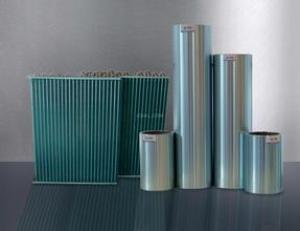

Aluminum Cable Wrapping Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick details of Cable Wrapping Aluminium Foil

Alloy: 1145/1200/1235/1100/1050/8011

Temper: Soft

Specifications of Cable Wrapping Aluminium Foil

Thickness & Tolerance: 0.1 mm - 0.02 mm (+/-6%)

Width & Tolerance: 200 - 1650 mm (+/-1 mm)

Mechancial Properties: Tensile Strength (U.T.S.)≥60 Mpa, Elongation)≥10%

Standard: GB/T3198 / ASTM-B209 / EN546

Usage/Application of Cable Wrapping Aluminium foil

Electrical Cable and Wire

Packaging & Delivery of Cable Wrapping Aluminium Foil

- Q: This question asks for various applications of recycled aluminum other than its traditional uses.

- <p>Recycled aluminum has a wide range of alternative uses. It can be used in the manufacturing of new aluminum products, reducing the need for raw materials. It's also used in construction for window frames, doors, and roofing. In the automotive industry, recycled aluminum is used for car parts, helping to reduce vehicle weight and improve fuel efficiency. Additionally, it's utilized in the aerospace industry for lightweight aircraft components. Recycled aluminum is also found in everyday items like cans, foil, and packaging materials. Furthermore, it's used in electrical components due to its excellent conductivity, and in the production of bicycles and sports equipment for its strength and lightweight properties.</p>

- Q: This question asks for examples of alloys that have a significant amount of aluminum and are known for their strength and ductility.

- <p>Alloys that are known for their high aluminum content and possess excellent strength and ductility include 6061 aluminum alloy, 7075 aluminum alloy, and 2024 aluminum alloy. 6061 is widely used in structural applications due to its balance of strength, corrosion resistance, and formability. 7075 is one of the strongest aluminum alloys and is used in aerospace and high-strength applications. 2024 is known for its good mechanical properties and is used in aircraft structures and other demanding applications. These alloys leverage the benefits of aluminum, such as low density and high resistance to corrosion, while their specific compositions and heat treatments enhance their strength and ductility.</p>

- Q: Besides other special pots, can other aluminum pots be used?

- Electromagnetic stove pot must be metal pot with magnetic and non-magnetic stainless steel, aluminum pot can not be used.

- Q: Is it dangerous to consume food wrapped in aluminum foil due to the risk of aluminum poisoning?

- <p>There is minimal risk of aluminum poisoning from eating food wrapped in aluminum foil. Aluminum foil is designed to be food-safe and does not easily transfer aluminum to food under normal cooking conditions. However, at extremely high temperatures or when foil is used to cook acidic foods, there might be a slight increase in aluminum exposure. The body naturally excretes excess aluminum, and the small amounts typically ingested from food packaging are not considered harmful. Nonetheless, it's always a good idea to follow proper food handling and cooking practices to minimize any potential risks.</p>

- Q: Is it possible to use aluminum as a material for battery production?

- <p>Yes, aluminum can be used to make batteries. Aluminum-air batteries are a type of metal-air battery where aluminum serves as the anode and undergoes oxidation. These batteries have a high energy density and are environmentally friendly, as they produce minimal waste. However, they face challenges such as water sensitivity and the need for alkaline electrolytes, which limit their practical applications. Research is ongoing to improve their performance and make them more viable for widespread use.</p>

- Q: What are the elements that make up aluminum oxide and what is its chemical formula?

- <p>Aluminum oxide is composed of aluminum and oxygen. Its chemical formula is Al2O3, indicating that it consists of two aluminum atoms (Al) and three oxygen atoms (O). This compound is a widely used industrial material, known for its high melting point and hardness.</p>

- Q: This question asks for the specific temperature at which pure aluminum transitions from solid to liquid state.

- <p>The melting point of pure aluminum is approximately 660.32 degrees Celsius (1220.58 degrees Fahrenheit). This is the temperature at which aluminum changes from a solid to a liquid state under standard atmospheric pressure. The melting point is an important physical property of metals and is crucial in various industrial applications, such as casting and welding.</p>

- Q: This question asks about the impact of using aluminum tools and equipment in the workplace.

- <p>Using aluminum tools and equipment in the work environment can have several effects. Firstly, it can enhance safety due to aluminum's non-magnetic and non-conductive properties, which reduce the risk of electrical hazards. Secondly, aluminum is lightweight, which can decrease fatigue for workers and improve efficiency. Additionally, its corrosion resistance means longer tool life and less frequent replacement, which can save costs. However, aluminum's lower strength compared to some other metals might limit its use in high-stress applications. Overall, the choice to use aluminum depends on balancing these factors with the specific requirements of the work environment.</p>

- Q: Explain the impact of aluminum on the transportation system when it is incorporated into automobiles.

- <p>Aluminum has a significant impact on the transportation system when used in automobiles. It is lightweight, which improves fuel efficiency by reducing the overall weight of the vehicle. This reduction in weight leads to lower emissions, as less fuel is consumed. Aluminum's durability and resistance to corrosion also contribute to the longevity of vehicles, reducing the need for frequent repairs or replacements. Additionally, aluminum's recyclability helps in reducing waste and conserving resources, which is beneficial for environmental sustainability. Overall, the use of aluminum in automobiles enhances performance, reduces environmental impact, and promotes a more sustainable transportation system.</p>

- Q: This question asks about the various applications of aluminum alloys in the automotive industry.

- <p>Aluminum alloys are extensively used in automobiles for their lightweight properties and high strength. They are commonly found in engine components, such as cylinder blocks and heads, to reduce weight and improve fuel efficiency. Aluminum alloys are also used in body panels, wheels, and suspension systems to decrease the overall vehicle weight, enhancing performance and reducing emissions. Furthermore, they are utilized in heat exchangers, such as radiators, and various interior components due to their corrosion resistance and durability. The use of aluminum alloys in vehicles contributes to better fuel economy, improved handling, and reduced environmental impact.</p>

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 250 Million |

| Main Markets | Mid East; North America |

| Company Certifications | ISO 14001:2004;FDA |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20-30 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Cable Wrapping Foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 0 m.t.

- Supply Capability:

- 1000 MT / Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords