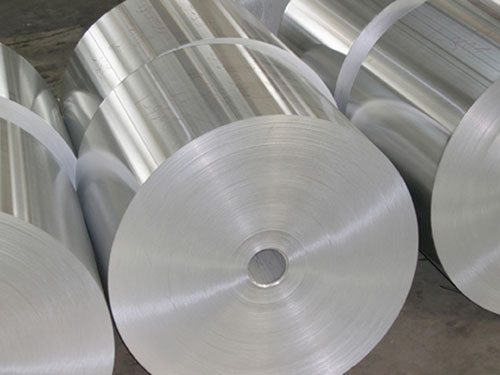

Aluminum 20mic Blister Packing Aluminum Foil 8011-H18 - 0.021mm

- Loading Port:

- CN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 7000MT m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

8011 blister aluminum foil for medicine packing:

OP/Printing/ALU/HSL

Thickness:20-25micron

Length:1000mm

8011 blister aluminum foil for medicine packing :

Applications: Blister packages for Pharmaceuticals products such as capsules, tablets, pill , pastille, small-size food , candy, etc.

Structure and application:protect layer (OP)/Outer printing layer/Aluminum foil based material (AL) inside printing layer/Bond (VC). Use in drugs blister packaging machine.

Performance and the characteristic: Excellent properties such as of anti- oxygen, moisture-proof, leak-proof,carryhome, antipollution, etc. Adopting hard anodized aluminum as cover material, it is easy to break aluminum foil to take out the drugs by pushing the cover. Adopting heat-seal coating material, which cannot be stripped,it can be bonded with all kinds of plastic-based materials.

According to printing method:

plain foil(no printing), printing foil (one-sided printing, two sided printing,single color print,double color printing, polychrome printing), color foil (one-sided golden color, two sided golden color,green bottom color,each kind of colored bottom color), forgery-proof (stealth writing, design, positive and negative printing).

Product shape: roll material.

Structures : OP (Protective layer) / Print Layer/ AL(Aluminum layer)/VC(agglutinate layer)

Specification:

Width: less than 1000mm,

Thickness: 0.02 to 0.025mm

Inner hole diameter : 76mm/152mm,

Outer diameter: 240-280mm, Length/roll:1000mm-2000mm (according to different requirement). One side is for sealing with pvc or pvc/pvdc film and other side is for printing.one side is bright and other side is dull.

Functions: High obstruction, Heat insulation, Air tightness, Printable, Breakable in slightly.

Characters: Our goods are well sealed for pinholes, coating is average with heat insulation, print is clear and beautiful with shining.

Applications: it can be applied to blister packing for capsules, pills, suppositories and mini-foods/candies, chocolate, chutty and so on.

Packing:each roll to be wrapped with sack polyethylene.outer packing:carton packing,wrap by film then pallet packing.

Why Us:

• More than 10 years experience, USD 800 million sales every year.

•Good quality control in production process,

• Excellent quality and Competitive price, OEM is available.

• Available in an extensive range of stock or custom size.

• Any port in China available.

• MOQ can meet your promotional business very well.

Trade Terms:

• Payment: T/T 30% in advance, balance against copy of B/L,Western Union.

• Production Lead Time: 5-7 after deposit paid.

• Shipping Methods: Oean carriage

• If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

Our Service:

• Your inquiry related to our product & price will be replied within 24hours.

• Well-trained & experienced staff are to answer all your inquiries professional in English of course.

• Working time: 8:30am - 17:30pm, Monday to Saturday (UTC+8).

• OEM is highly welcomed. We have strong R&D team here to help.

• Your business relationship with us will be confidential to any third party.

• Good after-sale service offered, please get back if you got question.

Suggestion:

Please kindly check the packages after you receive the goods, if you got wrong products/ quality problem/ short q'ty, please get back to us as priority. Please note that you need to send us pictures of the defective items concerning this, and we will consider to replace or refund accordingly.

- Q: This question asks about the health effects of consuming aluminum on human health.

- <p>Aluminum consumption can have various effects on human health, though the extent of its impact is still a subject of debate among researchers. High levels of aluminum intake have been associated with neurological disorders, particularly Alzheimer's disease, although a direct causal link has not been definitively established. Aluminum can also interfere with bone health, potentially leading to osteoporosis, and may affect the kidneys, causing dysfunction. It is important to note that the human body naturally excretes aluminum, so moderate exposure is generally not harmful. However, excessive intake, especially over a long period, could pose health risks.</p>

- Q: What is the oxide layer that forms on aluminum and what are its properties?

- <p>The oxide layer on aluminum is a thin, transparent, and hard layer of aluminum oxide (Al2O3) that forms naturally when aluminum is exposed to air. This layer is highly resistant to corrosion and protects the underlying aluminum from further oxidation. It is chemically inert, which means it does not react easily with other substances, and it has a high melting point, making it stable at high temperatures. The oxide layer also has a high hardness, which helps to prevent scratching and wear. This protective oxide layer is self-healing, meaning that if it is damaged, it can regenerate and continue to protect the aluminum.</p>

- Q: This question asks for the current cost of aluminum.

- <p>The cost of aluminum fluctuates based on market conditions and can vary by region. As of my last update, the price of aluminum was around $2,500 per metric ton, but this is subject to change. For the most accurate and up-to-date pricing, it's best to check with a commodity exchange or a reliable financial news source. Prices can be influenced by supply and demand, economic indicators, and geopolitical factors.</p>

- Q: Describe the steps involved in the manufacturing of aluminum sheets.

- <p>The process of manufacturing aluminum sheets involves several key steps. Initially, aluminum ore, typically bauxite, is mined and then processed to remove impurities. The purified aluminum oxide is then dissolved in a cryolite bath at high temperatures, a process known as the Hall-H茅roult process. This results in molten aluminum, which is then cast into ingots. These ingots are reheated and passed through rollers to gradually reduce their thickness, creating aluminum sheets. The sheets are then cooled, cut to size, and may undergo further treatments like annealing or coating, depending on their intended use. The final product is a flat, thin sheet of aluminum ready for various applications.</p>

- Q: Is it possible to use aluminum as a material for battery production?

- <p>Yes, aluminum can be used to make batteries. Aluminum-air batteries are a type of metal-air battery where aluminum serves as the anode and undergoes oxidation. These batteries have a high energy density and are environmentally friendly, as they produce minimal waste. However, they face challenges such as water sensitivity and the need for alkaline electrolytes, which limit their practical applications. Research is ongoing to improve their performance and make them more viable for widespread use.</p>

- Q: This question asks for a list of typical flaws or imperfections that can occur in aluminum products.

- <p>Common defects in aluminum products include porosity, which refers to small holes or voids within the material; surface defects such as scratches, dents, and discoloration; mechanical defects like warping or deformation; and metallurgical defects such as inclusions or impurities. Additionally, aluminum products can suffer from corrosion, which can lead to pitting or general surface degradation, and stress corrosion cracking, which occurs under certain environmental conditions and stress. Each of these defects can impact the structural integrity, appearance, or performance of aluminum products.</p>

- Q: Is it possible to recycle aluminum from old products to create new ones?

- <p>Yes, aluminum can be recycled to make new products from old ones. Recycling aluminum is a highly efficient process that requires only 5% of the energy needed to produce new aluminum from raw materials. This process is not only environmentally friendly but also economically viable. Recycled aluminum maintains its quality and can be used to create a wide range of new products, from cans and packaging to automotive parts and construction materials.</p>

- Q: This question asks for an explanation of the process involved in the production of aluminum foil.

- <p>Aluminum foil is made through a process that starts with the extraction of aluminum from its ore, bauxite. The bauxite is refined to produce aluminum oxide, which is then reduced to aluminum using the Hall-H茅roult process. The aluminum is then melted and cast into large ingots. These ingots are heated and rolled into thin sheets using large industrial rolling mills. The aluminum is rolled multiple times, each pass reducing its thickness until it reaches the desired foil thickness. The final thin sheets are then cut and packaged as aluminum foil. This process requires precision and control to ensure the foil is uniform and free of defects.</p>

- Q: This question asks about the impact of adding zinc to aluminum alloys and how it changes their characteristics.

- <p>Adding zinc to aluminum alloys significantly enhances their mechanical properties, particularly strength and hardness. Zinc increases the alloy's resistance to deformation, making it more suitable for applications requiring high strength-to-weight ratios. This addition also improves the alloy's resistance to corrosion, especially in marine environments. However, it's important to note that excessive amounts of zinc can lead to a decrease in ductility and increase the risk of cracking, especially during welding or heat treatment processes. The addition of zinc also affects the alloy's thermal conductivity and electrical conductivity, typically reducing both. Overall, the addition of zinc to aluminum alloys is a balancing act to achieve desired properties for specific applications.</p>

- Q: What are the various electronic components that utilize aluminum as a primary material?

- <p>Aluminum is used in several types of electronic components due to its good thermal conductivity, lightweight, and corrosion resistance. Some of the common components include: 1. Capacitors: Aluminum electrolytic capacitors are widely used for their high capacitance and low cost. 2. Heat sinks: Aluminum is a popular choice for heat sinks due to its ability to dissipate heat efficiently. 3. Semiconductors: Aluminum is used in semiconductor manufacturing, particularly for interconnects and as a barrier layer. 4. Conductive adhesives: Aluminum-filled adhesives are used for bonding components in electronics. 5. Wires and cables: Aluminum wire is used in some applications due to its lower weight compared to copper. 6. Reflectors: Aluminum is used in light reflectors for its reflective properties. 7. Housings and enclosures: Aluminum is used in the construction of electronic device casings for its strength and lightweight properties.</p>

Send your message to us

Aluminum 20mic Blister Packing Aluminum Foil 8011-H18 - 0.021mm

- Loading Port:

- CN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 7000MT m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords