetics, durability, and environmental factors. Seeking guidance from a professional or supplier can assist in determining the most suitable surface treatment option for a particular project or application.

Send your message to us

Aluminum Full Skin Sheets - Aluminium Coil with Best Stocks Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords