Aluminum AA1100 Mill Finished Aluminum Circles CC Quality for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware Description

AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware is made from aluminum coils 1xxx. AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

2. Main features of AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware

a.We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.We can control the delivery time within 35 days.

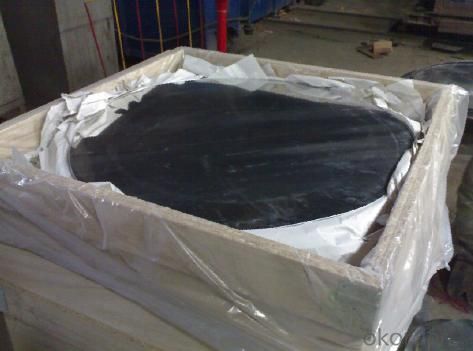

3. AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware Images

4. AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware Specification

Alloy | AA1100 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.5mm -- 4mm |

Diameter | 200mm -- 1200mm |

Standard | GB/T 3880-2006 |

5. FAQ of AA1100 Mill Finished Aluminum Circles CC Quality Used for Cookware

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What other applications can aluminum be utilized for in the manufacturing industry besides common uses?

- <p>Aluminum has a wide range of alternative uses in manufacturing due to its lightweight, corrosion resistance, and strength. It is used in the automotive industry for car parts to reduce weight and improve fuel efficiency. In aerospace, aluminum is crucial for aircraft construction due to its strength-to-weight ratio. It's also used in the construction of buildings for window frames, roofing, and facades. In the packaging industry, aluminum is used for food and beverage cans, as well as pharmaceutical blister packs. Additionally, aluminum is utilized in electrical components like wiring and transformers due to its excellent conductivity. It's also found in various consumer goods, such as bicycles, sports equipment, and electronic devices.</p>

- Q: What is the measure of aluminum's strength, specifically its yield strength and tensile strength?

- <p>Aluminum's strength is typically measured in terms of its yield strength and tensile strength. The yield strength of aluminum varies depending on the alloy and heat treatment, but it generally ranges from 10 to 45 MPa. Tensile strength, which is the maximum stress that aluminum can withstand before breaking, is typically between 90 to 600 MPa for different aluminum alloys. These values make aluminum a lightweight yet strong material suitable for various applications, including construction, automotive, and aerospace industries.</p>

- Q: Explain the impact of aluminum on manufacturing processes in a few sentences.

- <p>The use of aluminum significantly affects manufacturing processes by offering several advantages. It is lightweight, which reduces the weight of products and can lead to fuel efficiency in transportation sectors. Aluminum's high strength-to-weight ratio makes it ideal for structural components. Its excellent thermal and electrical conductivity allows for efficient heat dissipation and electrical transmission. Additionally, aluminum is non-magnetic and non-corrosive, which is beneficial for certain applications. The metal is also easily recyclable, contributing to sustainability in manufacturing. These properties make aluminum a popular choice in industries such as automotive, aerospace, construction, and electronics, enhancing the efficiency and performance of manufacturing processes.</p>

- Q: Can aluminum recycling be done in a closed loop system where the material can be reused indefinitely without loss of quality?

- <p>Yes, aluminum can be recycled in a closed loop system. Aluminum is one of the most recycled materials due to its ability to be recycled indefinitely without losing quality. When aluminum is recycled, it retains its properties, making it suitable for reuse in new products. The closed-loop recycling process involves collecting used aluminum products, melting them down, and then using the recycled material to manufacture new aluminum products. This process can be repeated over and over again, making aluminum recycling highly efficient and environmentally friendly.</p>

- Q: What precautions should be taken when handling or working with aluminum?

- <p>When working with aluminum, several safety measures should be taken: Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and a dust mask to prevent inhalation of aluminum dust. Ensure proper ventilation to avoid the buildup of dust or fumes. Use tools and equipment designed for aluminum to prevent sparks or heat buildup, which can cause fires. Store aluminum in a dry place to prevent corrosion. Always follow the manufacturer's guidelines for handling and processing aluminum, and be aware of the specific hazards associated with the aluminum products you are working with.</p>

- Q: This question asks about the safe usage of aluminum in everyday life.

- <p>Aluminum is widely used in daily life due to its lightweight and corrosion-resistant properties. To use aluminum safely, ensure that aluminum cookware is not used for acidic foods as it may leach aluminum into the food. Avoid storing acidic beverages like soda in aluminum cans for extended periods. Use aluminum foil in moderation, especially when cooking at high temperatures, as it can release aluminum into food. Always wash aluminum utensils thoroughly before and after use. For aluminum cans, recycle them to reduce environmental impact and avoid ingestion of aluminum particles from damaged cans.</p>

- Q: This question asks about the method to determine the strength of aluminum alloy, which is a measure of its ability to withstand stress or deformation before breaking.

- <p>The strength of aluminum alloy is calculated through a series of mechanical tests, primarily the tensile test. In this test, a sample of the alloy is subjected to a gradually increasing tensile force until it fractures. The yield strength is noted at the point where the alloy begins to deform plastically, and the ultimate tensile strength (UTS) is recorded at the point of fracture. The strength is expressed in units of stress (e.g., MPa or psi). Additionally, the hardness of the alloy can be measured using tests like the Brinell or Rockwell hardness test. These values, along with other properties like elongation and reduction of area, provide a comprehensive understanding of the alloy's strength and ductility.</p>

- Q: Does aluminum have the ability to corrode or deteriorate over time?

- <p>Yes, aluminum can corrode, but it typically forms a protective oxide layer on its surface when exposed to air, which prevents further corrosion. This layer of aluminum oxide is very thin but strong and stable, making aluminum highly resistant to corrosion. However, under certain conditions such as exposure to certain chemicals or in the absence of oxygen, aluminum can still corrode. Corrosion can also occur if the protective layer is damaged or compromised.</p>

- Q: This question asks about the methods to guarantee that the aluminum content in products is within safe limits.

- <p>To ensure that products do not contain excessive amounts of aluminum, implement a strict quality control process. This includes sourcing raw materials from suppliers who adhere to strict aluminum content limits, conducting regular testing of products using advanced analytical techniques such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) or Atomic Absorption Spectroscopy (AAS). Establishing and following Good Manufacturing Practices (GMP) is crucial, along with continuous monitoring and improvement of production processes. Additionally, staying updated with regulatory guidelines and setting internal limits that are below the legal maximum levels can help maintain safety and compliance.</p>

- Q: This question asks for recent applications of aluminum in contemporary society.

- <p>Aluminum has found new uses in modern society across various sectors. In the automotive industry, it is used to manufacture lightweight vehicles for fuel efficiency and reduced emissions. In construction, aluminum is utilized for building facades, window frames, and roofing due to its durability and low maintenance. The aerospace industry also relies on aluminum for aircraft construction because of its strength-to-weight ratio. Additionally, aluminum is used in electronics for heat sinks and casings, and in the packaging industry for food and beverage cans. It's also gaining traction in the energy sector, particularly in battery technology for electric vehicles and renewable energy storage solutions.</p>

Send your message to us

Aluminum AA1100 Mill Finished Aluminum Circles CC Quality for Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches