Aluminum Transition Strips for Aluminum Coil in Roll Shutter with Different Features and Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

Aluminum is a light-weight metal with a bright silvery luster. Small amounts of other metals are added to aluminum to make harder alloys for most uses. Its affinity for oxygen makes it resistant to corrosion and attack by most chemicals. Most aluminum used in visible parts of appliances is lacquered or otherwise coated, anodized or painted.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

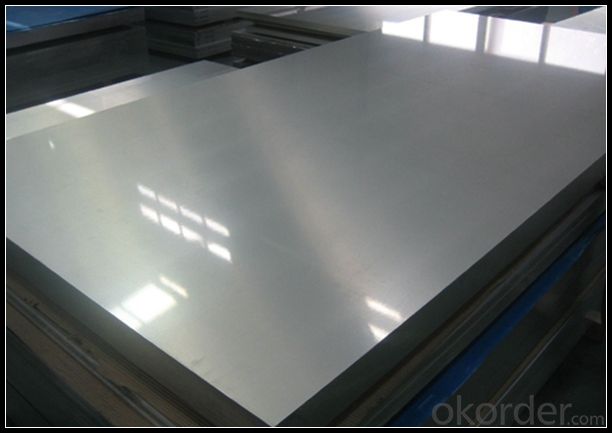

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Why is the president of aluminum strip mildew, will affect the performance of the transformer?

- Can test the resistance, running temperature and other indicators, and the provisions of the comparison.

- Q: This question asks for the cost involved in the production of aluminum strips.

- <p>The cost of aluminum strip production varies significantly and depends on several factors including the cost of raw materials, energy costs, labor, machinery, and market demand. Additionally, the cost can be influenced by the scale of production, efficiency of the production process, and the specific grade or alloy of aluminum used. As of 2023, the cost of aluminum on the London Metal Exchange (LME) is a key factor, as it represents the base price for aluminum. However, to get an accurate cost for aluminum strip production, one would need to consider all these variables and possibly consult with industry-specific cost analysis or directly with aluminum producers for the most current and detailed figures.</p>

- Q: Explain the distinctions between aluminum sheets and aluminum strips.

- <p>Aluminum sheets and aluminum strips are both flat aluminum products, but they differ in width and thickness. Aluminum sheets are wider and can range from 0.2mm to 500mm in thickness, suitable for applications requiring broad surfaces like construction and packaging. Aluminum strips, on the other hand, are narrower and typically used in applications that require thin, elongated pieces, such as in electrical conduits or mechanical parts. The production processes may also vary, with sheets often being rolled and strips being extruded or rolled as well, depending on the specific application and desired properties.</p>

- Q: What are the potential dangers or issues that could arise from using nails or screws to attach aluminum strips?

- <p>There are several risks involved with using nails or screws to install aluminum strips. These include damaging the aluminum strip by causing dents or cracks, especially if the material is thin. There's also the risk of stripping the screw hole, which can weaken the hold and cause the strip to come loose. Additionally, if the aluminum strip is not properly secured, it may lead to accidents or injuries due to falling or improper installation. Using the wrong type of fastener can also lead to corrosion or other material compatibility issues. It's crucial to use the appropriate tools and techniques to minimize these risks.</p>

- Q: Is it possible to substitute metal sheets for asphalt shingles on a roof?

- <p>Yes, you can use metal sheets to replace asphalt shingles on your roof. Metal roofing is a durable and weather-resistant alternative to asphalt shingles. It offers benefits such as longevity, energy efficiency, and low maintenance. However, it's essential to consider the weight of metal sheets compared to shingles, as it may require structural reinforcement. Additionally, proper installation by a professional is crucial to ensure the roof's integrity and to maximize the benefits of metal roofing.</p>

- Q: This question asks for advice on choosing high-quality aluminum strip roofing materials.

- <p>When selecting quality aluminum strip roofing materials, consider the following tips: 1. Gauge Thickness: Opt for a thicker gauge for increased durability and resistance to weathering. 2. Coating: Look for materials with a protective coating, such as Kynar 500 or Hylar 5000, which offer superior resistance to fading and chalking. 3. Color Options: Choose materials with a wide range of color options to match your home's aesthetic. 4. Energy Efficiency: Select materials with high solar reflectance to reduce cooling costs. 5. Manufacturer Reputation: Research the reputation of the manufacturer for quality and reliability. 6. Certifications: Ensure the materials meet industry standards and certifications, such as the American Society for Testing and Materials (ASTM). 7. Warranty: A good warranty is a sign of confidence in the product's quality and longevity. 8. Installation: Consider the ease of installation and whether the material requires specialized tools or techniques.</p>

- Q: Is it possible to recycle aluminum strips more than once?

- <p>Yes, aluminum strips can be recycled multiple times. Recycling aluminum is an efficient process that retains much of the metal's original properties, allowing it to be reused in various applications. The recycling process reduces energy consumption and environmental impact compared to producing aluminum from raw materials. Each time aluminum is recycled, it can be remelted and reformed without significant loss in quality, making it one of the most sustainable materials for recycling.</p>

- Q: Does aluminum maintain its properties and resist damage from fire?

- <p>Aluminum strips are relatively fire-resistant, but not completely immune to damage. Aluminum has a high melting point of approximately 660掳C (1220掳F), which means it can withstand high temperatures without melting. However, it can still oxidize and corrode at elevated temperatures, leading to a loss of structural integrity over time. While it may not catch fire, it can still be affected by prolonged exposure to fire, and its performance can degrade depending on the specific conditions and the protective measures in place.</p>

- Q: What are the specific types of aluminum strips that are frequently utilized in the construction industry?

- <p>Yes, there are several special types of aluminum strips commonly used in construction. These include aluminum flashing strips for waterproofing and sealing, aluminum trim strips for finishing edges and corners, and aluminum heat sinks for heat dissipation in electrical installations. Additionally, aluminum strips are used in curtain wall systems, window frames, and as reinforcement in concrete structures. The choice of aluminum strip depends on the specific requirements of the construction project, such as strength, durability, and resistance to corrosion.</p>

- Q: What are the potential drawbacks or negative aspects of utilizing aluminum strips as a material for exterior siding on a building?

- <p>Aluminum siding, while durable and lightweight, has several disadvantages. It can dent easily due to its softness, which may require frequent repairs. It also lacks insulating properties, leading to increased energy costs as it doesn't retain heat well. Additionally, aluminum siding can be noisy during heavy rain or hail, and it may expand and contract with temperature changes, causing warping or gaps. Furthermore, it can be more expensive than some other materials, and its reflective nature may lead to a less aesthetically pleasing appearance compared to other siding options.</p>

Send your message to us

Aluminum Transition Strips for Aluminum Coil in Roll Shutter with Different Features and Specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords