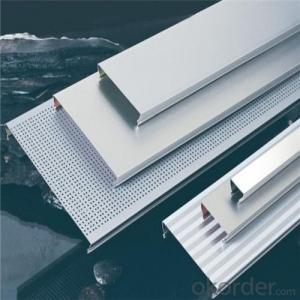

Aluminium Metal Ceiling, C-Shaped strip Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

Designed and engineered to perform in multiple commercial environments under multiple stresses, cmax Metal Ceiling systems allow cutting-edge technologies to be applied to the most modern or traditional designs. Every component is designed and fabricated to exacting specifications and the highest manufacturing standards.

Ceiling Type | Size(mm) | Height(mm) | Thickness(mm) | Edge Type |

Clip In Ceiling | 300*300 | 18/20 | 0.45~0.56 | Beveled Edge/Square Edge |

600*600 | 20/24/28 | 0.45~0.7 | Beveled Edge/Square Edge | |

800*800 | 20/24/28 | 1.0 | Beveled Edge/Square Edge | |

300*1200 | 20/24/28 | 0.75~0.9 | Beveled Edge/Square Edge | |

600*1200 | 20/24/28 | 0.75~1.1 | Beveled Edge/Square Edge | |

Lay In Ceiling | 275*275 (295*295) | 8 | 0.60~0.70 | Square Edge |

575*575 (595*595) | 8/12/18 | 0.60~0.70 | Beveled Edge/Square Edge | |

585*585 (595*595) | 10 | 0.60~0.70 | Square Edge | |

585*585(605*605) | 10 | 0.60~0.70 | Square Edge | |

595*1195*575*1175 | 8 | 0.60~0.70 | Square Edge | |

603*1210*585*1195 | 8 | 0.60~0.70 | Square Edge | |

Ceiling Type | Open size(mm) | Width & Height(mm) | Thickness(mm) | Length(mm) |

Open Cell Ceiling | 50*50 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 |

75*75 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

100*100 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

125*125 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

150*150 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 1950 | |

200*200 | Width:10/15 Height:35/40/45/50/60/80 | 0.35~0.6 | 2000 | |

Ceiling Type | Width(mm) | Length(mm) | Thickness(mm) | Edge Type |

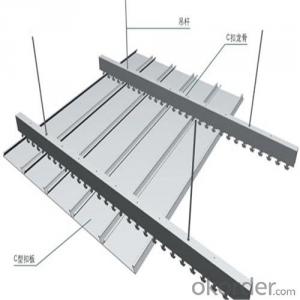

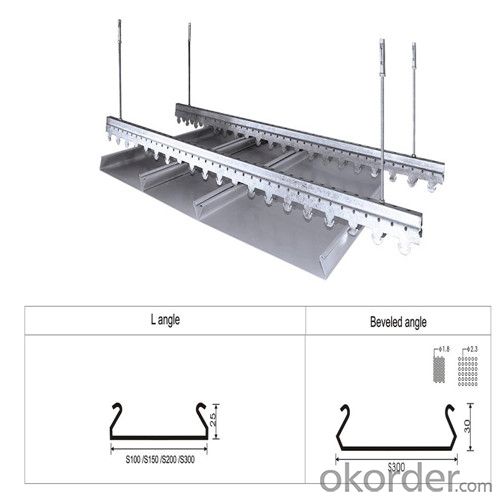

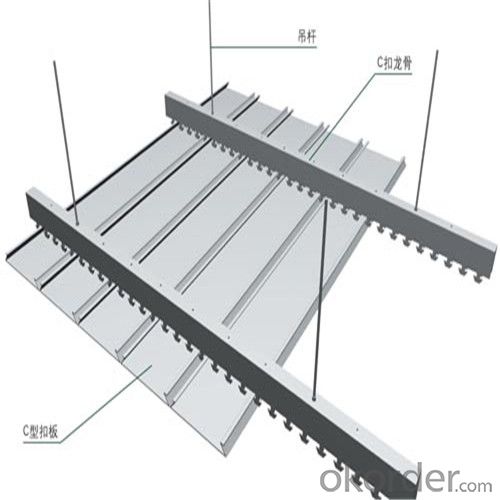

C-strip | C100/C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

S-strip | C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

H-strip | C150/C200/C300 | 1000~6000 | 0.45~0.85 | Beveled Edge/Square Edge |

G-strip | C100 | 1000~6000 | 0.45~0.85 | Square Edge |

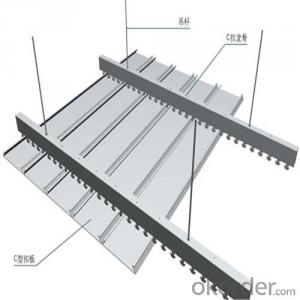

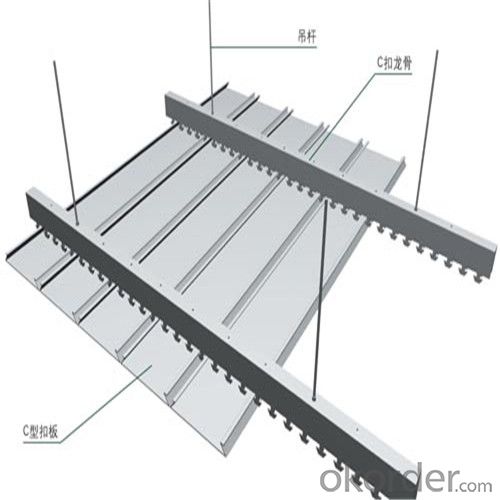

Installation and Accessories

The Lay in (I) system is easy to match grid system. The panels are right angle by 8mm chamfer. It's 100% upward accessible and installed on either silhouette grids or other 9/16" (15mm) exposed tee grids, forming unique overall effect. The silhouette grids also can offset manufacturing tolerance and installation tolerance. Also, it can be combined with mineral fiber panels to present a various installation effect.

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: How about the quality of the ceiling

- The second generation of PVC is the first generation of the product.

- Q: What is the brushed aluminum plate

- Aluminum plate is made of aluminum alloy plate, through the open material, shear angle, molded, aluminum plate surface using a variety of different coating processing to get a variety of aluminum plate products, aluminum slab plate, the most important two Type, one is home improvement integrated Lvkou Ban, the other is the engineering Lvkou Ban, home-made aluminum slab board mainly to roll and frost the main series of two, with the development of home improvement integrated aluminum plate has been Variety of different processing technology are used to them, such as thermal transfer, glazed, ink printing, mirror, 3D and so on series is the most popular in recent years, home improvement integrated aluminum slab plate, home improvement integrated aluminum plate is Board surface fancy, service life, board advantage and so on to obtain market recognition, engineering aluminum slab board is commonly used roller coating, powder coating, film, scrub and other surface coating, the surface is relatively simple, the color is solid , Of which milky white is the most expensive to use aluminum slab plate, engineering aluminum plate to buy the most important depends on the coating, coating color protection is the primary consideration, the coating to maximize the life to ensure that the owners interest.

- Q: What are the properties of aluminum?

- Aluminum reflection of the light is also very good, reflective UV than silver, aluminum more pure, the better the ability to reflect, it is often used to create high-quality mirrors, such as solar cookers and so on.

- Q: Exhibition hall ceiling aluminum grid 3d is how to do

- In fact, with the other curtain wall concealed works the same practice, concealed works will be closed after the invisible place to the supervision and acceptance, and confirmed on the acceptance can be, the glass curtain wall is basically covered by the part of the hidden layer of the hidden , The information around the electronic dog has.

- Q: Figure, 600 * 600 or 300 * 300 aluminum buckle plate can not make such a light groove, the edge is not used to close the edge of the edge? Not much, thanks for the answer!

- If you really want to use aluminum buckle board, you can try to use matt aluminum slab.

- Q: The designer advised us to use the gypsum board on the toilet, said nice, the atmosphere. Because we are in the top floor, does not affect the leakage, we first decoration, good tangled, such as gypsum board, then the cost will be much higher? Please experts to give advice.

- I was decorating, the bathroom ceiling never used gypsum board, the bathroom water vapor weight, gypsum board will suffer after damp

- Q: Home improvement aluminum plate thickness in the end is how much is considered good

- Home decoration aluminum plate is not necessarily thick like.

- Q: Balcony ceiling is good or an aluminum button board good?

- Ye just do waterproof,

- Q: Including: hook, triangular keel connection, nut, big hanging, income side, triangular keel, expansion screw, screw, the main keel (light steel keel) Should have 35 square meters, how much you need, the best price it!

- Almost need 6-7 hundred dollars

- Q: How to handle between two different levels of aluminum slabs

- The main keel above the top with a screw hanging on the roof, but also at least stay 1-2 cm height, that is, at least you the height of the board and the roof to stay 7CM or so, and this is still you do not install Yuba Circumstances, if you want to install Yuba, it would be 10 centimeters.

Send your message to us

Aluminium Metal Ceiling, C-Shaped strip Panel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords