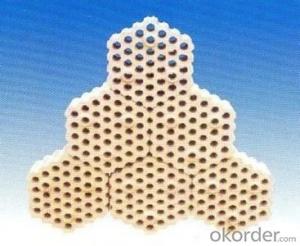

Corundum Alumina Chrome Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Index | JZGK-N | JZGK-S | |||

Standard | Typical | Standard | Typical | ||

Bulk Density,g/cm3 | ≥ 3.30 | 3.32 | ≥ 3.20 | 3.20 | |

Apparent porosity,% | ≤ 14.0 | 12.5 | ≤ 17.0 | 16.5 | |

Cold Crushing Strength(C.C.S),Mpa | ≥ 100.0 | 103.8 | ≥ 60.0 | 75.0 | |

Refractories Under Load,°C | > 1700 | > 1700 | > 1700 | > 1700 | |

Thermal Shock Resistance[TSR] 1100 °C × Water | 5 | 5 | 8 | 8 | |

Chemical Composition,% | Al2O3 | ≥ 80.0 | 84.5 | ≥ 80.0 | 82.3 |

Cr2O3 | ≥ 12.0 | 13.7 | ≥ 12.0 | 13.4 | |

Application | Used in coke slurry and coal slurry boilers | ||||

Quick Details

| Place of Origin: | China (Mainland) | Shape: | Brick | Material: | Chrome |

| Al2O3 Content (%): | 80% min | Refractoriness (Degree): | 1770°< Refractoriness< 2000° | CrO Content (%): | 13% min |

| Model Number: | RF-LG-8013 | Brand Name: | Luoyang refractory |

Packaging & Delivery

| Packaging Detail: | wooden pallet or as customer's request |

| Delivery Detail: | Within 30-40 days |

Specifications

1.High-middle grade refractory materials

2.Manufacturer for refractories

3.Stable quality

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- AZS33 is the casting of AZS series of the largest, most widely used in tea, to prevent the pollution of liquid glass is excellent. Widely used in the glass furnace pool wall, pool bottom, the upper structure and feeding routes and other parts.

- Q: Application of electric high temperature regulating valve?

- Now, the definition of refractories has not only depended on the degree of refractoriness is more than 1580 degrees celsius. At present, refractory materials refer to inorganic non-metallic materials used in metallurgy, petrochemical, cement, ceramics and other production equipment lining.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- Fused zirconia corundum brick is pure alumina and zirconia containing silica 65%, about 34% of the zircon sand in electric furnace melting after internalization into moulds cooling and the formation of the white solid, the petrographic structure by zirconium corundum and plagioclase eutectoid and glass phases, from the phase is eutectoid zirconium corundum and plagioclase phase, glass phase filling between their crystallization.

- Q: What is the main component of corundum?

- Corundum is the main component of Al2O3, often containing trace impurities such as Cr, Ti, Fe, V and so on.

- Q: What does refractory consist of?

- According to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: Can the PE sintering plate dust collector be suitable for dust removal in the coking plant?

- Do not know where the coking plant do dust treatment, processing conditions are different, the dust collector is not the same

- Q: What are the main constituents of refractory bricks?

- Brick, refractory brick is containing more than SiO293%, is the main varieties of acid resistant brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: What kind of refractory material will be used in the glass kiln?

- The content of ZrO2 in the brick is about 66%, and the bulk density is 3.7g/cm3, which has better thermal stability and anti stripping property. The use of erosion serious investment outlet area and after the parapet wall in the powder melting furnace, observation hole brick and pathway of flame space and roof parapet wall brick, brick burner. But there are also AZS burner brick with mullite brick for brick kiln and transition two side clearance brick etc..

- Q: Can the fire clay be reused?

- Refractory soil cannot be reused.Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

Send your message to us

Corundum Alumina Chrome Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords