Non-Stick Round Aluminum Circle Disc DC/CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

1000 Series,3000 Series

Surface Treatment:

Anodized,Polished,Mill Finish

Shape:

Round,Flat

Temper:

O-H112,Soft,Half Hard

Application:

Kitchen Use

Technique:

DC/CC

Thickness:

0.05-4.0mm

Width:

200mm---980mm

Packaging:

Wooden pallets

Non-Stick Round Aluminum Circle Disc DC/CC

Packaging & Delivery

| Packaging Details: | 25kg/carton-boxes(35*32*19CM) &Fumigation wooden-pallets (110*110*15cm) 20GP can loading 22 Ton,total 21 pallets,20 CBM. |

| Delivery Detail: | within 25 days |

Specifications

| Product Name | Aluminium circle/disc/disk |

| Surface | Mill finish &Non stick coated, no scratches,no burrs, withour rough selvedge |

| Alloy | 1100/1050/1060/1070/1200/1350 3003/3004/3104/3005/3105 5005/5052/5454 |

| Temper | HO,H12,H14,H16,H18,H19,H22,H24,H26,H28,F,H112,ect |

| Process | Hot rolled &Cold rolled |

| Thickness | 0.4mm-10.0mm |

| Diameter | 60mm-1200mm |

| Package | Export wooden pallents, craft paper, anti-blushing agent. |

| Payment terms | T/T, L/C,D/P etc |

| Delivery Time | 20-30 days after deposit |

| Quality of material | Totally free from defects like white rust, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set. |

Pictures

About our company:

We are group company, have been listed in Fortune Global 500 for 12 consecutive year.

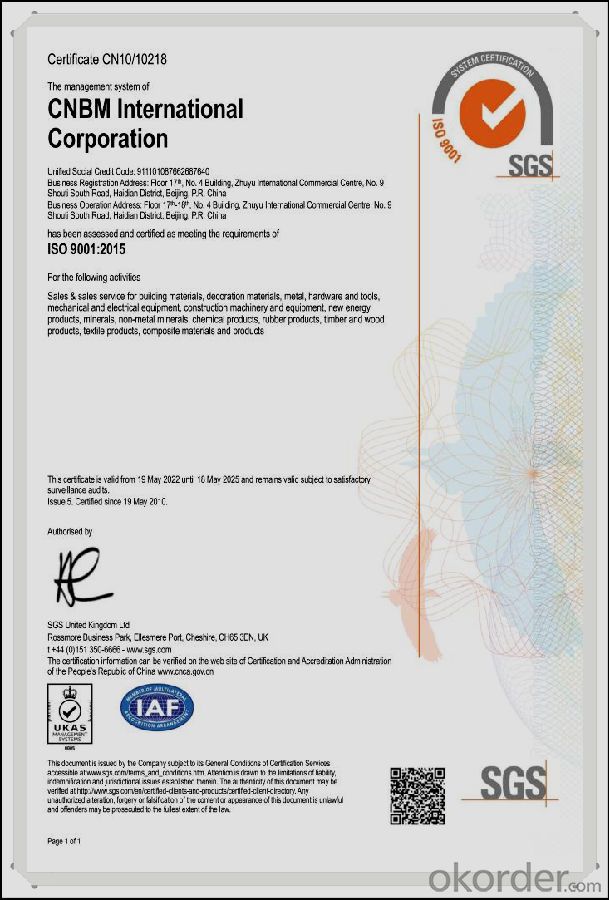

ISO certified

DUNS certified

- Q: This question asks for a comparison of the pros and cons of using aluminum sheets as a roofing material.

- <p>Advantages of using aluminum sheets for roofing include their lightweight nature, which reduces structural load; corrosion resistance, making them suitable for coastal areas; and low maintenance requirements. They are also energy-efficient, reflecting heat and reducing cooling costs. Disadvantages include the potential for dents and damage from hail or heavy impacts, and they can be more expensive than some other roofing materials. Additionally, aluminum can be noisy during rain, and it may require more frequent replacement compared to some other materials due to its lighter gauge.</p>

- Q: Explain how aluminum production and use contribute to global warming.

- <p>Aluminum production contributes to global warming through the emission of greenhouse gases, primarily carbon dioxide. The process of smelting aluminum from bauxite ore is energy-intensive, often relying on fossil fuels, which release CO2. Additionally, aluminum production generates perfluorocarbons (PFCs), potent greenhouse gases. The use of aluminum in various industries and products also has an indirect impact, as it drives demand for energy and resources. Furthermore, aluminum's longevity in landfills means it doesn't decompose, contributing to waste issues and indirectly affecting global warming through methane emissions from landfills.</p>

- Q: Is aluminum a suitable material for manufacturing bicycles and other lightweight vehicles?

- <p>Yes, aluminum is a popular material for making bicycles and other lightweight vehicles due to its high strength-to-weight ratio. It is lightweight, durable, and resistant to corrosion, which makes it an excellent choice for components that need to be strong yet not add excessive weight. Aluminum frames are commonly used in bicycles because they offer a good balance between weight, stiffness, and cost. Additionally, aluminum is widely used in the manufacturing of other lightweight vehicles such as electric scooters, small cars, and even aircraft due to its favorable properties.</p>

- Q: Is it possible to use pure aluminum to create tools and equipment with increased longevity?

- <p>Pure aluminum is not typically used for making tools and equipment that require durability and strength. While it is lightweight and corrosion-resistant, pure aluminum is relatively soft and lacks the strength needed for most tools and equipment. Alloys of aluminum, which combine aluminum with other elements like copper, magnesium, or silicon, are often used instead. These alloys offer improved strength, hardness, and wear resistance, making them more suitable for long-lasting tools and equipment.</p>

- Q: Is it possible to utilize aluminum in the manufacturing of medical devices like stents or implants?

- <p>Aluminum is not typically used in medical devices such as stents or implants due to its potential toxicity and lack of biocompatibility. Medical-grade materials like stainless steel, titanium, and various biocompatible polymers are preferred for their strength, durability, and ability to be safely integrated with human tissues. Aluminum can cause adverse reactions in the body, and its use in medical devices is generally avoided to prevent such complications.</p>

- Q: This question asks for an overview of the environmental effects resulting from the production of aluminum.

- <p>Aluminum production has several significant environmental impacts. The process is energy-intensive, contributing to high greenhouse gas emissions, primarily CO2, which exacerbates climate change. It also generates hazardous waste, such as red mud, a byproduct rich in alkaline and heavy metals that can contaminate soil and water if not properly managed. Air pollution is another concern, with emissions of particulates and sulfur dioxide affecting air quality. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction, impacting biodiversity. Water usage in the production process is substantial, which can strain local water resources. Lastly, the release of fluoride compounds can have detrimental effects on human health and the environment.</p>

- Q: Is it possible to use aluminum as a material for manufacturing stents used in heart surgery?

- <p>Aluminum is not typically used to make stents for heart surgery. Stents are usually made from materials like stainless steel, cobalt-chromium alloys, or platinum-chromium alloys due to their strength, flexibility, and biocompatibility. These materials can withstand the mechanical stress within the body and are less likely to cause adverse reactions. Aluminum, while lightweight and corrosion-resistant, lacks the necessary strength and biocompatibility properties required for long-term implantation in the human body, particularly in critical applications like heart stents.</p>

- Q: This question asks about the methods and steps involved in processing aluminum.

- <p>Aluminum processing involves several key steps: extraction from bauxite ore, refining, and fabrication. Initially, bauxite is mined and then processed to remove impurities. The Bayer process is commonly used to extract alumina (aluminum oxide) from bauxite by dissolving it in a caustic soda solution. The alumina is then smelted in a reduction furnace using the Hall-H茅roult process, where it is dissolved in molten cryolite and electrolyzed to produce pure aluminum. Finally, the aluminum is shaped and fabricated into various products through methods such as casting, extrusion, or rolling.</p>

- Q: Is it possible to utilize aluminum in the construction of airplanes to enhance fuel efficiency?

- <p>Yes, using aluminum can make airplanes more fuel efficient. Aluminum is lightweight, which reduces the overall weight of the aircraft, leading to lower fuel consumption. Additionally, aluminum has good strength-to-weight ratio and is resistant to corrosion, making it a popular material in aircraft construction. However, it's important to note that the use of aluminum must be balanced with other materials to ensure structural integrity and safety.</p>

- Q: This question asks for methods to decrease the intake or contact with aluminum, a common element that can have health implications if exposed to in large amounts.

- <p>To reduce aluminum exposure, consider the following strategies: 1) Use a stainless steel or glass water bottle instead of aluminum cans. 2) Avoid non-stick cookware with aluminum as a base layer. 3) Choose natural deodorants and antiperspirants without aluminum compounds. 4) Opt for glass or stainless steel food storage containers over aluminum foil or cans. 5) Limit consumption of processed foods, as they often contain aluminum-based additives. 6) Filter your drinking water to remove aluminum. 7) Be mindful of personal care products and choose those free from aluminum. By implementing these changes, you can significantly lower your daily aluminum intake.</p>

Send your message to us

Non-Stick Round Aluminum Circle Disc DC/CC

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords