Aluminum Cookware Pressure Cooker Circle Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminum Circle Sheet for Cookware Pressure Cooker Description

• Product: Aluminim Circle

• Application: It is used in cookware, engineering, lighting purpose, fried pans, non-sticky pans, cooking pots, kettles, hard anodize cook wire, pressure cooker and house hold utensils, reflector of the light, etc

• Advantage: Deep drawing and hard anodizing quality Aluminum Circle Sheet can be supplied. Our Aluminum Circle is RoHS and REACH compliance and uses well-protected packing. Our circles are excellent material for producing cookware, utensil, pots, pans and kettles.

2.Main Features of the Aluminum Circle Sheet for Cookware Pressure Cooker

• High manufacturing accuracy

• Smooth surface

• No waves

• High strength of extension and yield

• Well packaged

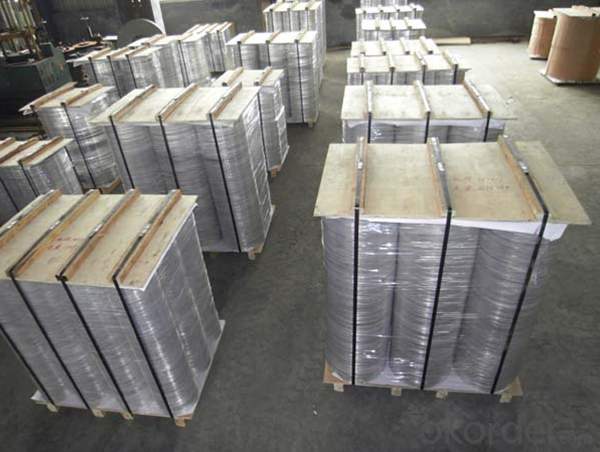

3.Aluminum Circle Sheet for Cookware Pressure Cooker Images

4.Aluminum Circle Sheet for Cookware Pressure Cooker Specification

Alloy | AA1050,AA1060,AA1100 AA3003etc. |

Temper | O,H14 |

Thickness | 0.5MM-4MM |

Diagonal | 100-1200MM |

Standard | GB/T 3880-2006 |

5.FAQ of Aluminum Circle Sheet for Cookware Pressure Cooker

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: This question asks for the common uses of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight, corrosion resistance, and affordability. It's found in beverage cans, food packaging, and cookware. Aluminum is also used in construction for window frames, doors, and roofing. In transportation, it's utilized in the manufacturing of vehicles, aircraft, and ships due to its strength-to-weight ratio. Additionally, it's present in electronic devices, such as smartphones and laptops, for casings and heat sinks. Other applications include electrical wiring, sports equipment, and everyday items like foil and aluminum foil containers.</p>

- Q: What characteristics distinguish pure aluminum from its alloyed forms?

- <p>Pure aluminum is a soft, lightweight, and highly malleable metal with good electrical and thermal conductivity. It is often used for its corrosion resistance and is relatively inexpensive. Aluminum alloys, on the other hand, are made by combining aluminum with other elements like copper, magnesium, silicon, or zinc to enhance its properties. These alloys are stronger, more durable, and can be tailored for specific applications, such as in aerospace, automotive, or construction. They offer improved strength-to-weight ratios, better resistance to heat and wear, and can be anodized for enhanced surface properties. While pure aluminum is more ductile and easier to weld, aluminum alloys provide greater versatility in terms of mechanical properties and performance.</p>

- Q: Is it possible to utilize recycled aluminum in the production of new products more efficiently than current methods?

- <p>Yes, recycled aluminum can be used more effectively in new products than before. Advances in recycling technology have made it easier to purify and refine aluminum from various sources, including post-consumer waste. This not only conserves natural resources but also reduces energy consumption compared to mining and processing raw bauxite. Additionally, the circular economy approach promotes the design of products that are easier to disassemble and recycle, further enhancing the efficiency of using recycled aluminum in new products.</p>

- Q: Is it possible to utilize aluminum in the construction of automobiles?

- <p>Yes, aluminum is widely used in automobiles due to its lightweight, high strength, and excellent corrosion resistance. It is commonly found in engine components, body panels, and wheels. The use of aluminum can lead to reduced vehicle weight, which improves fuel efficiency and reduces emissions. Additionally, aluminum's recyclability makes it an environmentally friendly choice for automotive manufacturing.</p>

- Q: Is it possible to utilize aluminum as a material for automotive construction?

- <p>Yes, aluminum is commonly used in cars. It is valued for its lightweight properties, which can improve fuel efficiency and reduce emissions. Aluminum is used in various parts of a vehicle, including engine components, body panels, and suspension systems. Its high strength-to-weight ratio and resistance to corrosion make it an ideal material for automotive applications.</p>

- Q: This question asks for various methods that can be used to recycle aluminum.

- <p>Recycling aluminum can be done through several methods, including mechanical recycling, which involves melting and reprocessing aluminum without altering its chemical properties. This is the most common method due to its efficiency and cost-effectiveness. Another method is chemical recycling, where aluminum is treated with chemicals to break it down into its constituent elements, which can then be repurposed. Additionally, aluminum can be recycled through a process called hydrometallurgical recycling, which uses aqueous solutions to extract aluminum from waste. Finally, sorting and collection play a crucial role in ensuring that aluminum waste is directed to appropriate recycling facilities where these methods can be applied.</p>

- Q: What are the differences between Aluminum Oxide and Aluminum Alloy in terms of their properties and applications?

- <p>Aluminum Oxide and Aluminum Alloy are distinct materials with different properties and uses. Aluminum Oxide, also known as alumina, is a ceramic material with a high melting point, hardness, and electrical insulation properties. It's used in abrasives, electronics, and as a refractory material. In contrast, Aluminum Alloys are composites of aluminum with other elements like copper, magnesium, or silicon, which enhance their strength, corrosion resistance, and malleability. They are widely used in construction, automotive, aerospace, and packaging due to their lightweight and durability.</p>

- Q: This question asks about the potential health consequences of being exposed to high levels of aluminum.

- <p>Excessive aluminum exposure can lead to various health effects. It has been linked to neurological disorders, including Alzheimer's disease, as it may accumulate in the brain and disrupt normal function. It can also cause bone diseases by interfering with calcium absorption, leading to osteomalacia and osteoporosis. Gastrointestinal issues such as constipation, colic, and even ulcers may arise due to aluminum's impact on the digestive system. Additionally, aluminum exposure has been associated with anemia, as it can inhibit the absorption of iron. While the extent of aluminum's toxicity is still a subject of debate, it is generally advised to minimize exposure to high levels of aluminum to avoid potential health risks.</p>

- Q: Explain the various applications of aluminum in the construction industry.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and corrosion resistance. It's utilized in window frames, doors, curtain walls, and roofing systems for its durability and energy efficiency. Aluminum's malleability allows it to be shaped into various forms, making it ideal for facades and decorative elements. It's also used in structural components like beams and columns, and in electrical wiring due to its excellent conductivity. Additionally, aluminum's sustainability makes it a preferred choice in green building practices, as it's recyclable and has a low environmental impact.</p>

- Q: This question asks for the specific temperature at which aluminum changes from a solid to a liquid state.

- <p>The melting point of aluminum is approximately 660.32 degrees Celsius (1220.58 degrees Fahrenheit). This is the temperature at which solid aluminum begins to melt and transform into a liquid state.</p>

Send your message to us

Aluminum Cookware Pressure Cooker Circle Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords